Carrier 542E User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

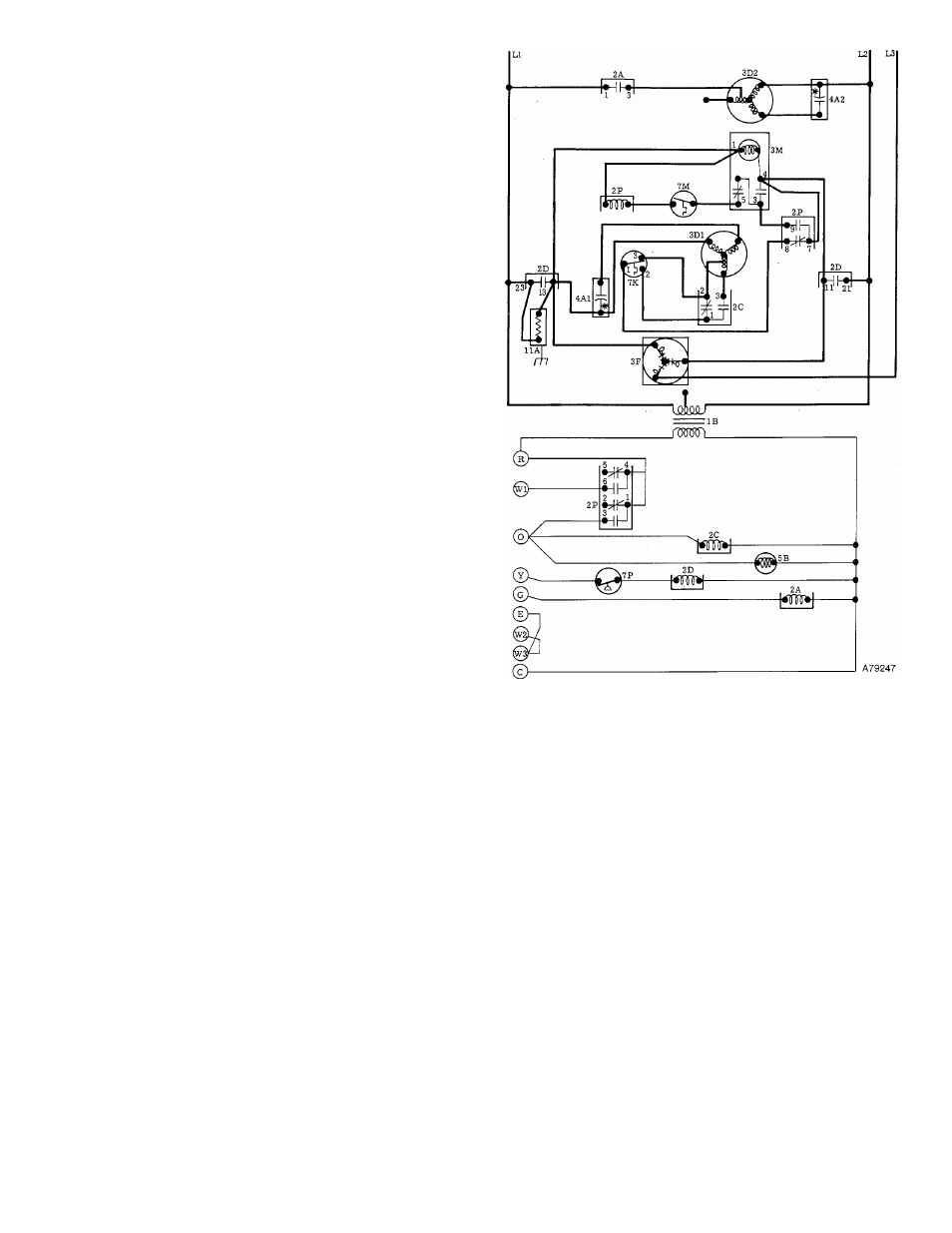

LEGEND

I B-Transformer

2A-lndoor Blower Relay SPST (N.O.)

2C-Outdoor Fan Relay SPOT

2D-Compressor Contactor DPST (N.O.)

2P-Defrost Relay TPDT

3D1-Outdoor Fan Motor

3D2-lndoor Blower Motor

3F-Com pressor

3M-Defrost Timer

4A1-Fan Motor Capacitor

4A2-Blower Motor Capacitor

5B-Reversing Valve Solenoid

7K-Fan Switching Thermostat

SPOT

7M-Defrost Thermostat

Switch (N.O.)

7P-Low-Pressure Switch

SPST (N.O.)

II A-Crankcase Fleater

2. Inspect coils, drain pan, and condensate drain annually.

Clean when necessary.

3. Inspect blower motor and wheel for cleanliness, and

check lubrication annually. Clean and lubricate when

necessary.

4. Check electrical connections for tightness and controls

for proper operation annually. Service when necessary.

WARNING: A failure to follow these warnings could result

in serious personal injury:

1. Disconnect electrical power to the unit before perform

ing any maintenance or service on the unit. (There may

be more than one disconnect switch.)

2. Use extreme caution when removing panels and parts.

As with any mechanical equipment, personal injury can

result from sharp edges, etc.

A. Unit Top Removal

WARNING: Removal of the unit top must never be at

tempted by anyone other than qualified technicians.

CAUTION: The outdoor fan and motor are fastened to the

unit top. When removing the top, use extreme care to not

pull the fan motor leads loose.

NOTE: When performing maintenance or service procedures

that require removal of the unit top, be sure to perform all of

the routine maintenance procedures that require top

removal; including coil inspection and cleaning, and conden

sate drain pan inspection and cleaning.

When performing maintenance and service procedures that

require unit top removal, refer to the following top removal

procedures:

1. Disconnect electric power to unit.

2. Remove all screws that secure unit top, including

screws around four sides and those on top that screw

into internal divider panels. Save all screws.

3. Tape all side panels at each seam near unit top. Use tape

strips that are at least 5 inches long to prevent sides

from falling when top is removed.

4. Lift top from unit carefully. Set top on edge and ensure

that top is supported by unit side that is opposite duct

(or plenum) side. Use extreme care to prevent damage to

fan blades, motor, insulation, and coils.

5. Carefully replace and secure unit top to unit, using

screws removed in step 2 when maintenance and/or

service procedures are concluded. (Be sure to use origi

nal screws that have rubber washers to seal out water

when securing top to internal divider panels.)

Figure 13—Typical Line-to-Line Wiring Diagram

B. Air Filter

CAUTION: Never operate the unit without a suitable air

filter in the return-air duct system. Always replace the filter

with the same size and type. See Table I for recommended

filter sizes. '

Inspect air filter(s) at least once each month and replace

(disposable-type) or clean (cleanable-type) at least twice

during each heating and cooling season or whenever the

filter (s) become clogged with dust and lint.

Model 542E units do not have factory-supplied air filters.

The field-supplied air filter(s) may be either disposable or

cleanable. Model 542D units have two factory-supplied, dis

posable-type air filters located in the plenum section of the

unit. Remove the access door on the return-air inlet side of

the plenum to gain access to the filters. See Figure 4. Re

place these filters with the same size and type when

necessary.

C. Direct-Drive Indoor Blower and Motor

For longer life, operating economy, and continuing efficien

cy; clean accumulated dirt and grease from the blower wheel

and motor annually.

Lubricate the motor every 5 years if the motor is used inter

mittently (thermostat FAN switch in AUTO position), or

every 2 years if the motor is used continuously (thermostat

FAN switch in ON position).

WARNING: Disconnect electrical power to the unit before

cleaning and lubricating the blower motor and wheel.

-

1 5

-