Fig. 4—line power connections, A caution, Fig- 5—determining amp draw – Carrier 38QN User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CONNECT GROUND LEAD AND POWER WIRING-

Connect ground lead to ground connection in control box for

safety. Then connect power wiring. See Fig. 4. Splice line

power leads to yellow and black pigtails. Use wire nuts and

tape at each connection. Connect unit wiring to copper

power wiring only.

CONNECT CONTROL POWER WIRING-Route 24-v

control wires through control wiring hole and channel and

connect leads to control wiring terminal board. See Fig. 1

and 6.

Use furnace or fan coil transformer as 24-v (40-va minimum)

supply for system as shown in Fig. 6, or use accessory

transformer.

l-PHASE

CONN. TO

'---GROUND LEAD-

-[H

groundin

'

g

lug

DISCONNECT

PER NEC

---- .---------

— YEL-------------------

I- PHASE

SPLICE CONNECTIONS

COND UNIT

----------------FIELD WIRING

--------------- FACTORY WIRING

3-PHASE

CONN. TO

DISCONNECT

PER NEC

--GROUND LEAD -

-UlGROUNDING LUG

3-PHASE UNIT

--------------Field Wiring

-------------- Factory Wiring

Fig. 4—Line Power Connections

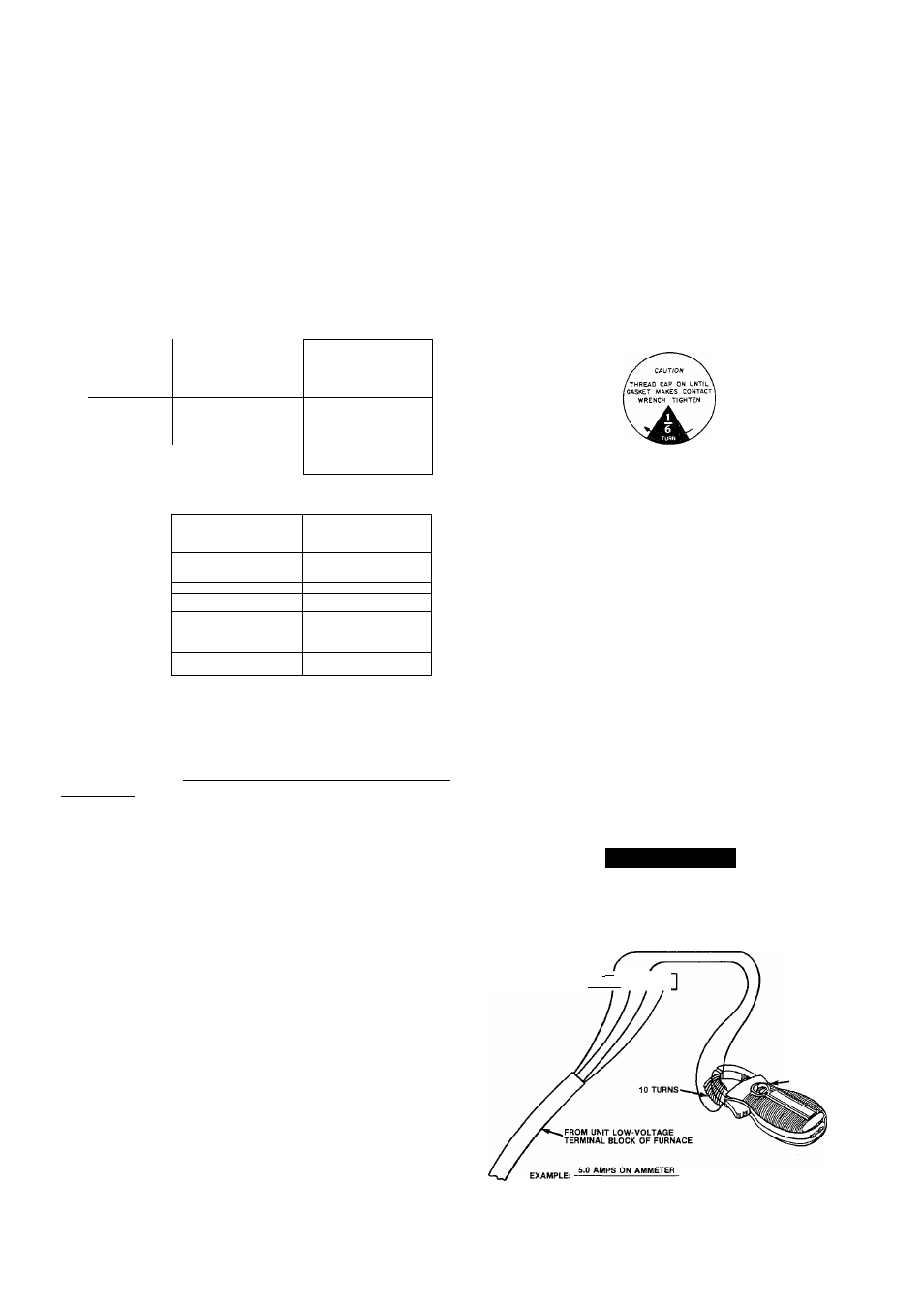

Step 5—Start-Up—

Heat Anticipator Settings for Room

Thermostat. To set the heat anticipator, move the heat

anticipator to the maximum setting. Determine which ter

minal powers the electric heater controls. With the heaters

energized, measure the amperage between the appropriate

W terminal and R and set the anticipator to the same valve.

Fig. 5 illustrates an easy method of obtaining the actual

amp draw.

Accessory Outdoor Thermostat

provides adjustable out

door control of accessory electric heater. This thermostat

makes contact when a drop in outdoor temperature occurs.

It energizes a stage of electric heat when the outdoor tem

perature setting is reached, provided the room thermostat

is on the second stage of heating. One outdoor thermostat is

recommended for each stage of electric heat after the first

stage. Set the outdoor thermostat(s) progressively lower for

each stage. Refer to heat load of building and unit capacity

to determine the correct outdoor thermostat settings.

The accessory supplemental heat relay is required when 2

outdoor thermostats are used. It is automatically energized

by the manually operated supplemental heat switch in the

