Gas piping, Pl~1 – Carrier 58SS/DH User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

RETURN OR

SUPPLY AIR

pl~1

VENT TO ROOF

I

I I

I I I

I

I

I

* MINIMUM OPENING SIZE IS 100 SO IN.

(REUIRN

+ MINIMUMOF 3 IN. WHEN TYPE-BI VENT IS USED. AIR ONLY)

Fig. 1 — Upflow or Counterflow, Using Air

from Inside Building

I so IN. PER

4000 BTUH

DUCTS

TO ROOF

I I

I I

12 IN. MAX

T

I

so

IN. PER

2000 BTUH

DUCTS TO

OUTSIDE

I SO IN. PER

2000 BTUH

±

12 IN. MAX

T

i

VENT

TO ROOF

RETURN

OR

SUPPLY

AIR

13

-12 IN.MAX

RETURN OR

SUPPLY AIR

J

5

I so

IN. PER

4000 BTUH

DUCT

TO OUTSIDE

USE ANY OF THE FOLLOWING COMBINATIONS

OF OPENINGS; AaB CSD D8E

Fig. 2 — Upflow or Counterflow, Using Air

from Outside Building

GAS PIPING

Gas piping must be installed in accordance with

national and local codes.

The gas supply line should be a separate line directly

from the meter to the furnace, if possible. Referto Table 1

for recommended gas pipe sizing.

Table 1 — Maximum Capacity of Gas Pipe*

NOMINAL

IRON PIPE

SIZE

(in.)

INTERNAL

DIAMETER

(in.)

LENGTH OF PIPE (ft)

10

20

30

40

50

'k

0 622

175

120

97

82

73

%

0.824

360

250

200

170

151

1

1.049

680

465

375

320

285

r/4

1 380

1400

950

770

660

580

1V2

1 610

2100

1460

1180

990

900

'Cubic ft of gas per hour for gas pressure of 0.5 psig or less, and a

pressure drop of 0.5 in wg (based on a 0 60 specific gravity)

Ref. Table C-4 NFPA 54-1984.

Avoid low spots in long runs of pipe. It is best to slope

all pipe I/4inch in 15 ft to prevent traps. All horizontal

runs should slope away from the meter, to risers. Risers

should be used to connect to the furnace and to the meter.

Joint compounds (pipe dope) should be applied

sparingly and only to the male threads of the joints.

Consult local supplier for type of compound to be used.

This pipe dope must be resistant to the action of LP

(propane) gas.

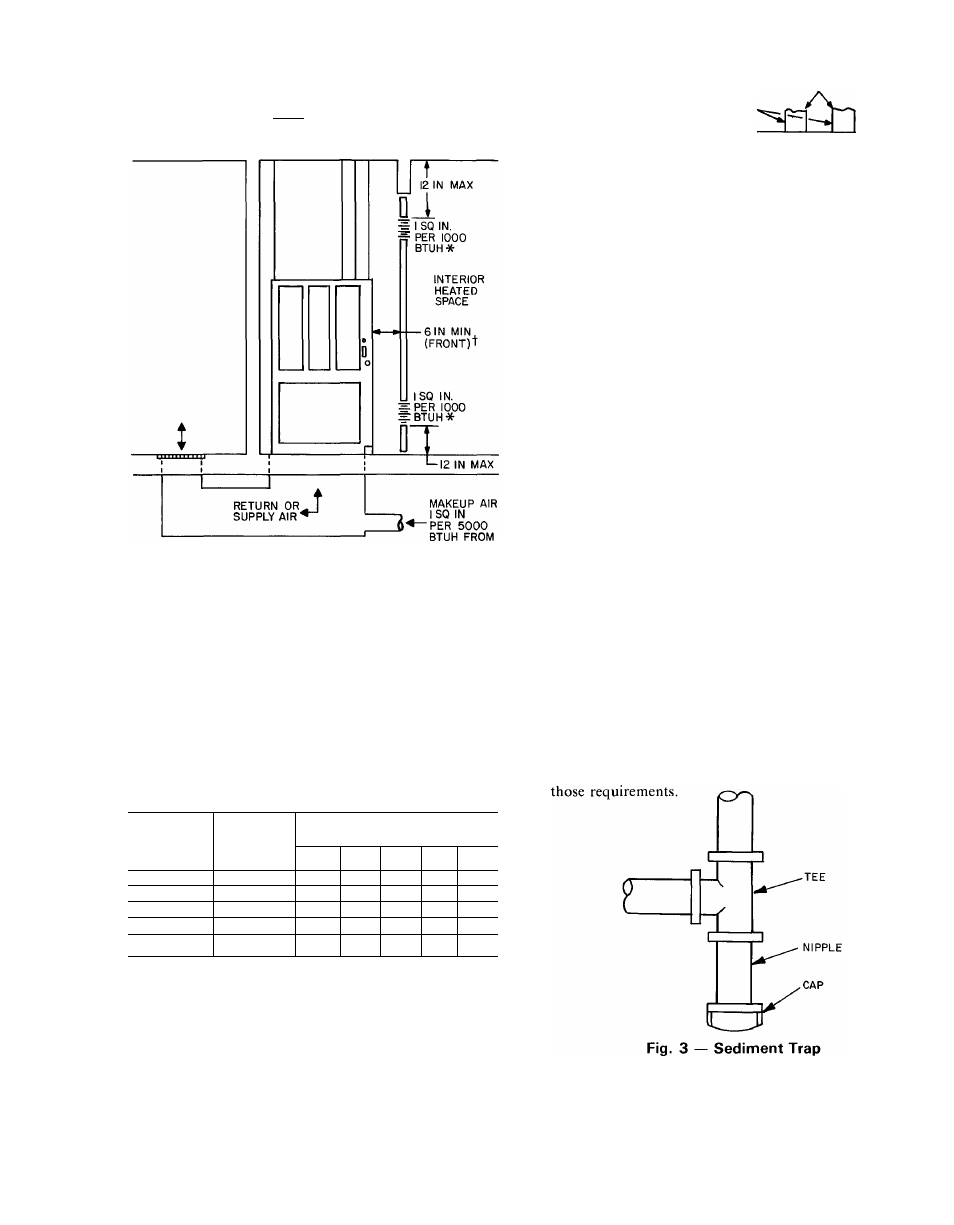

Install a sediment trap in the riser leading to the

furnace. This trap collects dirt or condensate. It can be

installed by connecting a Tee to the riser leading to the

furnace, so that the straight through section of the Tee

is vertical. Then connect a capped nipple into the lower

end of the Tee. The capped nipple should extend below

the level of the gas controls. See Fig. 3. Where a gum filter

is required by local codes, install it in accordance with

An accessible manual shutoff valve shall be installed

upstream of the furnace gas controls and within 6 ft of the

furnace. A 1/8-in. NPT plugged tapping, accessible for

test gage connection, must be installed immediately up

stream of the gas supply connection to the furnace, and

downstream of the manual shutoff valve.