Electrical data – Carrier 30HR User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

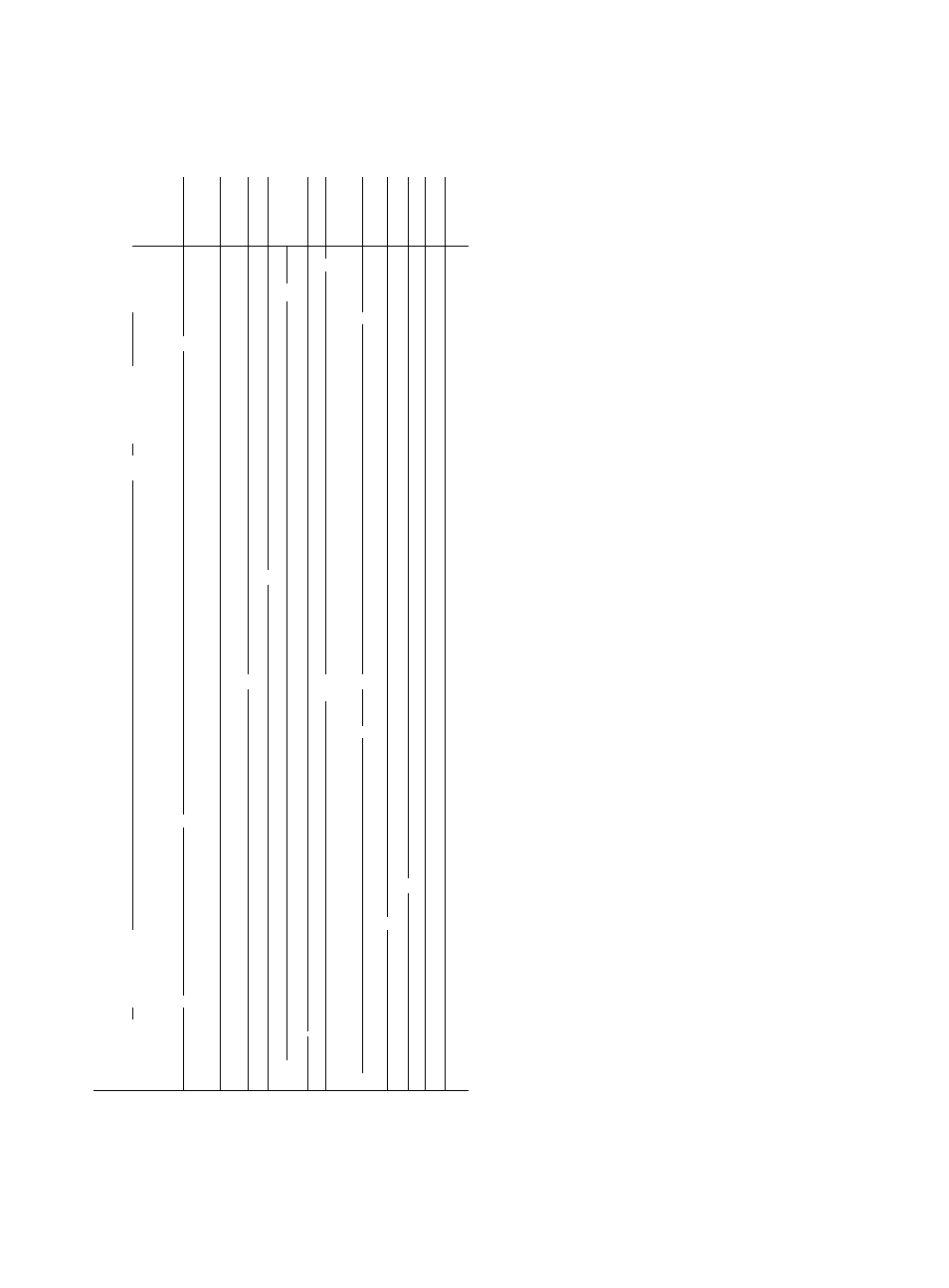

ELECTRICAL DATA

CAPACITY CONTROL STEPS

CONTROL SEQUENCE

#

TRANS SW POS 1*

TRANS SW POS 2*

UNIT

30HR

30HS

CONTR

STEPS

%

Cap.

Ope

Tot.

r C

Ck

Co

1

у Mr

1

mpt

£

ider

Ckt

ess

3t

s

2

or

4

%

Cap.

