D. unit controls – Carrier 542E User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

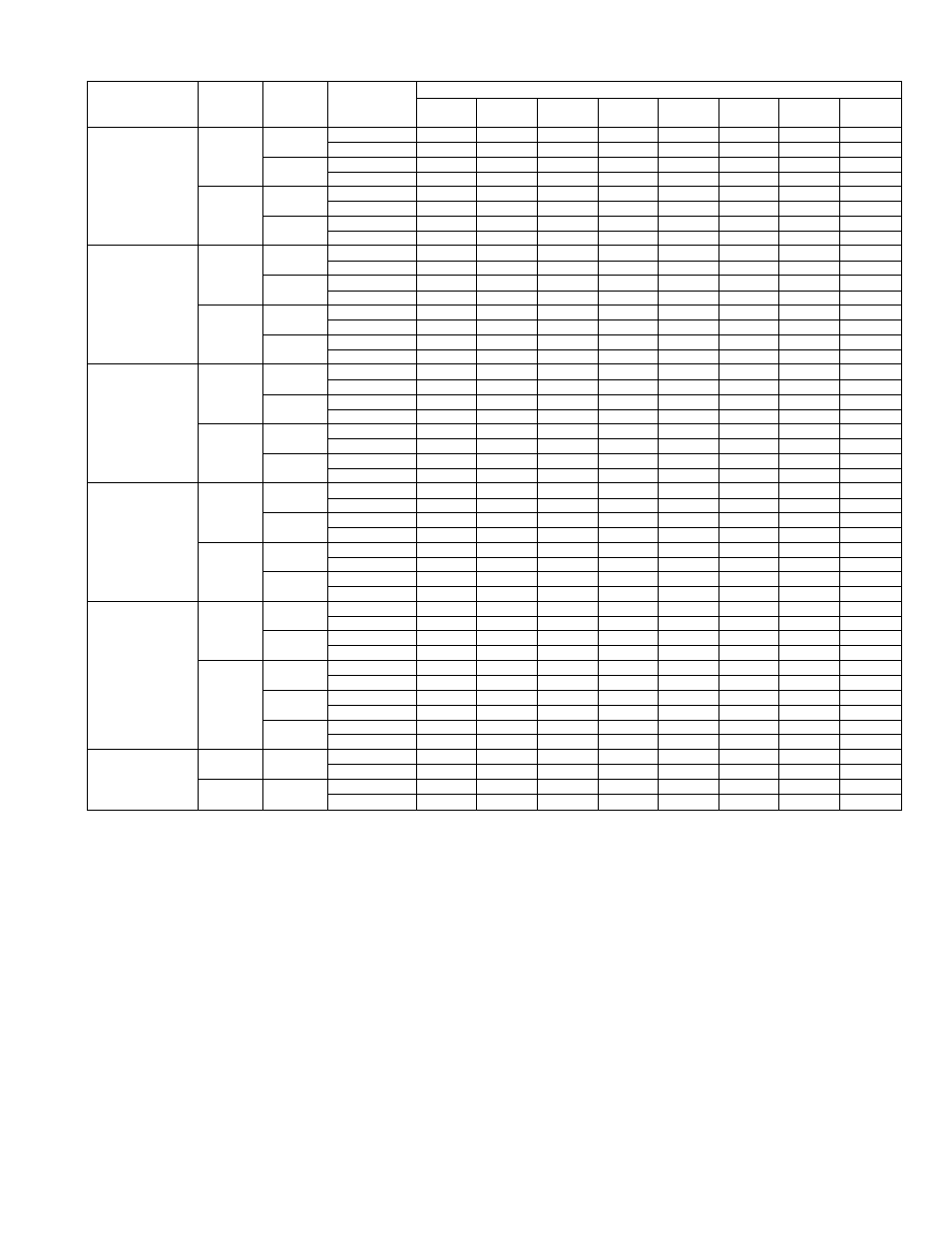

TABLE VI-AIR DELIVERY (FtVMin) AT INDICATED EXTERNAL STATIC PRESSURE & VOLTAGE*

Model

Blower

Motor

Speed

Opera

ting

Voltage

Applica-

tiont

External Static Pressure—Inches wc

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

542E024

Low

208

Heating

880

835

790

740

690

630

565

470

Cooling

850

810

770

725

675

615

550

465

230

Heating

965

925

880

835

780

720

655

575

Cooling

940

900

855

810

755

700

635

560

High

208

Heating

1015

970

920

870

815

750

685

605

Cooling

985

940

890

840

785

730

665

585

230

Heating

1070

1030

985

940

885

830

765

680

Cooling

1040

1000

955

910

855

800

735

660

542E030

Low

208

Heating

995

965

930

890

845

785

705

590

Cooling

980

945

910

865

820

760

680

560

230

Heating

1070

1050

1025

995

960

915

840

730

Cooling

1055

1030

1005

970

930

880

800

680

High

208

Heating

1165

■ 1145

1125

1095

1065

1020

955

845

Cooling

1150

1130

1105

1075

1035

980

900

770

230

Heating

1260

1245

1225

1200

1165

1125

1065

970

Cooling

1245

1225

1200

1170

1135

1080

1005

875

542E036

Low

208

Heating

1280

1235

1185

1135

1080

1020

955

875

Cooling

1225

1185

1140

1095

1040

985

920

850

230

Heating

1485

1435

1380

1325

1265

1200

1115

1025

Cooling

1400

1350

1300

1250

1190

1125

1050

970

High

208

Heating

1685

1630

1575

1510

1440

1360

1275

1160

Cooling

1565

1510

1455

1395

1325

1250

1160

1045

230

Heating

1850

1785

1720

1650

1575

1490

1395

1280

Cooling

1670

1615

1560

1495

1425

1345

1250

1100

542E042

Low

208

Heating

1400

1360

1315

M265v

1:205:

1130 :

1015-

_

Cooling

1370

1330

1280

1230

: 1165 : ■

1085

955

■

■

230

Heating

1655

1610

1560

1505

1435

1360

1270

: 1140

Cooling

1615

1565

1510

1450

1380

1305

1205

1050

High

208

Heating

1895

1840

1780

1715

1645

1570

1480

1365

Cooling

1825

1770

1710

1645

1570

1490

1395

1270

230

Heating

2125

2065

2005

1935

1860

1775

1685

1570

Cooling

2030

1970

1905

1835

1760

1675

1575

1440

542E048

Low

208

Heating

1690

1635

1575

1510

1440

1360

1270 :

1140

Cooling

1650

1595

1535

1475

1405

1325

1,230

1100

230

Heating

1905

1855

1800

1740

1675

1600

1510

:1370

Cooling

1860

1810

1755

1690

1625

1545

1445

1290

High

208

Heating

2005

1955

1900

1845

1780

1705

1625

1510

Cooling

1955

1905

1850

1790

1725

1650

1560

1430

230

