Carrier 48KHA User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

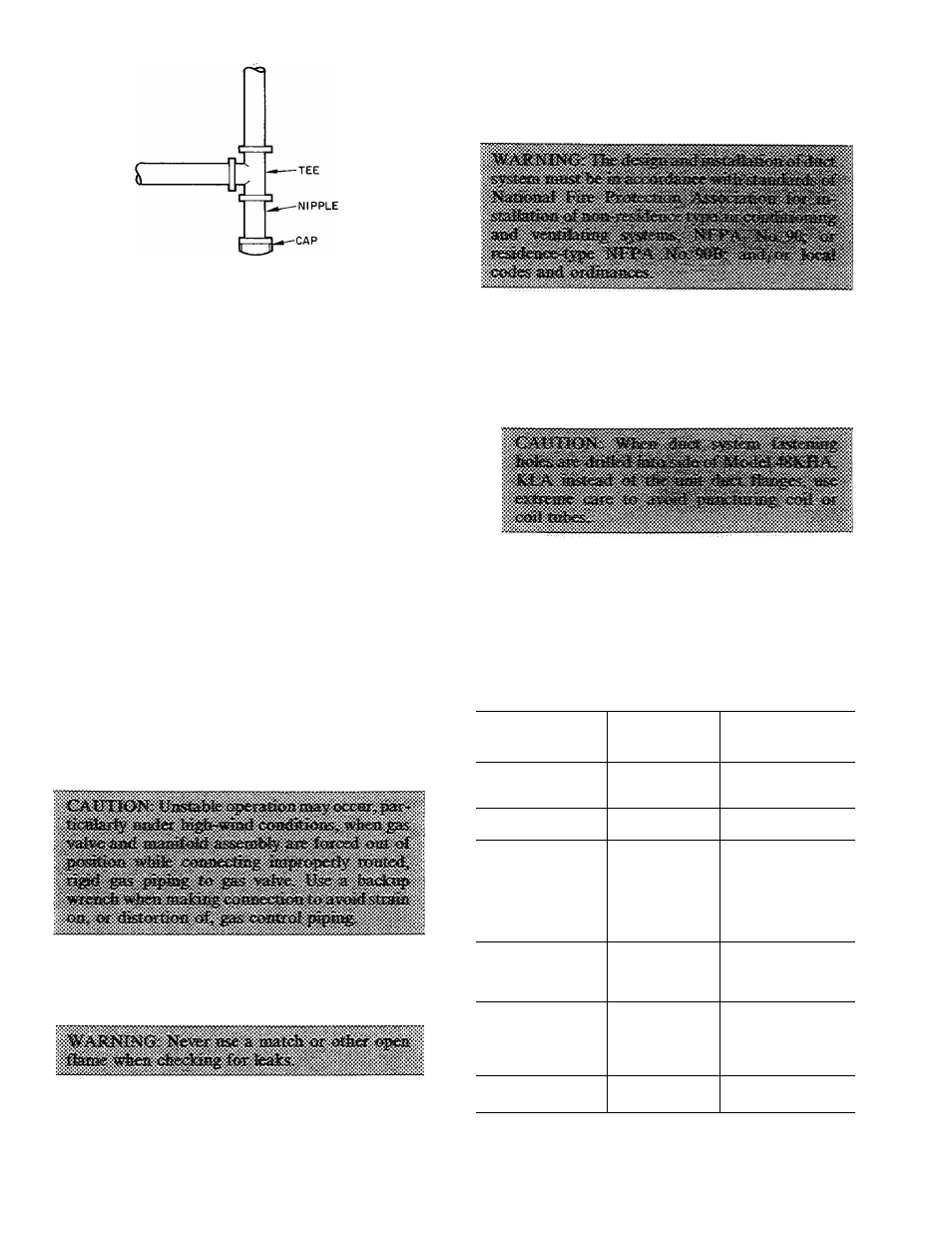

Fig. 7 — Sediment Trap

5. Install an accessible, external, manual shutoff

valve in gas supply pipe within 6 ft of heating

section.

NOTE: The unit manual shutoff valve has a

1/8-in. tapping on the inlet side of this shutoff

for measuring gas input pressure.

6. Install ground-joint union close to heating sec

tion between unit manual shutoff and external

manual main shutoff valve.

7. Pressure-test all gas piping in accordance with

local and national plumbing and gas codes before

eonnecting piping to unit.

NOTE: When pressure-testing the gas supply

system after the gas supply piping has been con

nected to the unit gas valve, the supply piping

must be disconnected from the gas valve during

any pressure testing of the piping systems at test

pressure in excess of 0.5 in. psig. When pressure

testing the gas supply piping system at test pres

sures equal to or less than 0.5 in. psig, the unit

heating section must be isolated from the gas

piping system by closing the external main

manual shutoff valve and slightly opening

ground-joint union.

8. Where permitted by local codes, use an approved

corrugated metal tubing gas connector between

rigid gas piping and unit manual shutoff.

L

9. Check for gas leaks at all field-installed and

factory-installed gas lines after all piping connec

tions have been completed. Use soap-and-water

solution (or method specified by local codes and/

or regulations).

Step 3 — Make Duct Connections

— Model

48KHA,KLA has duct flanges on the supply-and

return-air openings on side of unit. See Fig. 4 for

connection sizes and locations.

Adhere to the following requirements when se

lecting, sizing and installing duct system:

1. Select and size ductwork, supply-air registers and

return-air grilles according to ASHRAE recom

mendations and as presented in Carrier System

Design Manual, Part 2.

2. Use a flexible transition between rigid ductwork

and unit to prevent transmission of vibration.

The transition may be screwed or bolted to duct

flanges. Use suitable gaskets to ensure a weather-

tight and airtight seal.

Table 2 — Filter Sizes (Field Supplied),

(Sq In.)*

MODEL 48-

STANDARD

DISPOSABLE

TYPE

CLEANABLE OR

HIGH CAPACITY

TYPE

KLA118310BE

302

202

KHA024310BF

454

303

KLA124310BE

384

257

KHA030310BF

480

320

KLA130310BE

480

320

KHA036310BF

694

462

KHA036510CE

576

384

KHA036510CF

694

462 .

KHA136310BE

576

384 >

KLA036510CE

576

384

KLA036610CE

576

384

KLA136310BE

576

384

KHA042310BF

694

462

KHA042510CF

694

462

KLA042510CE

672

448

KLA142310BE

672

448

KHA048310BF

768

512

KHA048510CF

768

512

KLA048510CE

768

512

KLA048610CE

768

512

KLA148310BE

768

512

KHA060310BF

960

640

KLA160310BE

960

640

*Required air filter areas shown are based on the ARI-rated cooling

airflow or the heating airflow at a velocity of 300 fpm depending

on whichever value is larger Air filter pressure drop should not

exceed 0 08 in wg