Ope

Tot.

r C

Ck

Co

Ì

yl i

f 1

2

nde

Ck

res

3t

rs

♦

2

sor

4

1

25 0

2 2

_

—

25 o’

2

_

2

040

2

50.0

4

2

_

2

_

50.0

4

2

2

_

3

75.0

6

4

_

2

75.0

6 2

4

_

4

100.0 8

4

-

4

-

100.0 8

4

-

4

1

40 Ò

4

4

—

— —

20

0

2

— —

2

050

2

60 C

6

4

—

2

60 0

6

4

_

2

_

3

80.0

8 6

_

2

_

80 0

8

4

_

4

_

4

100.0 10 6

-

4

-

100.0 10 6

4

-

- „ .

1

33.0

4

4

„

33 0

4

_

_

4

_

060

2

67.0

8

4

—

4

—

67 0

8

4

_

4

—

3

83.0

10 6

_

4

—

83 0

10

4

_

6

_

4

100.0 12 6

-

6

~

100.0 12 6

-

6

„

1

27.5

4

_

4

_

14 3

2 2

_

_

_

2

43 0

6

— _

6

_

27 5

4

4

_

_

_

3

57.0

8

4

4

_

43 C

6 2

4

_

070

4

71 4

10

_

4

6

_

57 0

8

4 4

_

_

5

71 4

10 2

4

4

_

71 4

10 2

4

4

_

6

85.7

12

4 4

4

_

85.7

12 2

4

6

_

7

100.0

14

4 4

6

-

100.0

14

4 4

6

-

1

25.0

4

_

_

4

_

25.0

4

4

_

_

_

2

37.5

6

_

_

6

_

37.5

6 6

_

—

3

50.Q

8

_

4

4

—

50 0

8

4 4

_

_

080

4

62.5

10

_

4

6

_

62 5

10 6

4

_

_

5

75 0

12

4 4

4

_

75 0

12

4 4

4

—

6

87 5

14

6

4

4

_

87 5

14

4 4

6

—

7

100 C 16

6

4

6

-

100

0 16

6

4

Ó

-

1

22.2

4

_

4

22

2

4

4

_

_

_

2

33 3

6

—

6

33 3

6 6

_

— _

3

55 5

10

_

6

4

_

55.5

10

4

6

_

090

4

66.7

12

6

6

_

66.7

12 6 6

— _

5

77.8

14

4

6

4

—

77 8

14

4

6

4

_

6

88.9

16

6 6

4

88

9 16

4

6 6

_

7

100

0 18

6 6 6

-

100.0

18

6 6 6

_

1

20.0

4"

4

_

20.0

4

_

_

4

_

2

30 0

6 6

_

_

—

30.0

6

6

_

3

40 0

8

4

_

_

4

40.0

8

4

4

- -

100

4

50 0

10 6

_

—

4

50 0

10

_

4

6

—

5

70.0

14

6

_

4 4

70.0

14

4 4

6

6

80.0

16

6

_

6

4

80 0

16

6

4

6

—

7

90 0

18

6

4

4 4

90 0

18

4

4

6

4

8

lOO.C

20

6

4

6

4

100.0 20 6

4

6

4

1

18 2

4

4

—

_

—

18.2

4

— —

4

—

2

27 3

6 6

„

—

27 3

6

— —

6

—

3

36.3

8

4

—

—

4

45 5

10

6

4

—

no

4

45 5

10 6

_

—

4

54 6

12

6

6

_

5

63.7

14

6

_

4

4

72 8

16

4

6

6

6

72.8

16

6

_ _

6

4

81 9

18

6 6 6

_

7

91 0

20 6 6

4 4

91.0

20

4

6

6

4

8

100.0 22 6 6 6

4

100

0

22

6

6 6

4

1

16 7

4

4

_

_

_

16 7

4

_

4

_

2

25.0

6 6

_

_

_

25 0

6

—

_

6

—

3

41.7

10

4

_

6

41.7

10

_

6

4

—

120

4

50 0

12 6

- ,

—

6

50.0

12

—

6

6

—

5

66

7 16

6

—

4

6

66.7

16

4

6 6

—

6

75 0

18

6

_

6 6

75.0

18

6

6 6

—

7

91.7

22 6 6

4

6

91 7

22

4

Ó

6 6

i 8

- —

100.0

24

6 6

6

100.0

24

6 6

Ó 6

1

29 G

6

6

—

— —

29 0

6

—

^ —

6

—

140

2

57.0

12

6

_

6

—

57 0

12

6

—

6

_

3

79 0

18

6 6

6

—

79 0

18

6

_

6 6

4

100.0

24

6 6

6 6

100

0 24

6 6

6 6

1

25 C

6

6

_

_

25 0

6

— —

6

—

160

2

50 0

12

6

6

50.0

12

Ó _

6

_

3

75.0

18

6 6

6

—

75.0

16

6

—

6 6

L i .

