Guide specifications – Carrier 30HR User Manual

Page 20

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

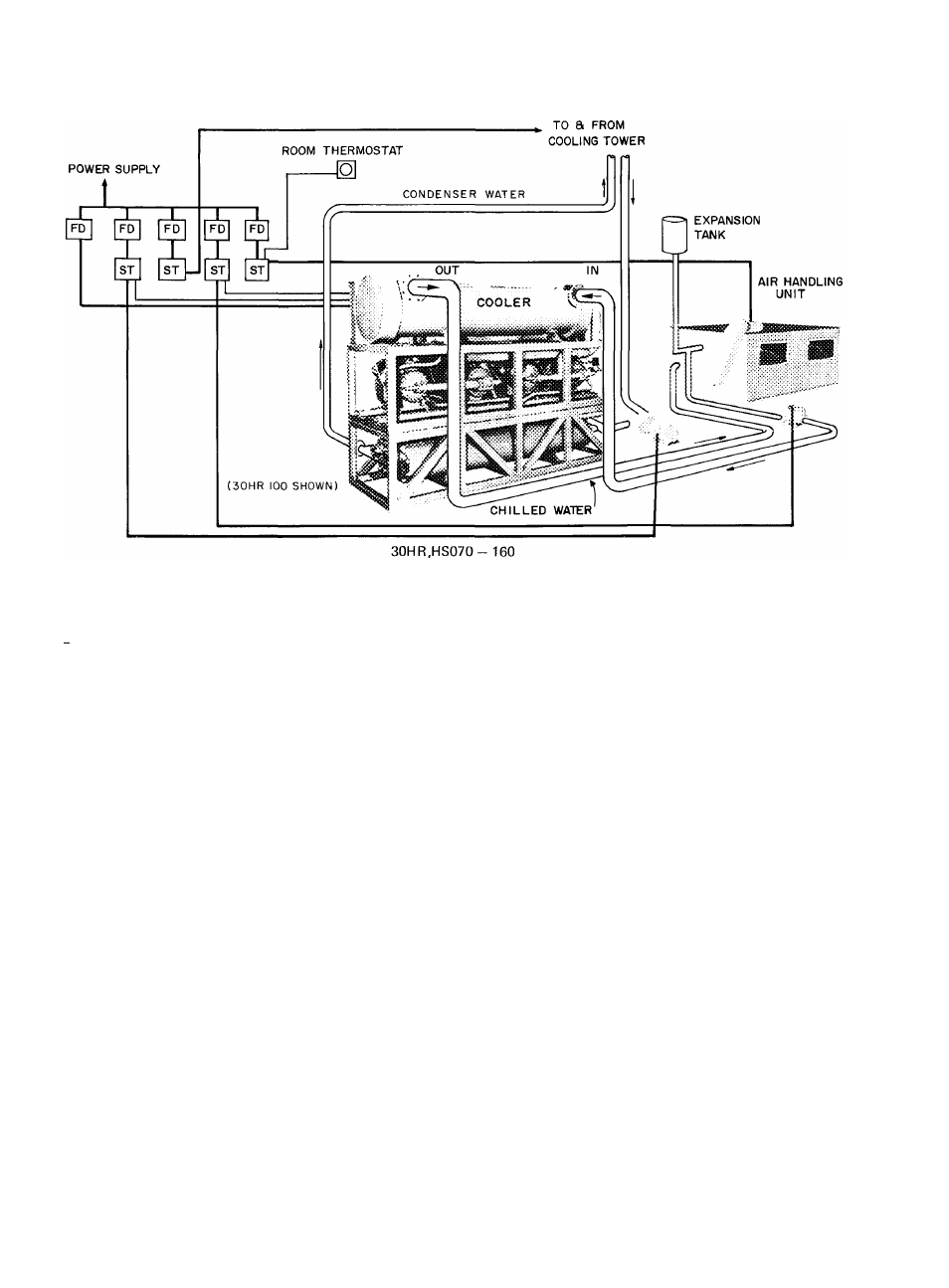

TYPICAL PIPING AND WIRING

FD

— Fused Disconnect

ST

— Starter

mmmmm

Power Wiring

--------- Control Wiring

n !>

Piping

NOTES:

1. Wiring and piping shown are general points-of-connection guides only and are not intended to be used,

or to include all details, for a specific installation

2 All wiring must comply with applicable local and national codes

3 All piping must follow standard piping techniques Refer to Carrier System Design Manual for details.

Furnish

and

Install

„

.factory-assembled

30HR

water-cooled

(30HS

air-

or

evaporative-cooled)

multiple

hermetic

compressor

liquid

chilling

package(s)

with

a

capacity

of

.tons

using

Refrigerant

22

Unit

shall

cool

gpm

of

water

from

_

F

to

F,with. . gpm of condenser water entering at . For

when operating at

F saturated discharge temperature Fouling

factor shall be _ in cooler and _ _ in condenser Cooler water

pressure

drop

shall

not

exceed

_

ft

Condenser

water

pressure

drop shall not exceed „ft

Construction and Ratings

shall be in accordance with lastest ARI

Standard

590

and

shall

comply

with

USAS

B9

1

safety

code.

National Electrical Code, and applicable ASME Code

Compressors

shall

be

reciprocating,

serviceable,

hermetic

type,

and shall have an automatically reversible oil pump and an operating

oil

charge

Compressors

shall

be

equipped

with

suction

and

discharge shutoff valves, and shall be mounted on spring vibration

isolators

Each

compressor

motor

shall

be

cooled

by

suction

gas

passing

around

the

motor

windings

and

shall

have

thermal

pro

tectors embedded in the windings Manual restart of unit shall be

required

after

motor

stoppage

due

to

thermal

overload

Each

compressor shall be equipped with an insert-type crankcase heater

to control oil dilution during shutdown

For each compressor there shall be a factory-installed contactor

and a calibrated

manual

reset, ambient

Insensitive magnetic circuit

breaker The circuit breakers shall open all three phases should an

overload occur on any phase

Cooler

shall

be

shell-and-tube

type,

with

removable

heads;

it

shall have two direct expansion refrigerant circuits Seamless 1/2-in

OD copper tubes shall be rolled into the tube sheets Shell shall be

covered

with

1-in

layer

of

closed-cell

foam

plastic,

vapor

barrier

insulation

Each Refrigerant Circuit

shall include: hot gas muffler; com

bination

moisture

indicator

and

sight

glass;

refrigerant

filter-drier;

liquid line solenoid valve; thermal expansion valve; charging valve.

GUIDE SPECIFICATIONS

All

suction

lines

shall

be

insulated

with

close-fitting

cellular

insulation Condenserless units shall have discharge line check valves

furnished for installations using remote condensers

Water-Cooled Condensers

(2 per unit) shall be shell-and-tube

type

with

integral-finned

copper

tubes,

and

shall

have

removable

heads

Construction

shall

comply

with

applicable

ASME

code Each

condenser shall be constructed to provide positive subcooling of the

liquid refrigerant A pressure relief valve, purge cock and a liquid

shutoff valve shall be provided on each condenser

Unit

shall

have

a

control

box

which

contains

high

and

low

pressure cutout switches for each refrigerant circuit; a manual reset

low

water

temperature

cutout

switch;

a

multiple-step

chilled

water

temperature

controller

to

ensure

staggered

starting

of

compressors

and to provide _ ..steps of capacity control

Mounted on control box of 30HS units, as standard equipment,

shall be

an

oil pressure safety switch for each compressor The

control panel shall have mounted on it a control power indicator

light,

individual

compressor

indicator

lights;

a

START-STOP

button

(switch); control power fuses (circuit breaker); a manual switch to

change starting sequence of compressors from one refrigerant circuit

to the other, and (except for 30HR ,HS040,050,060 units) a suction

pressure gage and a discharge pressure gage for each refrigerant

circuit

Unit shall operate on volt, phase, . Hz power It

shall be capable of operating within line voltage limits of _____________________

to . volts Control power shall be 115

V ,

60-Hz

Maximum Dimensions of Unit

shall be length .width

, height

Accessories

available for all size units shall include: oil-pressure

safety

switches

(HR

only),

control

circuit

transformer;

chilled

water

flow

switch;

insulated

enclosure

panels

For

all

sizes

except

30HR160:

condenser

water

manifold

package

For

30HR,HS040,

050,060 units only: two gage panels, each with a suction and a dis

charge pressure gage

C A R R I E R

Tab 15

Manufacturer reserves the right to change any product specifications without notice.

A I R C O N D I T I O N I N G C O M P A N Y • S Y R A C U S E ,

Form ЗОНR,HS-5P

Printed in U S A

Supersedes ЗОНR ,HS-4P, ЗОНR,HS-1 GS

6-69

Codes C and MA

N E W Y O R K

Catalog No 523-013