Compressor removal – Carrier 50HQ User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CHARGEMASTER® DEVICE OPERATION —

Operate unit 10 minutes before using Charge-

master. Ensure unit indoor fan section access panel

is in place for proper Chargemaster operation.

1. Tape Chargemaster feeler bulb to unit suction

line. Insulate bulb. Ensure suction line is clean

for good contact with bulb.

2. Connect refrigerant drum to Chargemaster inlet

port with drum in position for vapor charging.

3. Connect Chargemaster outlet port (loosely) to

unit suction line Schrader valve.

4. Crack valves on refrigerant drum and Charge-

master to purge lines from drum to suction line

Schrader valve. After purging lines, close valve

on Chargemaster only. Tighten Chargemaster

connection at suction line Schrader valve.

5. Measure unit leaving water temperature.

6.

Read evaporator temperature at red needle

position on Chargemaster temperature gage and

suction

line

temperature

at

black

needle

position.

CAUTiON: Do not read evaporator tempera

ture with Chargemaster valve open.

7. Enter 50HQ,VQ Chargemaster Charging Chart,

Table 5, at unit leaving water temperature (step

5) and evaporator temperature (step 6). (Do not

use standard charging chart on cover of Charge-

master.) Eind the suction line temperature

required for correct system charge. If actual

suction line temperature (step 6) is higher than

table value, the system is undercharged. If suc

tion line temperature is lower than table value,

the system is overcharged.

Example: At leaving water temperature of 93 F

and evaporator temperature of 41 F, the system

is correctly charged at 50 F ( ± 2 F ) suction line

temperature.

8. Add charge by slowly opening Chargemaster

valve. If necessary, reduce charge by bleeding at

liquid line Schrader valve. Check outdoor air

and evaporator temperature during procedure.

If they change, refer back to Chargemaster

Charging Chart for new value.

Correct use of Chargemaster ensures that an

optimum refrigerant charge is in system when

conditions and system components are normal.

However, the Chargemaster does not solve or fix

system abnormalities. It indicates correct charge

for condition of system. It does not make correc

tions for dirty filters, slow fans, or other abnormal

conditions. This charging device ensures that a

correct relationship exists between leaving water

temperature, evaporator temperature, and suction

line temperature on a specific system.

