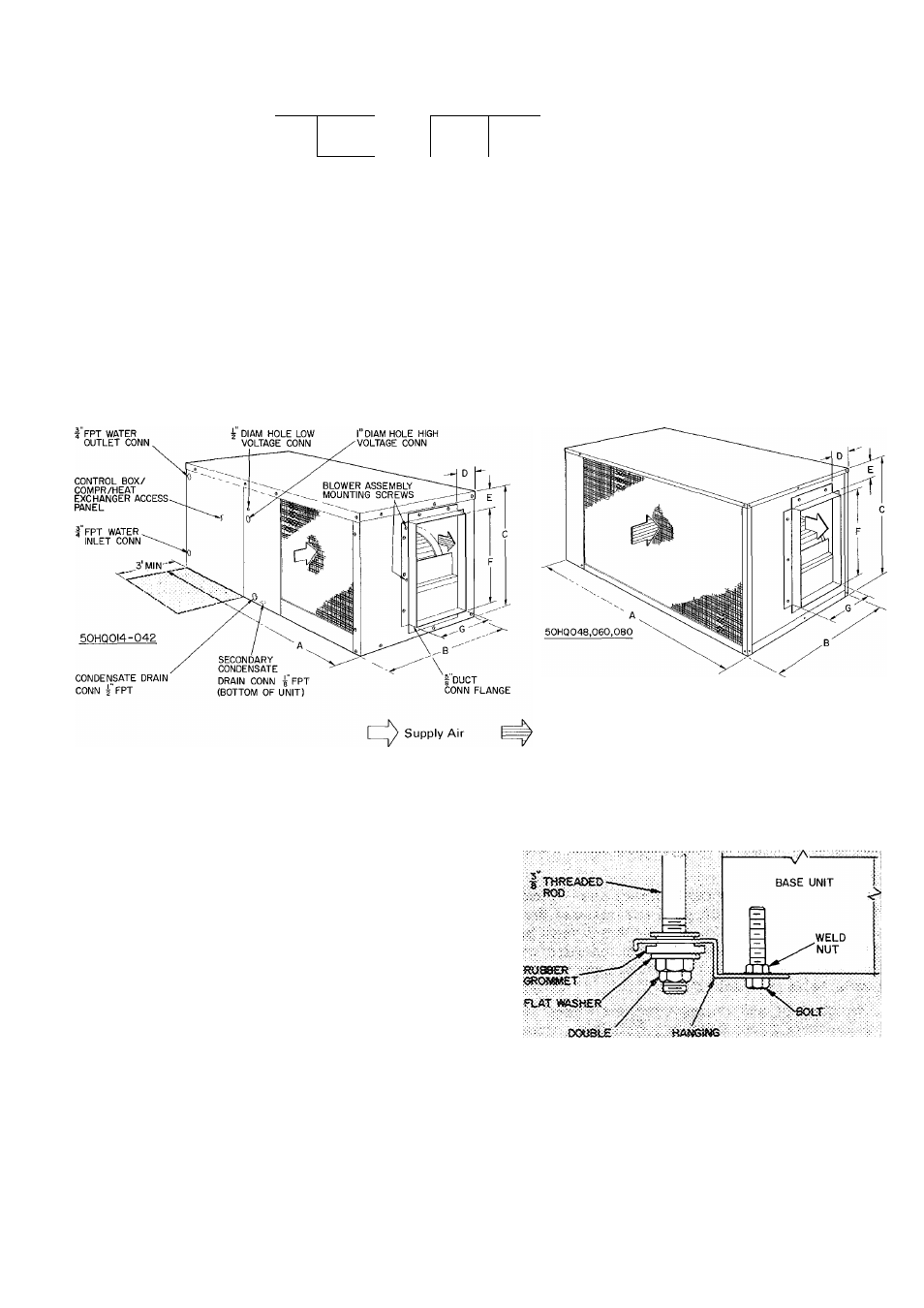

Installation data — 50hq (see fig. 2.), Fig. 2 — dimensions and connections — 50hq, Step 3 — make piping connections – Carrier 50HQ User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 2

MODEL

50HQ

ÒPÉR wt (ib) '

DIMENSIONS (ft-in )

A

B

C

D

E

SUPPLY DUCT CONN

(ft-in.)

F

G

ACCESSORY FILTER (1)

Size (in.)

^Includes 1-in accessory filter

Installation Data — 50HQ (See Fig. 2.)

042

014

018

022

027

033

185

195

210

220

230

250

3-10-3/8

1-10-3/16*

1-6

0- 3-7/16

0- 2-3/8

1- 1-3/8

0- 9-7/16

17 X 22-3/4

048

3Ò0

1-0-7/16

060

325

4-0

1

-

1 1

*

2-0-7/16

0-3-7/16

0- 2-3/8

1- 7-7/8

1-1-1/16

”360*

0-11-15/16

Replaceable Media

Return Air

Fig. 2 — Dimensions and Connections — 50HQ

Step 3 — Make Piping Connections

CONNECT WATER SUPPLY AND RETURN

LINES to water inlet and outlet pipe connections

shown in Fig. 4 and 5. Place plug in unused connec

tions. Use flexible hose for water line to reduce

possible vibration and improve unit serviceability.

Make sure hoses or pipes are suitable for system

water pressure and sized for proper flow rate.

CAUTION:

improper

heat

exchanger

water

flow due to piping, valving or improper pump

operation is hazardous to units.

For water flow and temperature data refer to

START-UP section, page 6.

CAUTION: Galvanized pipe or fiitiugs are not

recommended for use with these units due to

possible electrolysis.

«UT

8RACKET

Fig. 3 — Suspension Kit

Installation — 50HQ