Troubleshooting chart (cont) – Carrier 50HQ User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

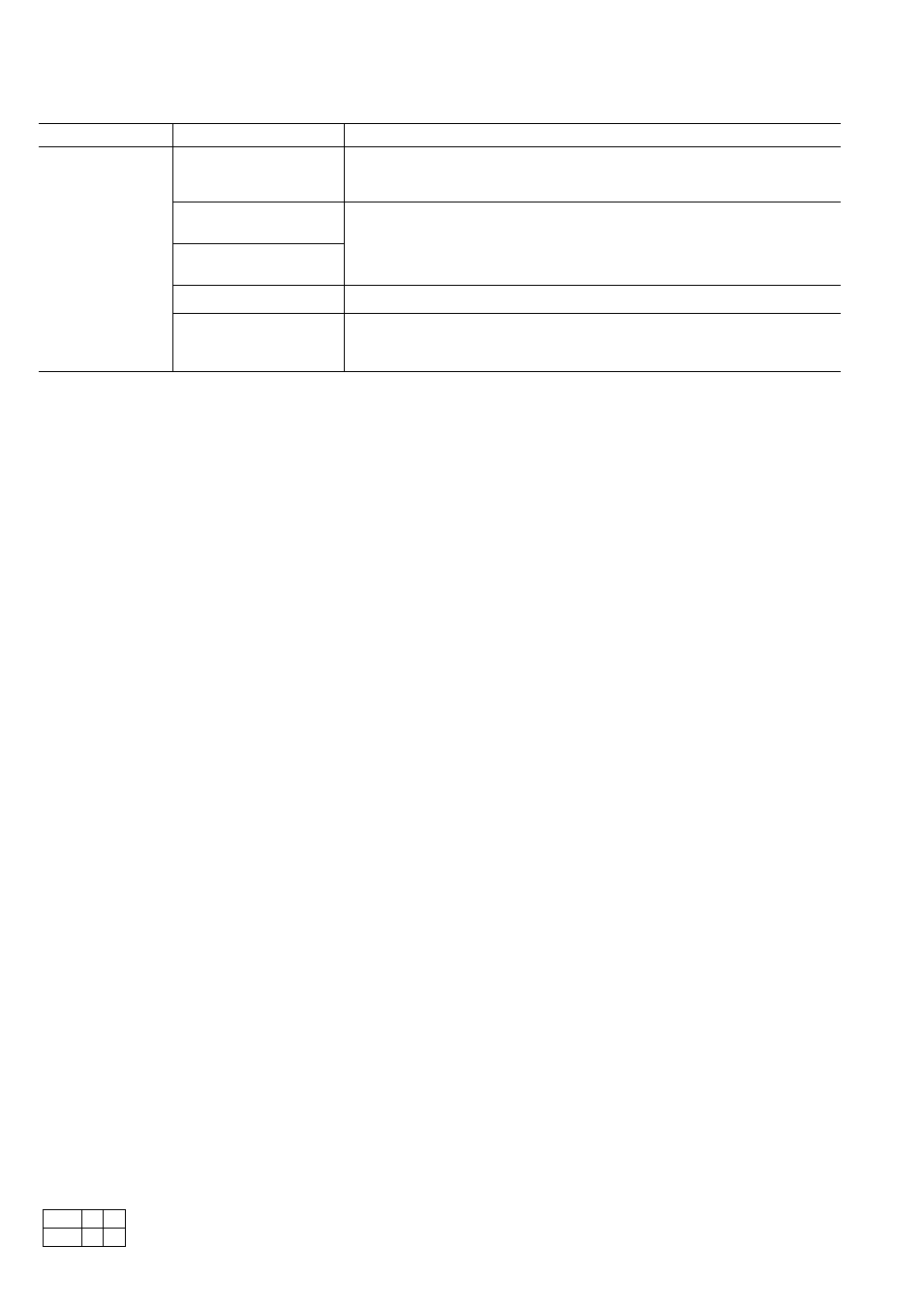

TROUBLESHOOTING CHART (cont)

PROBLEM

CAUSE

CORRECTION

NOISY OPERATION

Compressor

Make sure the compressor is not in direct contact with the base or sides of the cabinet

The hoid-down bolts used for shipping should be loosened so that the compressor is

floating free on its isolator mounts Excessive noise will occur if the compressor has a

broken valve or loose discharge tube. Replace the compressor

Blower and blower motor

Blower wheel hitting the casing Adjust for clearance and alignment Bent blower, check

and replace if damaged. Loose blower wheel on shaft Check and tighten Defective

bearings, check and replace

Contactors

A clattering or humming noise in the contactor could be due to control voltage less than

18 volts Check for low supply voltage, low transformer output or extra long runs of

thermostat wires If the contactor contacts or coil is defective, repair or replace

Rattles and vibrations

Check for loose screws, panels or internal components. Tighten and secure. Copper pip

ing could be hitting the metal surfaces Carefully readjust by bending slightly.

Airborne noises and

other sounds

Undersized ductwork will cause high airflow velocities and noisy operation

Excessive water thru the water-cooled heat exchanger will cause a rattling sound

Throttle back on the water flow ensuring adequate flow for good operation but elimi

nating the noise

#

For replacement items use Carrier Specified Parts.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book

1

4

Tab

5a

5a

Form 50HQ,VQ-1SI New

Printed in U S A

4-81

PC111

Catalog No 535-029