Carrier 38QN User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Sweat Connection—Use refrigerant grade tubing.

1. Remove locking nut, plug, rubber 0-ring and Schrader

core and cap from valve service port.

2. Cut tubing to correct length. Deburr and size as

necessary.

3. Insert tube in Compatible Fitting until it bottoms.

NOTE: Wrap top and bottom of service valves in wet

cloth to prevent damage by heat. Solder with low-

temperature (430 F) silver edloy solder.

4. Replace Schrader core and cap.

5. Evacuate or purge system with field-supplied

refrigerant.

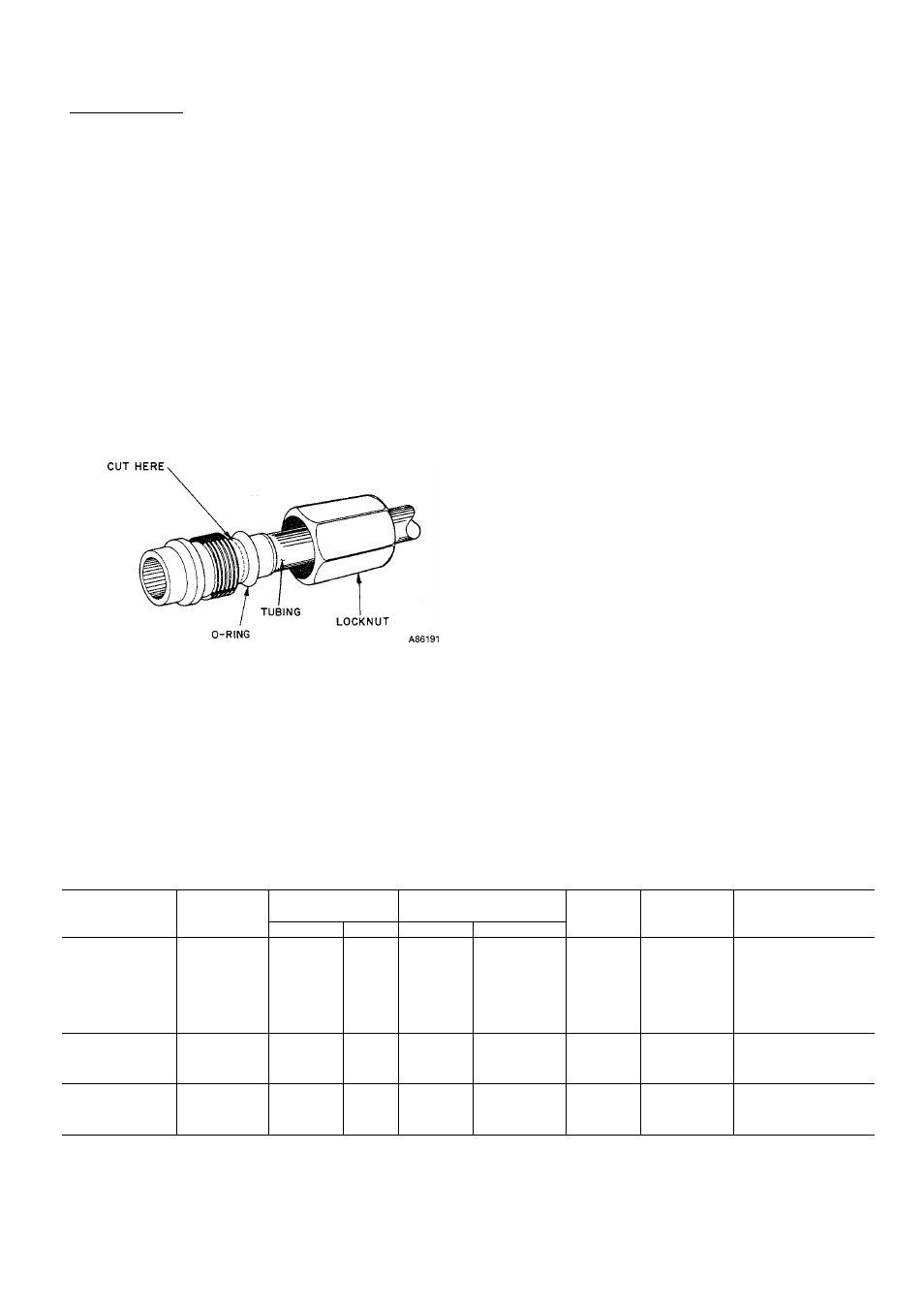

Compatible Fitting Repair

MECHANICAL CONNECTION-Frontseat unit service

valves. Relieve refrigerant pressure from tubing. Back off

locknut from Compatible Fitting onto tube. Cut fitting

between threads and 0-ring. See Fig. 3. Remove tubing sec

tion remaining in threaded portion of fitting. Discard

locknut.

COMPATIBLE FITTING

Clean, flux and insert new tube end into remaining portion

of Compatible Fitting. Wrap valve in wet rag to prevent

damaging factory-made joints. Heat and apply low-tempera

ture (430 F) solder.

SWEAT CONNECTION-Frontseat unit service valves.

Relieve refrigerant pressure from tubing. Clean and flux

around leak. Repair, using low-temperature (430 F) solder.

Evacuate or purge evaporator coil and tubing system. Add

refrigerant charge. See Refrigerant Charging.

Step 4—Make Electrical Connections—

Be sure field wir

ing comphes with local and national fire, safety and electri

cal codes, and voltage to system is within limits shown in

Table 3. Contact local power company for correction of

improper fine voltage.

NOTE: Operation of unit on improper line voltage consti

tutes abuse and could affect Carrier warranty. See Table 3.

