Selection procedure (with example), Performance data – Carrier 30HR User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

I Determine the unit size and operating conditions required to

meet the given capacity at the given conditions.

GIVEN;

Capacity ........................................................................................ SOTons

Leaving Chilled Water Temp (LCWT) .............................................. 44 F

Chilled Water Rise............................................................................... 10 F

Entering Condenser Water Temp .....................................................85 F

Fouling Factor (Cooler and Condenser)............................................ 0005

FOR 30HR (WATER-COOLED CONDENSER):

Enter the Ratings table marked 44 F Leaving Chilled Water

Temperature. Read down the left column (CAP ) to 80 tons

Note that either a 080 or 090 unit may be selected. Final unit

selection should be based on present and future job requirements

and the economics of the job. For this example, data from the

table is shown below for a 080 unit.

SELECTION PROCEDURE (With Example)

II Determine from Ratings table operating data for selected unit.

Unit............................................................................................... 30HR080

Saturated Discharge Temp (SDT)....................................................... 107.0 F

Compressor Motor Power input (KW).......................................... 75.9 Kw

Total Heat Rejection (THR) ....................................................101.5 Tons

Cooler Water Flow ..................................................................192.0 Gpm

Cooler Water Pressure Drop (PD).................................................. 10.7 Ft

Condenser Water Flow........................................................... 229.4 Gpm

Leaving Condenser Water Temp (Lwt)...........................................95.6 F

Condenser Water Pressure Drop (PD) ........................................... 12.0 Ft