Heating

2270

2195

2120

2040

1955

1870

1765

1650

Cooling

2180

2110

2040

1960

1880

1785

1685

1570

460

Heating

2070

2000

1925

1845

1760

1665

1560

1425

Cooling

2000

1930

1855

1775

1690

1595

1490

1355

542E060

(Single-

Low

230

Heating

2250

2205

2160

2110

2050

1990

1915

1830

Cooling

2180

2135

2085

2030

1970

1900

1815

1700

Phase

Units)

High

230

Heating

2700

2625

2550

2465

2380

2285

2175

2055

Cooling

2550

2475

2395

2315

2220

2120

2005

1860

* Deduct field-supplied air filter pressure drop & heater loss (when used) to obtain available external static pressure for ducting,

t Heating airflow values are with a dry coil. Cooling airflow values are with a wet coil.

NOTE:

Shaded portions of this table fall below 350ft^/min per 12,000 Btuh of rated cooling capacity. Indoor coil icing may ocur at airflows

below this point. Dashes are used in those areas of the table that fall beyond the capability of the indoor blower motor.

D. Unit Controls

All compressors have the following internal protection con

trols:

1. High-Pressure Relief VaZue—This valve opens when the

pressure differential between the low and high side

becomes excessive.

2. Compressor Ckterload—This internal overload interrupts

power to the compressor windings when either the cur

rent or internal temperature become excessive, and au

tomatically resets when the internal temperature drops

to a safe level. This overload may require up to 60

minutes (or longer) to reset; therefore if the internal

overload is suspected of being open, disconnect the

electrical power to the unit and check the circuit thru

the overload with an ohmmeter or continuity tester.

3. Low-Pressure Switch—This switch with automatic reset

interrupts the compressor control circuit when the

refrigerant high-side pressure becomes too low. It pro

tects the compressor from damage attributable to loss of

the refrigerant charge.

4. TimelTemperature Defrost System—The defrost control

system consists of a defrost timer, a defrost thermostat

switch, and a defrost relay. The system initiates defrost

cycle operation every 90 minutes if a coil icing condition

exists. See the defrost cycle sequence of operation in

Section VII.

5. Crankcase Heater—This device prevents overdilution of

compressor oil with refrigerant during shutdown

, periods, thereby extending the life of the compressor.

See the crankcase heater sequence of operation in Sec

tion VII.

6. Compressor Quick-Start Components—These components

are used with all single-phase units to improve com

pressor starting characteristics.

-

1 1

-