Carrier 38QN User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

To check system operation during heating cycle, use correct

Heating Cycle Check Chart (Fig. 7 through 14). These

charts indicate whether a correct relationship exists

between system operating pressure and air temperatures

entering indoor and outdoor units. If pressure and tempera

ture lines do not intersect on chart, system refrigerant

charge may not be correct or other system abnormalities

may exist. Do not use Heating Cycle Check Charts to adjust

refrigerant charge.

When recharging is necessary during heating season, weigh

in total charge as indicated on unit rating plate. Remove

any refrigerant remedning in system before recharging. If

the system has lost complete charge, evacuate and recharge

by weight. Service port connections are provided on liquid

and suction line service valves. For evacuation and recharg

ing, Dial-A-Charge charging cylinder is an accurate device

for recharging systems by weight.

To check and adjust charge during cooling season, use

Tables 4 and 5 and the following procedure:

1. Operate unit a minimum of 15 minutes before checking

charge.

2. Measure suction pressure by attaching a gage to suc

tion valve service port.

3. Measure suction line temperature by attaching a serv

ice thermometer to unit suction line near suction valve.

Insulate thermometer for accurate readings.

4. Measure outdoor coil inlet air dry-bulb temperature

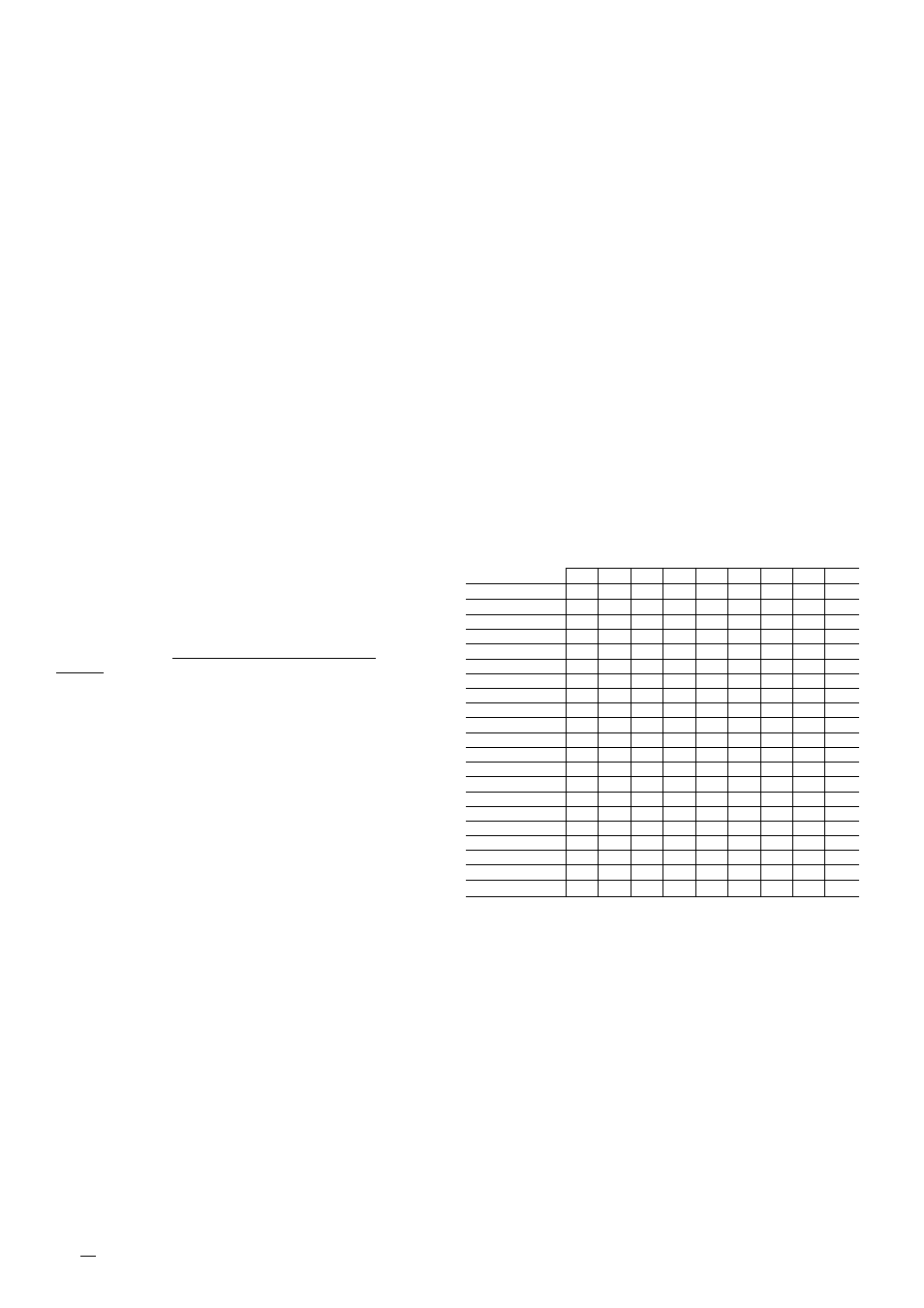

Table 4—Superheat Charging Table

(Superheat Entering Suction Service Valve)

OUTDOOR

TEMP(F)

55

60

65

70

75

80

85

90

95

100

105

110

115

50 52

12

10

INDOOR COIL ENTERING AIR (F) WB

54

14

12

10

56

17

15

13

10

58

20

18

16

13

60

23

21

19

16

12

62

26

24

21

19

15

12

64

29

27

24

21

18

15

11

66

32

30

27

24

21

18

15

13

10

68

35

33

30

27

24

21

19

16

14

12

70 72 74 76

37

35

33

30

28

25

22

20

18

15

13

11

40

38

36

33

31

28

26

24

22

20

17

15

42

40

38

36

34

31

30

27

25

23

22

20

8 14 18 23

45

43

41

39

37

35

33

31

29

27

26

25

-Do not attempt