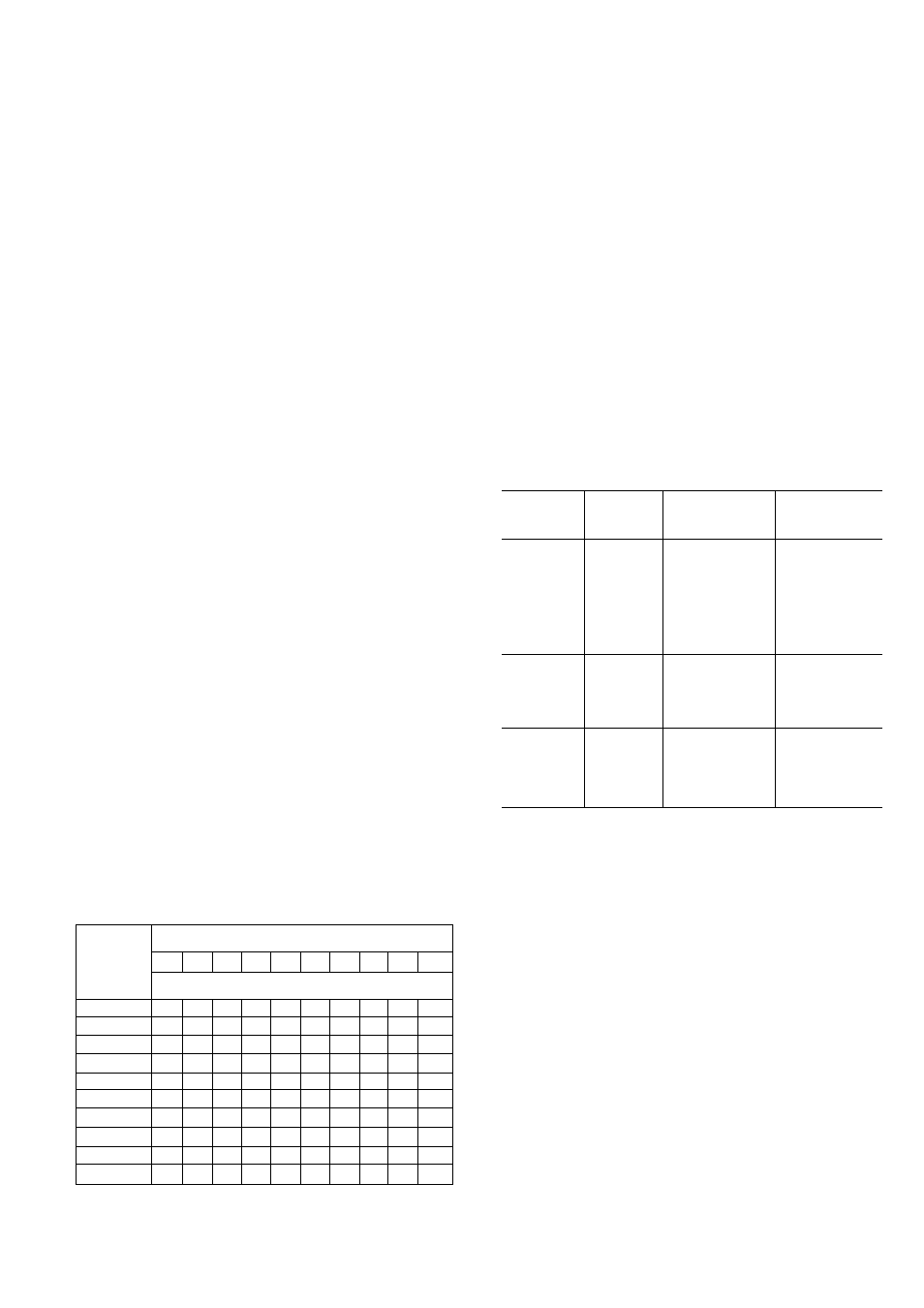

Table 6 — Compressor Data

UNIT

50HQ,VQ

V/PH

PRODUCTION

COMPRESSOR

OIL

RECHARGE

(oz)

014

AJ55Ì3F

24

018

AB5519F

32

022

MD2023FE

42

027

033

208/230-1

MD2423FE

MD3423FE

42

42

042

MD4023FE

42

048

PC4616AD

72

060

PC6416AG

72

033

MF3423FE

42

042

MF4023FE

42

048

208/230-3

PY4616AD

72

060

PY6416AF

72

080

PY7716AF

72

033

MH3423FE

42

042

MH4023FE

42

048

460/3

PH4616AD

72

060

PH6416AF

72

080

PH7716AF

72

Table 5 — Chargemaster Charging Chart

UNIT

LEAVING

WATER

TEMP

(F)

EVAPORATOR TEMP (F)*

30

33

36

39

41

44

47

50

53

56

Suction Line Temp (F)

69

46

49

51

54

57

59

61

75

45

47

50

53

55

58

60

64

81

46

49

51

54

56

57

63

87

48

50

52

54

56

62

65

93

46

48

50

53

55

57

61

99

47

49

51

54

56

61

64

105

45

47

50

53

56

60

63

112

46

49

53

55

59

62

117

45

47

52

55

57

61

123

46

50

53

55

56

Compressor Removal

See Table 6 for compressor information and

Fig. 7 for component location. Follow safety codes,

and wear safety glasses and work gloves. Have

quenching cloth available (step 7).

’Saturated evaporator temperature which is the equivalent tem

perature of pressure taken at unit suction service valve

CAUTION: Copper tubing and aluminum fins

are used in unit coils. Do not overbeat or place

excessive strain on tubing or dam^e may result.

1. Shut off power to unit. Failure to do so may

result in electrical shock. Remove unit com

pressor section access panels. Fig. 1 and 5.

2. Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service Techniques Manual, Chapter 1.

3. Remove core from suction and discharge line

Schrader valves.

11