100

0 24

6 6

6

6

100

0 24

6 6

6

6

NOTE: Circuits and compressors numbered from ieft to right when

viewed from front of unit.

*Transfer Switch, manuaily operated

tCompressor No. 2 on two-compressor units.

Controi circuit power is 115 voits; it can be suppiied from

separate source or thru field-instalied accessory transformer Crank

case heaters are in control circuit, ahead of the START-STOP

switch: they are always operative as long as control circuit power

switch is on. Heaters are not affected if unit shuts off by safety

device action.

All units, ЗОН R,HS040 thru 160, have multiple-step temperature

controller,

factory

set

to

maintain

capacity

control

thru

return

chilled water temperature. On units 30HR,HS070 thru 120 the

Capacity

Control

system

includes

a

chilled

water

temperature

controller,

a

step

controller,

and

solenoid-operated

cylinder

unloaders on two compressors. All other units have a four-step

temperature

controller.

Units

ЗОН

R,HS040,050,060

have

a

solenoid-operated

unloader

on

each

compressor.

Units

30HR,HS140,160 have no unloaders.

Units 30HR,HS070 thru 120 have a separate control circuit

power

switch,

and

each

side

of

line

is

fused.

Units

30HR,HS040,050,060,140

and

160

have

one

double-pole

circuit

breaker, which serves as control circuit power switch and circuit

protection

Units 30HR,HS040,050,060 — Assume control circuit is powered

and circuit breaker is on. When START-STOP switch is turned to

"Start,” panel light will come on, control relays will be energized,

and timer motor will start. If temperature controller is calling for

cooling,

no

1

compressor

will

energize

in

0

to

5

minutes

depending on position of timer. If no 2 compressor is required, it

will start 15 seconds after no. 1. Timer motor stops at 15-second

point and temperature controller takes over, cycling compressors off

and on and loading and unloading cylinders in each compressor to

control cooling capacity in response to load requirements.

A recycle relay energized thru the timer ensures automatic

restart after power interruption, with a 5-minute delay from time

power is restored. Starting sequence same as above

Units 30HR,HS070 thru 120; When START button is depressed, a

24-volt transformer in the step controller is energized to provide

power

to

a

low-voltage

motor

wired

for

rotating

a

camshaft

clockwise

(unloading)

and

counterclockwise

(loading)

Factory-set

cams operate load switches which start or stop compressors and load

or unload cylinders to increase or decrease unit capacity as required.

Motor windings of camshaft drive motor are energized by a

balancing

relay

which

contains

windings

in

temperature

bridge

circuit

between

chilled

water

temperature

controller

and

motor

balancing potentiometer located at end of camshaft. When unit is

loading

or

unloading,

chilled

water

temperatures

correspond

to

respective positions of the camshaft. Camshaft rotation is limited in

each direction by limit switches.

Step controller also includes a recycle relay which ensures that

camshaft is fully recycled to unloaded position at start-up or after a

power interruption. After camshaft has recycled to unload position,

temperature

controller

starts

camshaft rotation

in

load

direction

which starts compressors in sequence, assuring staggered compressor

starting. While unit is operating, the cams on the step controller

protect compressors against rapid cycling.

To restart after power interruption, START button must be

manually depressed

Units 30HR,HS140,160 — Assume control circuit is powered and

circuit breaker is on. When START-STOP switch is turned to

"Start," panel light will come on, control relays 1 thru 4 will be

energized and timer motor will start. If temperature controller is

calling for cooling, one compressor will energize after delay of 10

seconds to 6 minutes depending on position of timer. Depending on

cooling

demand,

the

other

compressors

will

energize

at

brief

intervals until load requirements are satisfied. Thereafter, tempera

ture controller will cycle compressors off and on to control cooling

capacity in response to load requirements

A recycle relay energized thru the timer ensures automatic

restart after power interruption, with a 5-minute delay from time

power is restored. Starting sequence same as above.

15