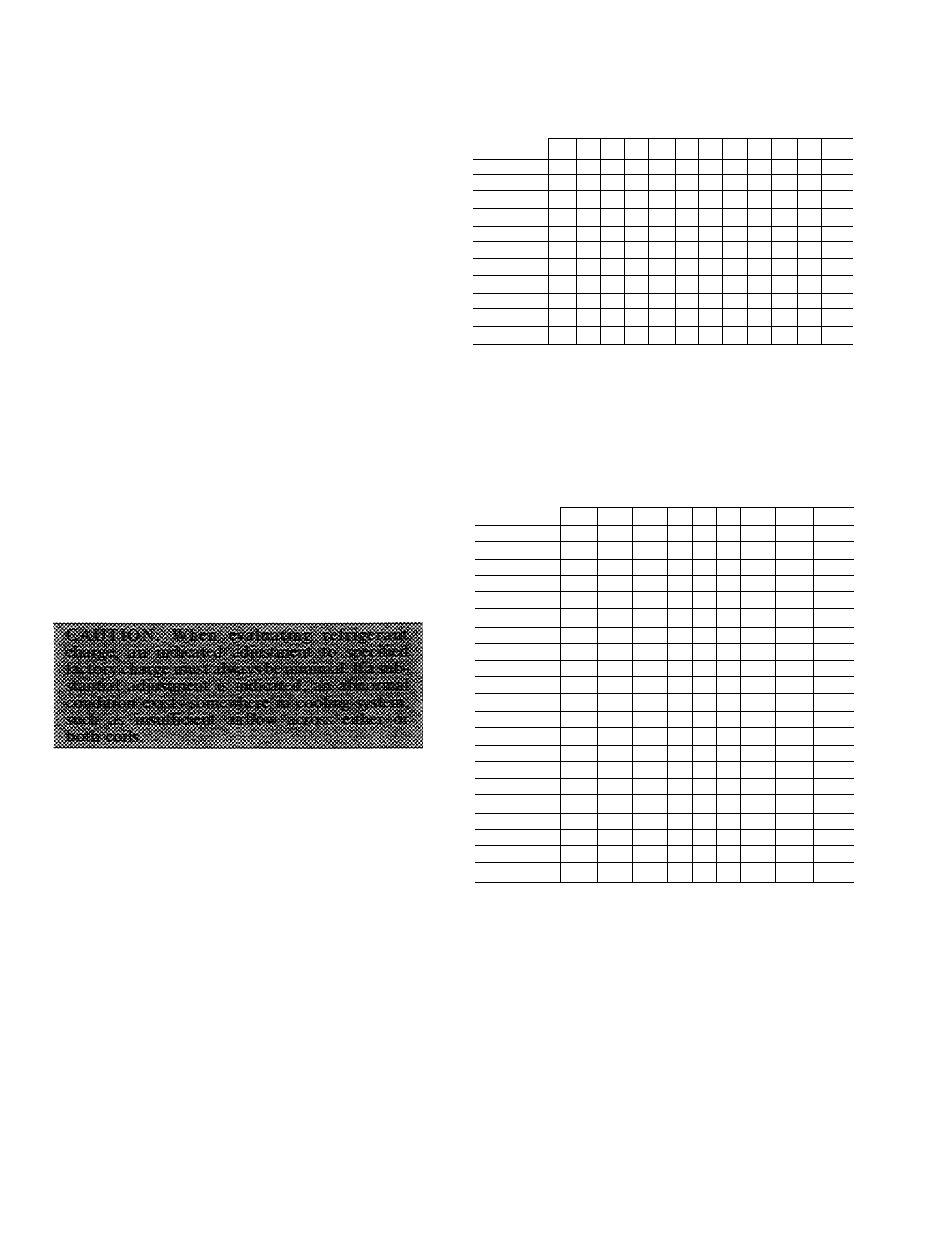

Table 7 — refrigerant charging label – Carrier 48KHA User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CHECKING AND ADJUSTING REFRIGER

ANT CHARGE — Refrigerant system is fully

charged with R-22 refrigerant, tested and factory

sealed. For most applications, factory charge is the

correct amount for best performance; however, this

charge may require a slight adjustment to attain

rated performance.

NOTE: Adjustment of refrigerant charge is not re

quired unless unit is suspected of not having proper

R-22 charge. For all applications, correct R-22

charge for best performance is charge that results in

a suction gas superheat of 5 F at compressor inlet

when unit is operating at ARI rating conditions of

95 F db outdoor and 80 F db/67 F wb indoor.

A superheat charging label is attached to outside

of compressor access door. Label includes a Field

Superheat Charging Table and a Required Suction-

Tube (F) temperature chart.