indoor thermostat subbase. The thermostat locks out com

pressor and the relay bypasses the outdoor thermostats for

electric heater operation during heat pump shutdown. When

one outdoor thermostat is used, a supplemental heat relay is

not required. The supplemental heat switch in the indoor

thermostat subbase bypasses outdoor thermostat, locks out

compressor and activates electric heater.

MOUNT OUTDOOR THERMOSTAT in control box.

Attach brackets with short sheet metal screws to avoid con

tact with coH. Leave capUlary tube coiled in control com

partment making sure it is clear of aU electrical connections

and sharp metal edges.

MOUNT SUPPLEMENTAL HEAT RELAY in convenient

location on indoor unit. Attach with sheet metal screw.

To Start Unit

1. Energize crankcase heater a minimum of 24 hours

before starting unit. To energize heater only, set ther

mostat at OFF position and close electrical disconnect

to outdoor unit.

2. Backseat (open) liquid and suction line service valves.

4.

5.

6

.

7.

8

.

Unit is shipped with valve stem(s) frontseated, and

caps installed. Replace stem caps after system is

opened to refrigerant flow (backseated). Replace caps

finger tight and tighten additional % turn with wrench.

See sticker on valve cap.

Turn on main disconnect switch(es) to indoor and out

door units.

Set fan switch as desired (ON or AUTO).

Set thermostat dial at desired temperature.

Set selector switch at HEAT or COOL. Operate unit

for 15 minutes.

Check system refrigerant charge. See Refrigerant

Charging.

Motors and controls are designed to operate satisfactorily

in the voltage range shown in Table 3. If necessary to use

manifold gages for servicing, refer to Carrier Standard Serv

ice Techniques Manual, Chapter 1, Refrigerants, Pages 1-5,

Fig. 8 for bypass method of returning charge to system.

Removal of liquid line charging hose without following

these precautions could result in some loss of charge.

Refrigerant Charging

(Fig. 7 through 14)

A CAUTION

To prevent personal injury, wear safety glasses and

gloves when handling refrigerant. Do not overcharge

system. This can cause compressor failure.

THERMOSTAT

I

—^

A

TERMINALS"--- ® 0 ® ©

HOOK'AROUNO

VOLT/AMMETER

10 TURNS AROUND JAWS

0.5 AMPS FOR THERMOSTAT SETTING

Fig- 5—Determining Amp Draw