refrigerant slugg

to charge system

ing may occur.

under these conditions or

with a second thermometer.

5. Measure indoor coü inlet air wet-bulb temperature with

a sling psychrometer.

6. Refer to Table 4. Find air temperature entering outdoor

coil and wet-bulb temperature entering indoor coil. At

this intersection, note the superheat.

7. Refer to Table 5. Find superheat temperature and suc

tion pressure, and note suction line temperature.

8. If unit has higher suction line temperature than

charted temperature, add refrigerant until charted tem

perature is reached.

9. If unit has lower suction line temperature them charted

temperature, bleed refrigerant until charted tempera

ture is reached.

10. If air temperature entering outdoor coU or pressure at

suction valve changes, charge to new suction line tem

perature indicated on chart.

11. This procedure is valid, independent of indoor air

quantity.

NOTE: For service data, refer to separate service manual

for Models 38EH,EN,ES,QH,QN,QS.

Table 5—Required Suction-Tube Temperature (F)

(Entering Suction Service Vaive)

TEIWP(F)

61.5 64.2 67.1 70.0 73.0 76.0 79.2 82.4 85.7

0

35

37

39

41

43

45

47

49

51

2

37

39

41

43

45

47

49

51

53

4

39

41

43

45

47

49

51

53

55

6

41

43

45

47

49

51

53

55

57

8

43

45

47

49

51

53

55

57

59

10

45

47

49

51

53

55

57

59

61

12

47

49

51

53

55

57

59

61

63

14

49

51

53

55

57

59

61

63

65

16

51

53

55

57

59

61

63

65

67

18

53

55

57

59

61

63

65

67

69

20

55

57

59

61

63

65

67

69

71

22

57

59

61

63

65

67

69

71

73

24

59

61

63

65

67

69

71

73

75

26

61

63

65

67

69

71

73

75

77

28

63

65

67

69

71

73

75

77

79

30

65

67

69

71

73

75

77

79

81

32

67

69

71

73

75

77

79

81

83

34

69

71

73

75

77

79

81

83

85

36

71

73

75

77

79

81

83

85

87

38

73

75

77

79

81

83

85

87

89

40

75

77

79

81

83

85

87

89

91

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

^ I

^

PC 101 Catalog No. 533-820

Printed in U.S.A.

Form 38QN-10SI

10-87 Pg 8

Tab 15a 15a

Replaces: 38QN-9SI