Table 7 is intended for use when minor unit charge

adjustments are required. For large adjustments,

evacuate unit and weigh in charge according to unit

rating plate. Use Table 7 to approximate charge if

ARI rating conditions cannot be obtained. Refer to

required airflow rates in Table 8. Charge unit with

outdoor fan operating only at high speed.

An

accurate

superheat-,

thermocouple-,

or

thermistor-type thermometer, a sling psychrometer

and a gage manifold are required when using super

heat charging method for evaluating unit charge.

Do not use mercury or small dial-type thermometers

because they are not adequate for this type of

measurement.

Proceed as follows:

1. Remove caps from low- and high-pressure serv

ice fittings. See Fig. 4 for location of entrance

for refrigerant pressure gage hoses.

2. Using hoses with valve core depressors, attach

low- and high-pressure gage hoses to low- and

high-pressure service fittings, respeetively.

3. Start unit in cooling mode and let unit run until

system pressures stabilize.

4. Measure and record the following:

a. Outdoor ambient-air temperature (F db).

b. Evaporator inlet-air temperature (F wb).

c.

Suction-tube temperature (F) at low-side

service fitting.

d. Suction (low-side) pressure (psig).

Using Field Superheat Charging Table, compare

outdoor-air temperature (F db) with evaporator

inlet-air temperature (F wb) to determine desired

system operating superheat temperature.

Using Required Suction-Tube (F) table, com

pare desired superheat temperature with suction

Oow-side) operating pressure (psig) to determine

proper suction tube temperature.

5.

6

.

Table 7 — Refrigerant Charging Label

DESIRED SUPERHEAT TEMPERATURE (F)

(Measured @ Low-Side Service Port)

OUTDOOR

EVAPORATOR AIR INLET EWB (F)

EDB (F)

54

56

58

60

62

64

66

68

70

72

74

76

65

10

13

16

19

21

24

27

30

33

36

38

41

70

7

10

13

16

19

21

24

27

30

33

36

39

75

—

6

9

12

15

18

21

24

28

31

34

37

80

—

—

5

8

12

15

18

21

25

28

31

35

85

—

—

__

8

11

15

19

22

26

30

33

90

—

—

—

5

9

13

16

20

24

27

31

95

6

10

14

18

22

25

29

100

—

—

—

—

__

8

12

15

20

23

27

105

5

9

13

17

22

26

110

—

—

—

6

11

15

,

20

25

115

-

-

-

—

-

—

—

8

14

18

23

NOTES:

1 DashedAreas: Do not attempttocharge system undertheseconditionsor

refrigerant slugging may occur

2 Add charge if actual superheat temperature is higher than chart value

and remove if lower Allow ±3F for tolerance

REQUIRED SUCTION-TUBE TEMPERATURE (F) vs.

DESIRED SUPERHEAT TEMPERATURE (F)

(Measured @ Low-Side Service Port)

DESIRED

SUPERHEAT

SUCTION OR LOW-SIDE PRESSURE (Psig)

AT SERVICE PORT

TEMP (F)

61.5

64.2

67.1

70

73

76

79.2

82.4

85.7

0

35

37

39

41

43

45

47

49

51

2

37

39

41

43

45

47

49

51

53

4

39

41

43

45

47

49

51

53

55

6

41

43

45

47

49

51

53

55

57

8

43

45

47

49

51

53

55

57

59

10

45

47

49

51

53

55

57

59

61

12

47

49

51

53

55

57

59

61

63

14

49

51

53

55

57

59

61

63

65

16

51

53

55

57

59

61

63

65

67

18

53

55

57

59

61

63

65

67

69

20

55

57

59

61

63

65

67

69

71

22

57

59

61

63

65

67

69

71

73

24

59

61

63

65

67

69

71

73

75

26

61

63

65

67

69

71

73

75

77

28

63

65

67

69

71

73

75

77

79

30

65

67

69

71

73

75

77

79

81

32

67

69

71

73

75

77

79

81

83

34

69

71

73

75

77

79

81

83

85

36

71

73

75

77

79

81

83

85

87

38

73

75

77

79

81

83

85

87

89

40

75

77

79

81

83

85

87

89

91

NOTE: Measure suction-tube temperature with an accurate superheat

thermocouple, or thermistor-type thermometer

7. Compare actual suction-tube temperature with

proper suction tube temperature. Using a toler

ance of ±3 F, add refrigerant if actual tempera

ture is more than 3 F higher than proper suction

tube temperature, or remove refrigerant if actual

temperature is more than 3 F lower than required

suction-tube temperature.

NOTE: If the problem causing inaccurate readings is

a refrigerant leak, see Unit Preparation, Refrig

erant Leaks section of these instructions.

16