Table 5 — chargemaster charging char)t – Carrier 50HQ User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

COMPRESSOR DISCHARGE PRESSURE®SERVICE PORT(PSIG)

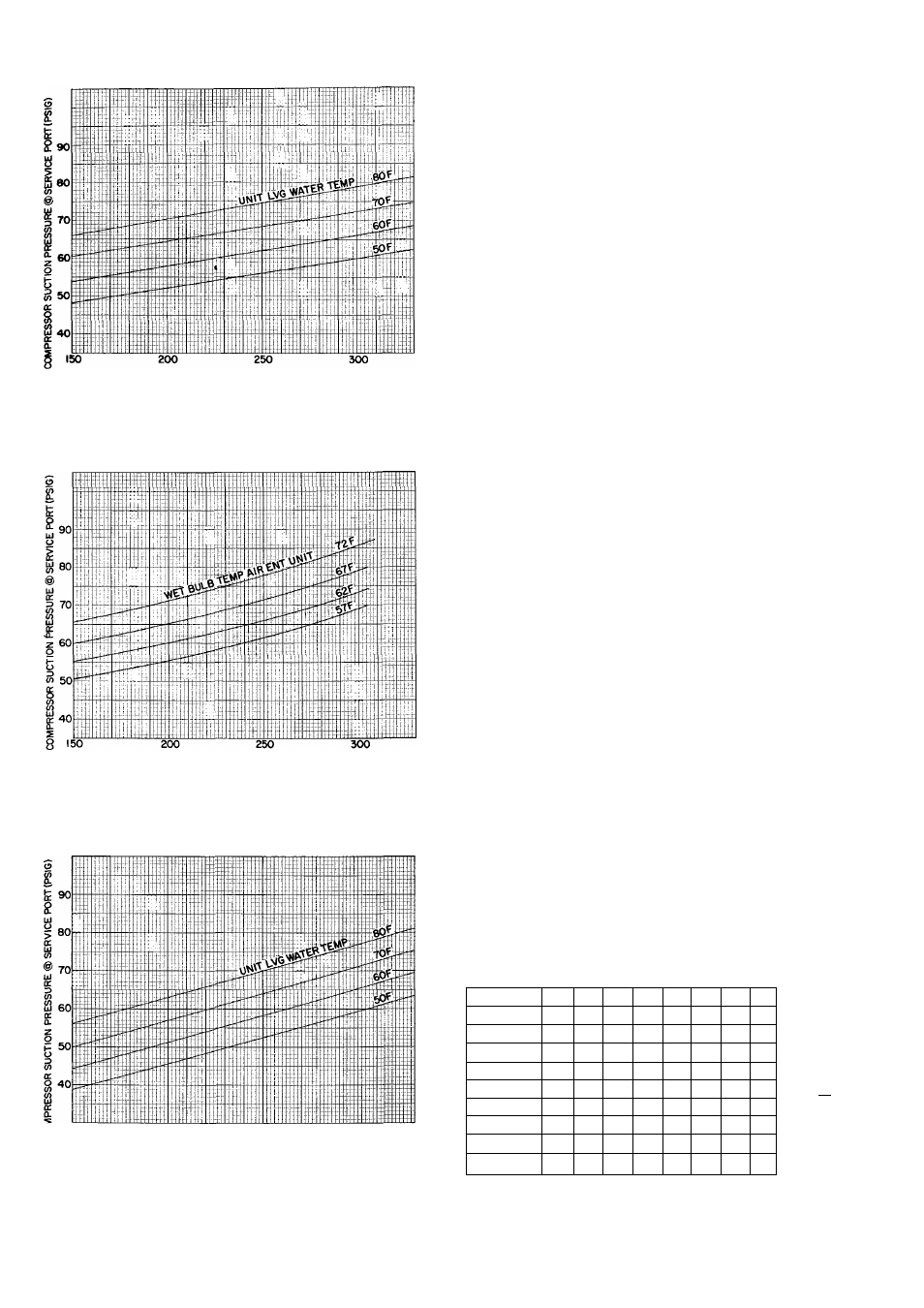

Fig. 18 — Heating Cycle Operation

Check Chart (R-22) — 50HQ,VQ033

COMPRESSOR DISCHARGE PRESSURE® SERVICE PORT(PSIG)

Fig. 19 — Cooling Cycle Charging Chart

(R-22) - 50HQ,VQ042

CHARGEMASTER® DEVICE OPERATION

Operate unit 10 minutes before using Charge-

master. Ensure unit indoor fan section access panel

is in place for proper Chargemaster operation.

1. Tape Chargemaster feeler bulb to unit suction

line. Insulate bulb. Ensure suction line is clean

for good contact with bulb.

2. Connect refrigerant drum to Chargemaster inlet

port with drum in position for vapor charging.

3. Connect Chargemaster outlet port (loosely) to

unit suction line Schrader valve.

4. Crack valves on refrigerant drum and Charge-

master to purge lines from drum to suction line

Schrader valve. After purging lines, close valve

on Chargemaster only. Tighten Chargemaster

connection at suction line Schrader valve.

5. Measure unit leaving water temperature.

6.

Read evaporator temperature at red needle

position on Chargemaster temperature gage and

suction

line

temperature

at

black

needle

position.

CAUITON: Do not read evaporator tempera

ture with Chargemaster valve open.

7. Enter 50HQ,VQ Chargemaster Charging Chart,

Table 5, at unit leaving water temperature (step

5) and evaporator temperature (step 6). (Do not

use standard charging chart on cover of Charge-

master.) Find the suction line temperature

required for correct system charge. If actual

suction line temperature (step 6) is higher than

table value, the system is undercharged. If suction

line temperature is lower than table value, the

system is overcharged.

Example: At leaving water temperature of 93 F

and evaporator temperature of 41 F, the system is

correctly charged at 50F ( ± 2 F ) suction line

temperature.

ISO

200

250

300

COMPRESSOR DISCHARGE PRESSURE @ SERVICE PORT(PSIG)

Fig. 20 — Heating Cycle Operation

Check Chart (R-22) — 50HQ,VQ042

Table 5 — Chargemaster Charging Char)t

UNIT

LEAVING

WATER

TEMP

(F)

30 33

36

EVAPORATOR TEMP (F)

44

47

53

56

Suction Line Temp (F)

69

46

49

5Ì

54

57

59

61

75

45

47

50

53

55

58

60

64

81

46

49

51

54

56

57

63

87

48

50

52

54

56

62

93

46

48

50

53

55

57

99

47

49

51

54

56

105

45

47

50

53

56

112

46

49

53

55

117

45

47

52

55

123

46

50

53

65

61

60

59

57

55

64

63

62

61

56”

*Saturated evaporator temperature which is the equivalent tem

perature of pressure taken at unit suction service valve

10