A warning, A caution, Venting – Carrier 58SS/DH User Manual

Page 4: Common venting with other appliances

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

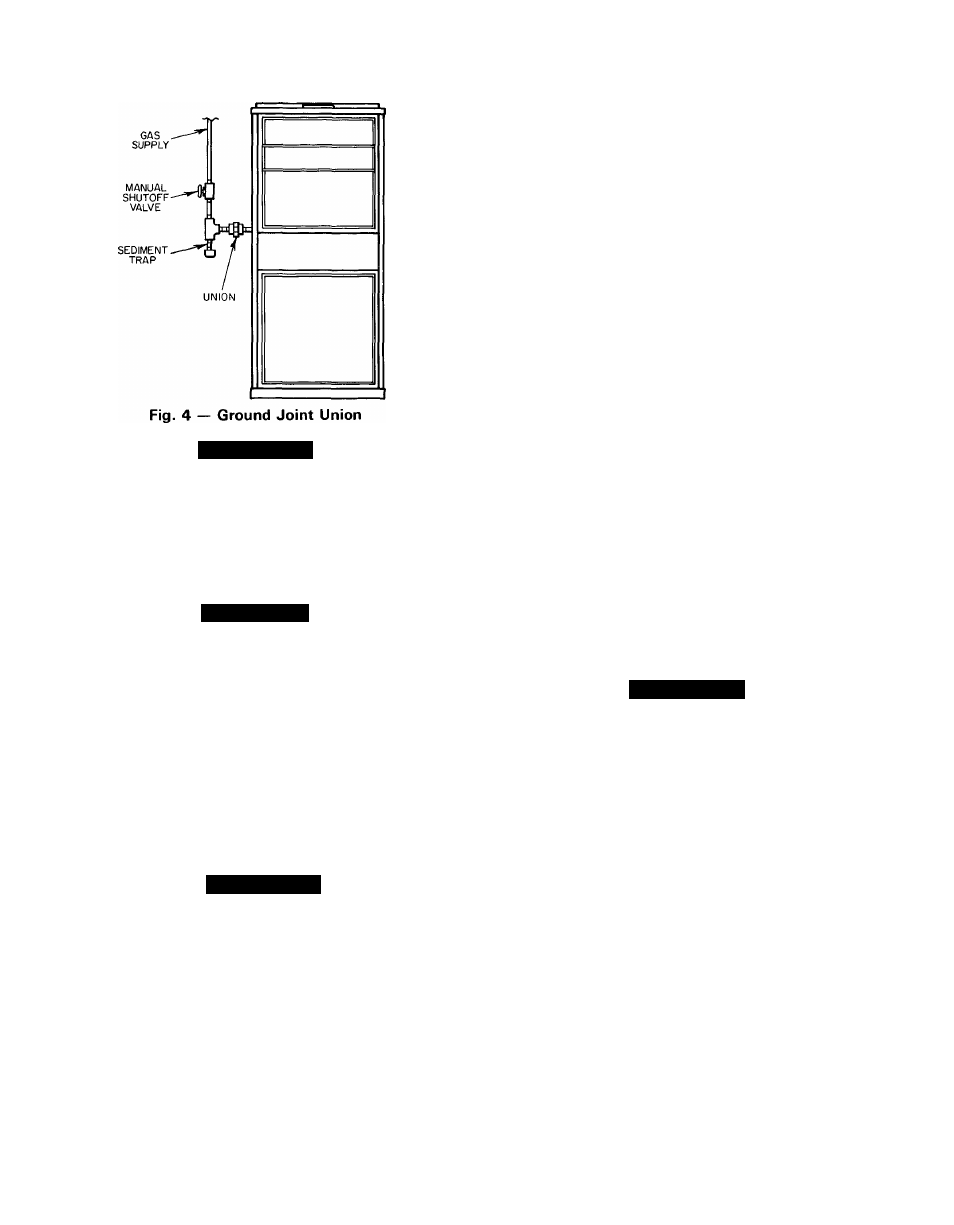

Place a ground joint union between the gas control

manifold and the manual gas shutoff valve. See Fig. 4.

A WARNING

Use the proper length of pipes to avoid stress on the

gas control manifold.

