Carrier 16JA User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

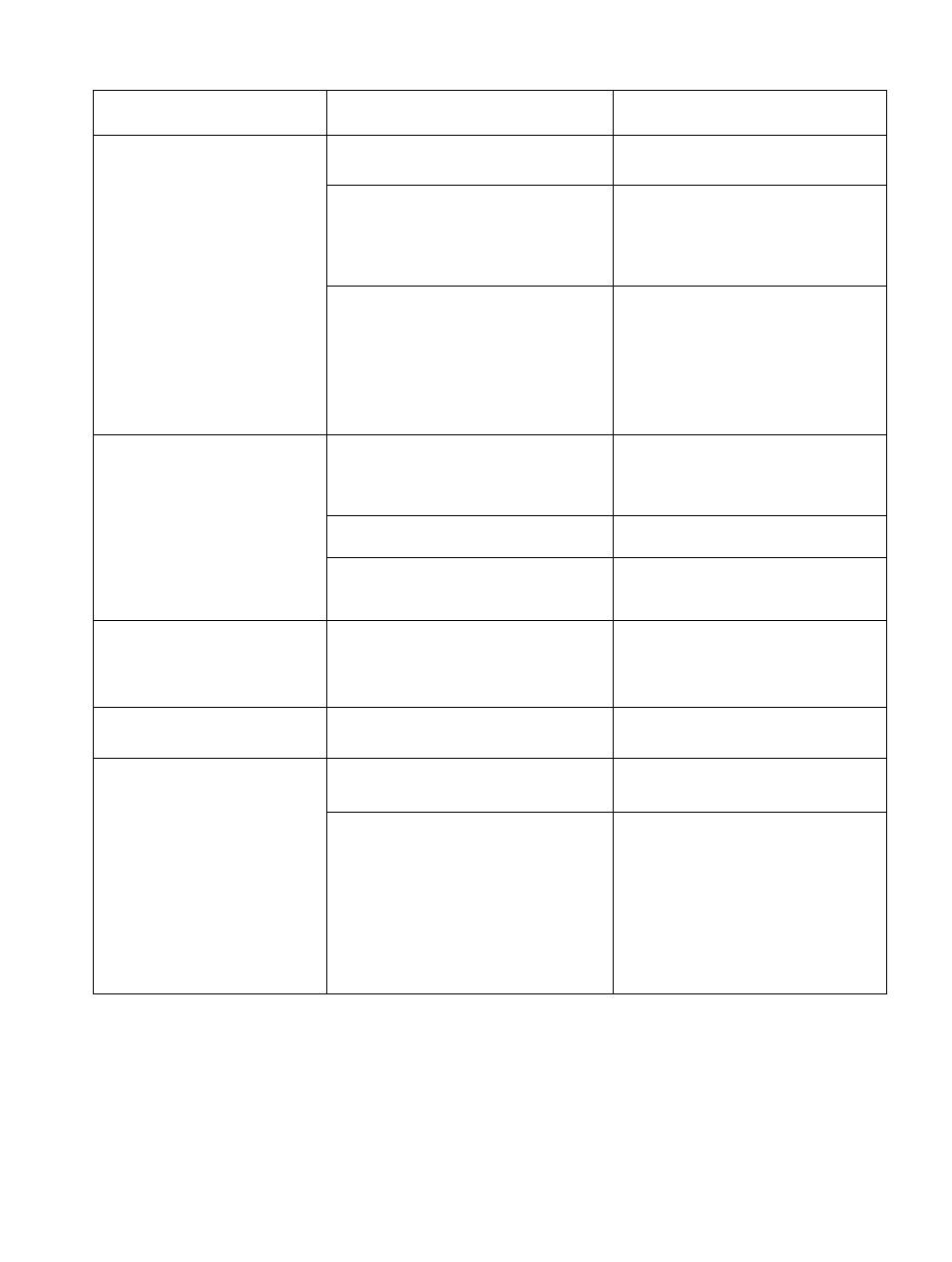

TROUBLESHOOTING GUIDE (CONT)

SYMPTOM OR DIFFICULTY

POSSIBLE CAUSE

REMEDY

D. Machine shuts down on

safety control.

1. Motor overloads.

1. Reset all motor overloads and

check reason for failure.

2, Hermetic pump overload has

tripped.

2. a. If pump is out of liquid, add

solution or water.

b. If pump is solidified, de-

solidify. (Refer to Solution

Desolidification.)

3. Shutdown on low-temperature

cutout.

3. a. Check low-temperature cut

out setting.

b. Control point adjuster set

ting too low. Turn up chilled

water controller to design.

c. Check condensing water tem

perature control.

E. Solidification during

shutdown.

1, Dilution cycle not long enough.

1. Check setting of dilution ther

mostat, Should be 140F. If still

solidifies reset to lower cutout

temperature.

2. Improper closing of capacity

control valve.

2. Check valve closure, Desolidify,

3. Machine is shut down, but con

densing water pump is still

running.

3. Manually shut down condensing

water pump.

F, Suspect air leakage.

Leakage into vacuum side of

machine.

Determine noncondensable ac

cumulation rate. Refer to the

Carrier Standard Service Tech

niques, publication SM-16.

G. Loss of vacuum at

shutdown.

Leakage into vacuum side of

machine.

Leak test machine.

H, Failure to keep ma

chine purged.

1, Leakage above the pumping rate

of purge.

1. a. Perform leak rate check,

b. Leak test machine.

2. Purge not performing properly.

2. a. Valves not opened properly.

Check to see that all valves

are in correct position,

b. Purge solidified. Desolidify.

c. Lack of solution flow to purge

from solution pump. Con

tact

your

Carrier

repre

sentative.