Step 2 — make gas piping connections — a – Carrier 48KHA User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Step 2 — Make Gas Piping Connections

— A

manual shutoff valve is shipped loose in the burner

compartment or blower compartment. Connect one

end of a field-supplied 1/2-in. straight nipple to the

gas valve inlet. Connect the other end of the nipple

to the manual shutoff valve as shown in Fig. 6. The

gas supply pipe enters unit through access hole pro

vided. See Fig. 4 for location. The gas connection to

unit is made to the 1/2-in. FPT gas inlet on manual

shutoff. See Fig. 6 for inlet location.

Install a separate gas supply line that runs directly

from meter to heating section. Do not use cast-iron

pipe. Check local utility for recommendations con

cerning existing lines. Choose a supply pipe that is

large enough to keep pressure loss as low as prac

tical. Never use pipe smaller than the 112-in. FPT

gas inlet on unit manual shutoff.

When installing gas supply line, observe local

codes pertaining to gas pipe installations. Refer to

National Fuel Gas Code, NFPA 54-1980/ANSI

Z223.1-1980 in absence of local building codes.

Adhere to following pertinent recommendations:

1

2

3

4

5

6

7

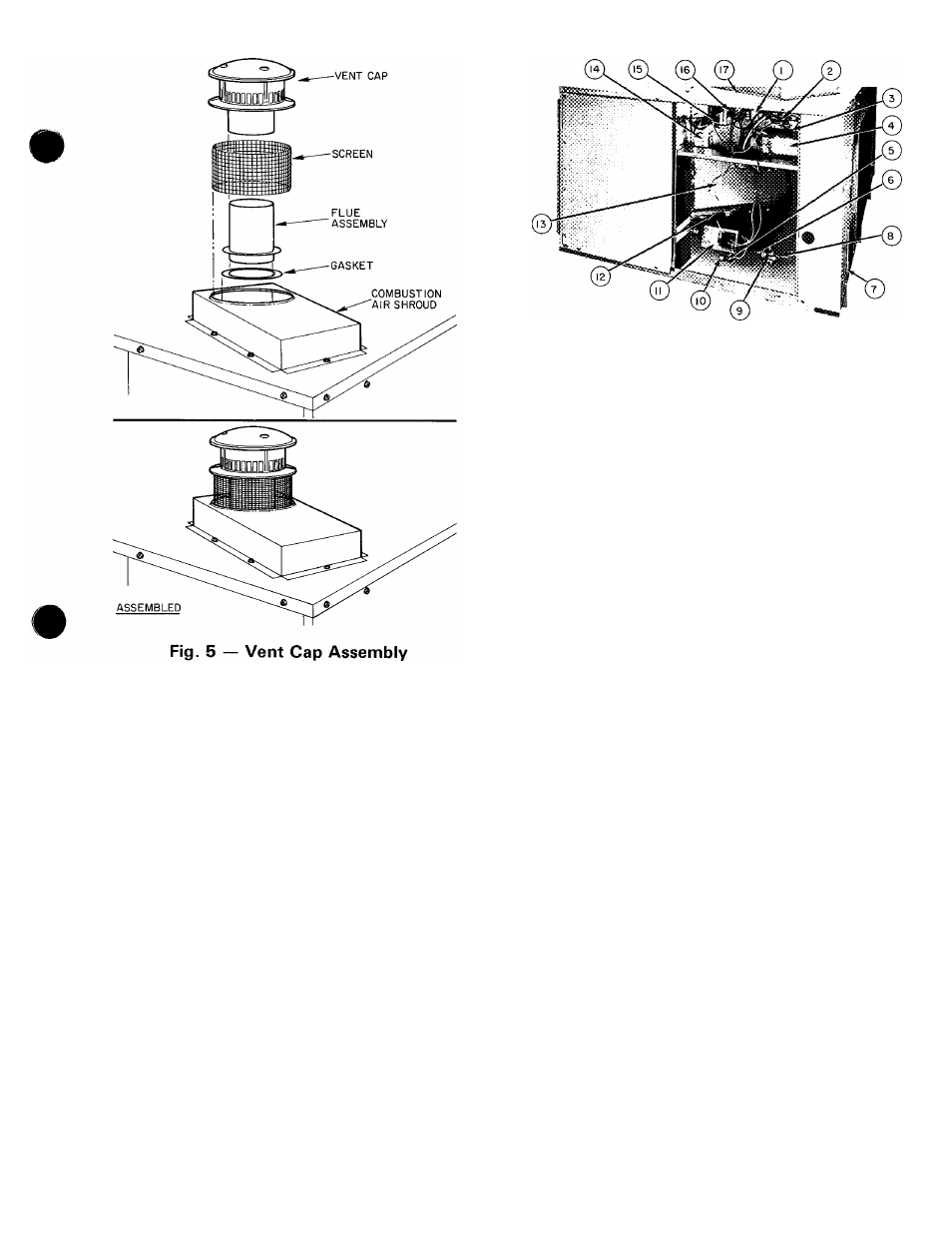

Control Transformer

9

Compressor Contactor

10

Ground Lug

Dual Run Capacitor

11

(for compressor and

12

condenser fan motor)

13

Gas Valve

1/2-in Nipple

14

Gas Pipe

Entrance Hole

15

Gas Inlet

16

Pressure Tap

17

Manual Shutoff

Regulator, Adjustment

Cover Screw

Electronic Control Head

Secondary-Air Shield

Low-Voltage Pigtail

Leads

Blower Motor Run

Capacitor

Heating Relay

Cooling Relay

Combustion Air Shroud

Fig. 6 — Model 48KLA036 — Side View

(Partial) with Access Doors Removed

1. Avoid low spots in long runs of pipe. Grade all

pipe I /4 in. in every 15 ft to prevent traps. Grade

all horizontal runs downward to risers. Use risers

to connect to heating section and to meter.

2. Protect all segments of piping system against

physical and thermal damage. Support all piping

with appropriate hangers, etc. Use a minimum of

one hanger in every 6 feet. For pipe sizes larger

than 1 / 2 in., follow recommendations of national

codes.

3. Apply joint compound (pipe dope) sparingly and

only to male threads of joint when making pipe

connections. Use only pipe dope that is resistant

to action of liquefied petroleum gases as speci

fied by local and/or national codes. Never use

pipe thread tape.

4. Install a sediment trap in riser leading to the heat

ing section. See Fig. 7. This drip leg functions as a

trap for dirt and condensate. Install trap where

condensate cannot freeze. Install this sediment

trap by connecting a piping tee to riser leading to

heating section, so that straight-through section

of tee is vertical. Then, connect capped nipple

into lower end of tee. Extend capped nipple

below level of gas controls.