Carrier 50HQ User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 4 — Service Data

UNIT 50HQ.VQ

014

018

022

027

033

042

048

060

080

R-22 CHG (Ib-oz)»

1-8

1-13

2-2

2-6

2-6

2-14

4-3

5-3

6-8

Refrig Control

Capillary Tube

FAN

Centrifugal — Direct Drive

Diameter (in. Nom)

10

10

10

10

10

11

10

10

12

Width (in. Nom)

7

7

7

7

7

7

8

10

9

Range Cfm

400-600

500-700

600-800

750-1000

950-1200

1225-1575

1400-1800

1750-2250

2300-3000

Motor Hp

1/8

1/8

1/6

1/6

1/4

1/3

1/2

3/4

1

Motor Rpm

1075 Nominal

1000

(3-speed)

HEAT EXCHANGER

WATER FLOW RATE

2 5-5

3-6

4-8

4 5-9

5-10

6-12

8-16

11-21

14-28

(Gpm)

‘Factory refrigerant charge

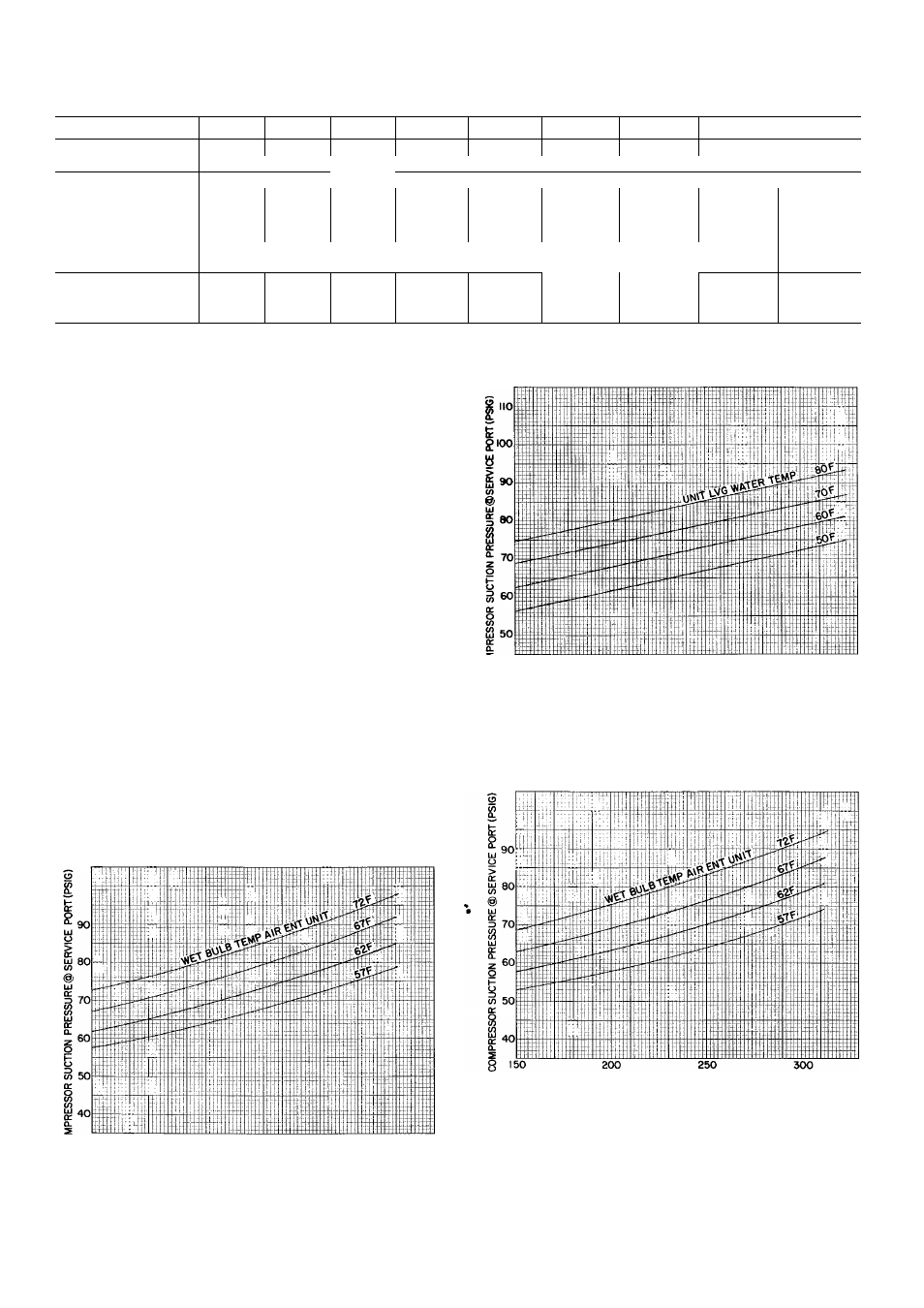

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before

checking

charge,

and

after

each

charge

adjustment.

2. Measure suction pressure by attaching a gage to

unit suction service port (Schrader Fitting).

3. Measure discharge pressure by attaching a gage

to unit discharge service port (Schrader Fitting).

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering unit.

5. Refer to correct Charging Chart. Locate on

curves where unit discharge pressure line and

indoor air wet-bulb temperature line intersect.

6. From intersect point, project horizontally left to

chart suction pressure line. Compare chart

suction pressure to unit suction pressure (step 2).

7. If unit suction pressure is lower than chart pres

sure, add refrigerant to unit until chart pressure

is reached. If unit suction pressure is higher than

chart pressure, remove refrigerant until chart

pressure is reached.

ISO

200

250

300

COMPRESSOR DISCHARGE PRESSURE ® SERVICE PORT(PSIG)

Fig. 9 — Cooling Cycle Charging Chart

(R-22) — 50HQ,VQ014

ISO

200

250

300

COMPRESSOR DISCHARGE PRESSURE @ SERVICE PORT (PSIG)

Fig. 10 — Heating Cycle Operation

Check Chart (R-22) — 50HQ.VQ014

COMPRESSOR DISCHARGE PRESSURE @ SERVICE PORT (PSIG)

Fig. 11 — Cooling Cycle Charging Chart

(R-22) — 50HQ.VQ018