Protect all segments of the piping system against

physical and thermal damage. Support all piping with

appropriate straps, hangers, etc. Use a minimum of one

hanger every 6 feet. For pipe sizes larger than l/2in.,

follow recommendations of national codes.

A CAUTION

If a flexible connector is required or allowed by the

authority having jurisdiction, black iron pipe shall

be installed at the gas valve and extend a minimum of

2 in. outside the furnace casing.

Piping should be pressure tested in accordance with

local and national plumbing and gas codes before furnace

has been attached. If pressure exceeds 0.5 psig(14in. wg),

gas supply pipe must be disconnected from furnaee before

pressure test. If test pressure is equal to or less than 0.5

psig (14 in. wg), close manual shutoff valve located on gas

valve before test. Ground joint union should be loosened

before pressure testing.

After all connections have been made, purge the lines

and check for leakage.

A

WARNING

Never purge a line into a combustion chamber. Never

use matches, candles, flame, or other sources of

ignition for the purpose of checking leakage. Use a

soap-and-water solution to cheek for leakage.

VENTING

■ Venting Category I

— This furnace complies with

Venting Category 1, as noted on the furnace rating plate.

This refers to the type of venting system as specified in the

ANSI 21.47 requirements, against which this appliance is

tested and design certified by the American Gas Associa

tion Laboratories. Specifically, Venting Category 1 is a

nonpositive venting system, meaning the static pressure

in the vent is less than atmospheric pressure, and the stack

gas temperature is at least 140 degrees F above the dew

point temperature. Do not attempt to confirm this data

by field measurement, as specific laboratory equipment

and test conditions are required.

Consult local codes. For additional information refer

to the National Fuel Gas Code (NFPA No. 54-1984 or

ANSI Z223.1-1984). Unless the local codes direct other

wise, unit may be vented to an NFPA-or ANSI-approved

chimney, or to a listed type-Bl gas vent. Connect the

vent collar to the chimney or gas vent to be used. Follow

these recommendations:

1. Select flue connection material that is satisfactory

for installation and that meets requirements of local

codes.

2. Flue connection pipe must be at least as large as

outlet collar on furnace. No reduction in this size is

permissible in pipe run.

NOTE: The clearance requirements which must be

maintained between the furnace vent pipe and com

bustible materials are as follows: 6 in. for single-wall

vent and one in. for type-Bl (double-wall) vent.

When B1 vent material is used, make the single wall-

to-B 1 transition with a listed transition fitting

directly on the flue collar or flue extension pipe.

3. Run pipe as directly as possible with minimum

number of turns and minimum of 12 in. straight pipe

before the first bend (upflow and downflow).

4. Maintain minimum of 1/4in. per linear ft upward

slope on all horizontal runs.

5. Rigidly support flue pipe with hangers and straps to

ensure that there will be no movement after

installation.

6. Insert smallest flue connection pipe at highest level

consistent with available headroom or clearance to

combustible materials, when 2 or more vent eon-

nectors enter a common gas vent or chimney flue.

7. Extend flue connection pipe through chimney wall

flush with inner face of chimney liner and above

extreme bottom to avoid restriction.

A

WARNING

Never connect into a chimney serving a fireplace

unless the fireplace opening is sealed off.

10

.

8. No portion of venting system shall extend into, or

pass through, any circulating air duct or plenum.

9. Chimney or gas vent shall extend at least 5 ft above

highest connected draft hood and should extend high

enough above roof or neighboring obstruction, so

that wind from any direction will not create positive

pressure in vicinity of chimney or gas vent outlet.

Chimney or gas vent should extend 3 ft higher than

point of emergence through roof, and at least 2 ft

higher than any object within a radius of 10 feet. See

Fig. 5.

A type-B 1 gas vent shall terminate above roof surface

with a listed cap or roof assembly.

Common Venting with Other Appliances —

This furnace may be connected to a common chimney or

listed type-Bl gas vent with other listed gas-fired appli

ances. The vent system of this induced-draft furnace

operates at negative pressure during normal operation. If

for any reason the pressure in the vent system becomes

positive (may happen if chimney is inadvertently

blocked), the furnace shuts down and locks off. This is

accomplished by means of draft safeguard switch located

on tube attached to relief box just above draft inducer

blower. The design of this furnace, equipped with draft

safeguard switch, has been tested by the American Gas

Association Laboratories.