2 — 48kha.kla suggested rigging, Step 1, Installation rig and place unit – Carrier 48KHA User Manual

Page 2: Table 1 — perferjpiance data

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 1 — Perferjpiance Data

MODEL 48-

COOLING

CAPACITY

(Btuh)*

RATED

HEATING

INPUT

(Btuh)

OUTPUT

CAPACITY

(Btuh)

ARIt

SOUND

RATING

(Bels)

KLA118310BE

17,800

40,000

32,000

7.8

KLA124310BE

23,800

40,000

32,000

7 8

KHA024310BF

24,000

75,000

58,000

8.0

KLA130310BE

29,600

40,000

32,000

7 8

KHA030310BF

29,600

75,000

58,000

7.8

KLA136310BE

36,000

60,000

47,000

8 0

KLA036510CE

36,000

60,000

45,000

80

KLA036610CE

36,000

60,000

45,000

8 0

KHA136310BE

36,000

100,000

79,000

80

КНА036510СЕ

36,000

100,000

75,000

80

KHA036310BF

36,000

125,000

97,000

80

KHA036510CF

36,000

1 25,000

93,750

8.0

KLA142310BE

42,000

60,000

47,000

78

KLA042510CE

42,000

60,000

45,000

7 8

KHA042310BF

42,000

125,000

97,000

7 8

KHA042510CF

42,000

125,000

93,750

7.8

KLA148310BE

49,000

80,000

63,000

8 4t

KLA048510CE

49,000

80,000

60,000

8 41

KLA048610CE

49,000

80,000

60,000

8 41

KHA048310BF

49,000

125,000

97,000

8 41

KHA048510CF

49,000

125,000

93,750

8.41

KLA160310BE

60,000

100,0001:

79,000$

8 41

KHA060310BF

60,000

1 50,0001

11 6,0001

8 41

*Rated in accordance with U S Government DOE test procedures and/or

ARI Standard 210-81

tSound rating per ARI 270-84

^The capacity ratings of single-phase units are in accordance with U S

Government DOE test procedures and/or AGA certification require

ments For 3-phase units, the efficiency rating is a product thermal

efficiency

rating

determined

under

continuous

operating

conditions,

independent of any installed system

Units with number 1 in the 4th digit location of

model number in Table 1 meet California oxides of

nitrogen (NOx) maximum emission requirements.

Units are factory charged with R-22 refrigerant.

To install; connect gas supply, air ducts, high- and

low-voltage wiring and condensate drain, and install

a field-supplied air filter in the return-air ductwork.

All units can be connected into existing duct

systems that are properly sized and designed to

handle an airflow of350 to 450 cfm per each 12,000

Btuh of rated coaling capacity. See Table 8 for cool

ing and heating airflow requirements.

NOTE: When installing any accessory item, see

Installation Instructions packaged with accessory.

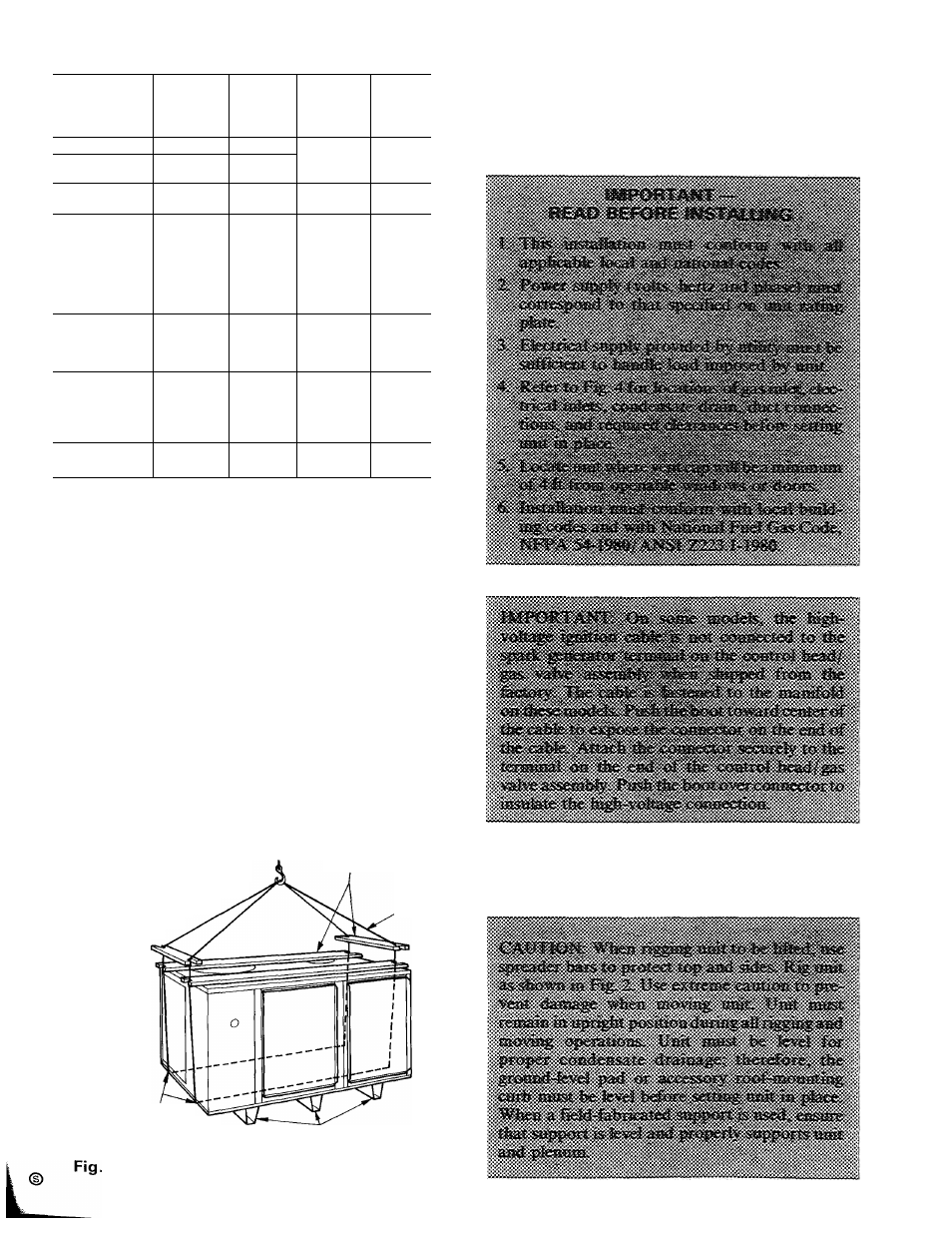

SPREADER BARS:

(2)2x4"xUNIT LENGTH PLUS lO" WITH

DEEP 90° NOTCHES EA(iH END

(2) ¿iiAxUNIT WIDTH WITH 1^

DEEP 90° NOTCHES

EACH END

SPREADER BARS

LOCATE CHAINS THROUGH

HOLES IN BASE

CHANNELS

CHAIN

TWO OR THREE BASE

CHANNELS ATTACHED TO

BOTTOM OF UNIT

2 — 48KHA.KLA Suggested Rigging

Step 1

INSTALLATION

Rig and Place Unit