Do not install unit in system where voltage may fluctuate

above or below permissible limits.

See Table 3 for recommended fuse sizes. When making elec

trical connections, provide clearance at unit for refrigerant

piping connections.

INSTALL BRANCH CIRCUIT DISCONNECT PER NEC

of adequate size to handle unit starting current. Locate dis

connect within sight from and readily accessible from unit,

per Section 440-14 of National Electrical Code (NEC).

ROUTE LINE POWER LEADS-Extend leads from dis

connect through power wiring hole provided (see Fig. 1) and

into unit splice area. Remove control box cover to gain

access to unit wiring.

Fig. 3—-Repair of Mechanicai Connection

Tabie 3—Eiectricai Data (60 Hz)

Three-phase availabie with 036-060 sizes

OUTDOOR

UNIT 38QN

V/PH

OPER VOLTS*

COMPR

FAN

FLA

MCA

MAX FUSEt OR

HACR TYPE

CKTBKRAMPS

Max

Min

LRA

RLA

015-32

35.0

7.2

0.7

9.7

15

018-33

49.0

10.5

0.7

13.8

20

024-32

53.0

13.2

2.1

18.6

30

030-34

208-230/1

253

197

70.0

17.6

1.9

24.1

40

036-31

86.7

18.9

0.9

24.5

40

042-31

108.0

21.8

2.6

29.9

50

048-31

110.0

27.3

1.9

36.0

60

060-31

142.0

33.0

2.1

43.4

60

036-51

65.0

11.5

0.9

15.3

25

042-51

208/230/3

254

187

80.0

13.3

2.5

19.1

30

048-51

92.0

14.7

1.9

20.2

30

060-51

130.0

21.4

2.1

28.9

, 45

036-61

32.8

5.1

1.6

8.0

15

042-61

460/3

506

414

35.0

7.2

1.6

10.6

15

048-61

46.0

7.0

1.6

10.4

15

060-61

65.0

9.6

1.6

13.9

20

FLA

—Full Load Amps

HACR—

Heating, Air Conditioning, Refrigeration

LRA

—Locked Rotor Amps

MCA

—Minimum Circuit Amps

RLA

—Rated Load Amps

NOTE: Control circuit is 24 v on all units and requires external power source.

♦Permissible limits of the voltage range at which unit will operate

satisfactorily.

tTime-delay fuse.