For fouling factors other than .0005 refer to the Correction For

Fouling Factors table to: adjust the required capacity, correct

the compressor power input, and correct the actual condenser

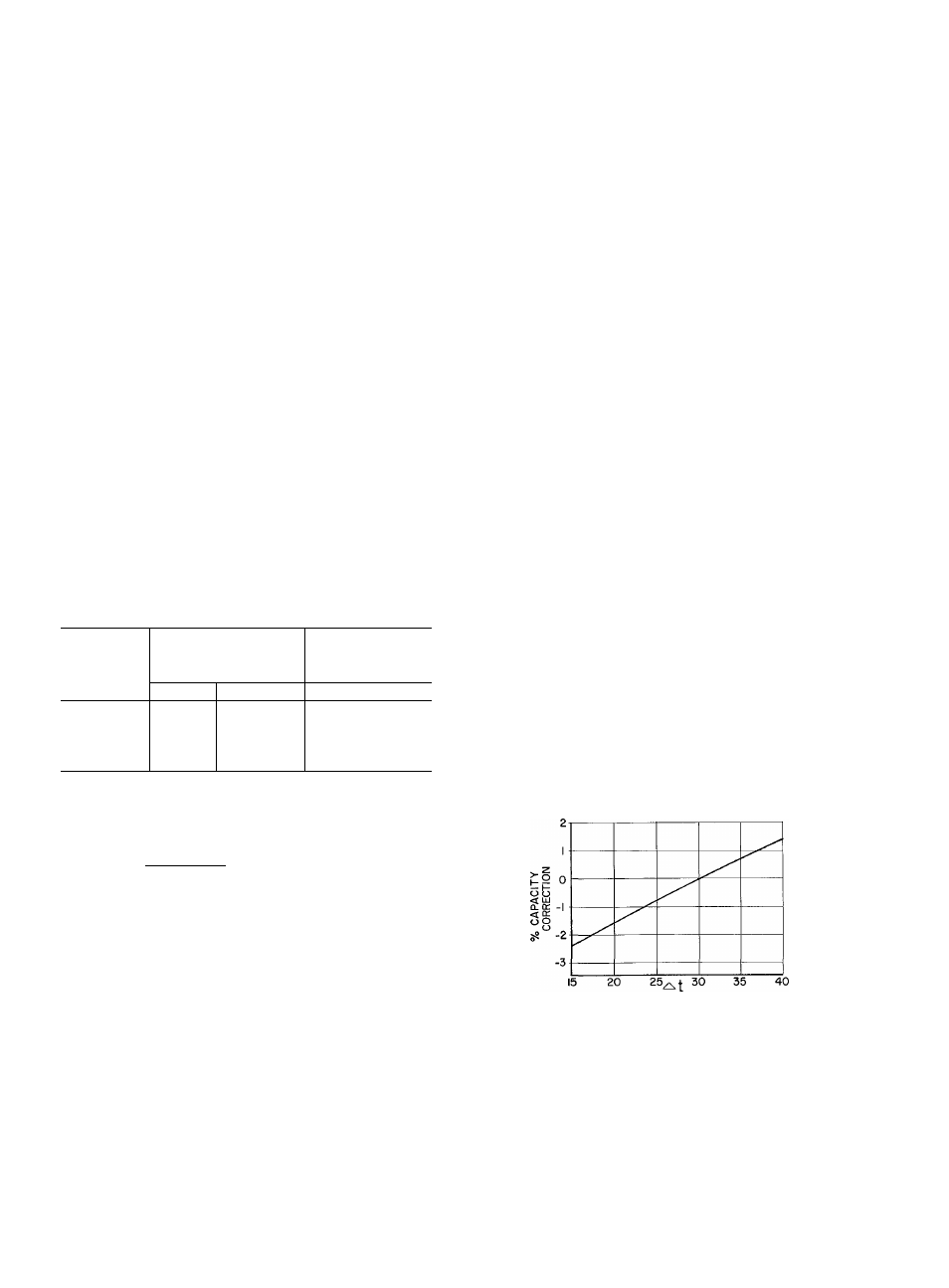

water quantity required. ForA t (SDT — entering cond water

temp) other than 30 F, refer to curve.

FOR 30HS (CONDENSERLESS):

Use the same method, with the exception that the condenser

water data do not apply. For the remote condenser data, refer to

appropriate Carrier condenser data publication.

PERFORMANCE DATA

CORRECTIONS FOR FOULING FACTORS

Ratings are based on .0005 fouling factor in the cooler and

condenser. Correction factors for other fouling factors are given in

the following table:

CORR FACTOR

CORR FACTOR

FOULING

FOR CAPACITY

FOR

FACTOR

AND COND WATER

POWER INPUT

Cooler

Condenser

Condenser

Clean

1.01

1 02

98

.0005

1 00

1.00

1.00

.001

.98

1 03

.002

-

.94

1.10

To correct capacity, adjust as follows:

a Adjusted required capacity (use to enter table)

_______ required capacity________

cooler factor x condenser factor

b. Actual compressor power input

= compressor kw (from table) x correction factor for

power input

c. Actual condenser water quantity

= gpm (from table) x cooler factor x condenser factor

Ratings based on: 10 F chilled water rise (suitable for 5 F to

15 F rise without adjustment), .0005 fouling factor in cooler (and

condenser on model 30HR), 15 F subcooling, and R-22.

Ratings in boldface type (44 F chilled water page) are in

accordance with the latest ARI Standard 590. Conditions:

30HR — 44 F leaving chilled water temperature with 10 F rise,

95 F leaving condenser water temp with 10 F rise and .0005 fouling

factor in cooler and condenser.

30HS — 44 F leaving chilled water temperature with 10 F rise,

.0005 fouling factor in cooler, 105 F condensing temperature for

remote water-cooled or evaporative condenser, 120 F condensing

temperature for air-cooled condenser.

Ratings based on 15 F subcooling. On 30HR units this occurs at

30 F A t (SDT — entering condenser water temperature.) When a

30HR (water-cooled condenser) unit is selected at conditions other

than 30 F A t use the curve below to correct the ratings table

capacity.

RATINGS

The following ratings tables are for both 30HR (water-cooled

condenser) and 30HS (condenserless) models. Condenser water data

apply to model 30HR only. Ratings beyond limits shown and/or

brine ratings are available in Carrier Application Data publications.

Ratings shown for Saturated Discharge Temperature (SDT) over

120 F do not apply to model 30HR.

Correction = Ratings table capacity x percent capacity correction

(from above curve).

Above 30 F At add the correction to rating table capacity.

Below 30 F At subtract the correction from rating table capacity.

30HS units matched with remote condensers which have greater

than (less than) the 15 F subcooling in the ratings, increases

(decreases) system capacity. To adjust capacity, multiply capacity

ratings by 0,94, then adjust this result upward by 0 4 percent for

each degree F of available subcooling