Carrier 30HR User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ELECTRICAL DATA (cont)

GENERAL NOTES

1. Compressor models 1 50, 250 and 266 are 4-cyl; 275 and 299 are

6-cyl.

2

Max incoming wire size for 208, 230 volts Two- and three

compressor units have one terminal block, 3 wires, 350 MCM for

040-060, 500 MCM for 070-090 Four-compressor units have

two terminal blocks, 3 wires per block; 350 MCM for 100-120,

500 MCM for 140, 160

3

Max incoming wire size for 460, 575 volts; All units have one

terminal block, 3 wires; 0000 for 040-060, 350 MCM for

070-120, 500 MCM for 140, 160

4 Across-the-line start is standard for all units at all voltages To

obtain part-winding start, make following modifications

208-230 volts —

All units (040 thru 160) all compressors are factory wired thru

two contactors Add 1 5-second time delay relay for each

compressor, to actuate second contactor

460,575 volts —

30HR,HS040 thru 120: Add second contactor and 1 5-second

time delay relay for each compressor in unit

30FIR,HS140: Add second contactors for no 2 and no 4

compressors: add 1 5-second time delay relay for each com

pressor in unit

30HR,FIS160:

All

compressors

are

factory

wired

thru

two

contactors; add 1 5-second

time

delay relay

tor

each

compressor

in unit

5

On units 140 and 160, a manual switch is provided to cut no. 4

compressor out of the system during intermediate seasons to

reduce demand load

STARTING SEQUENCE TRANSFER

UNIT 30HR,HS

040-060

j

070-090 1 100-120 | 140,160

Switch Pos

Compressor Starting Sequence

1

1-2 1 3-2-1 1 1-4-3-2 1 1-3-2-4

2

2-1 j 1-2-3 1 3-2-1-423-1-4-2

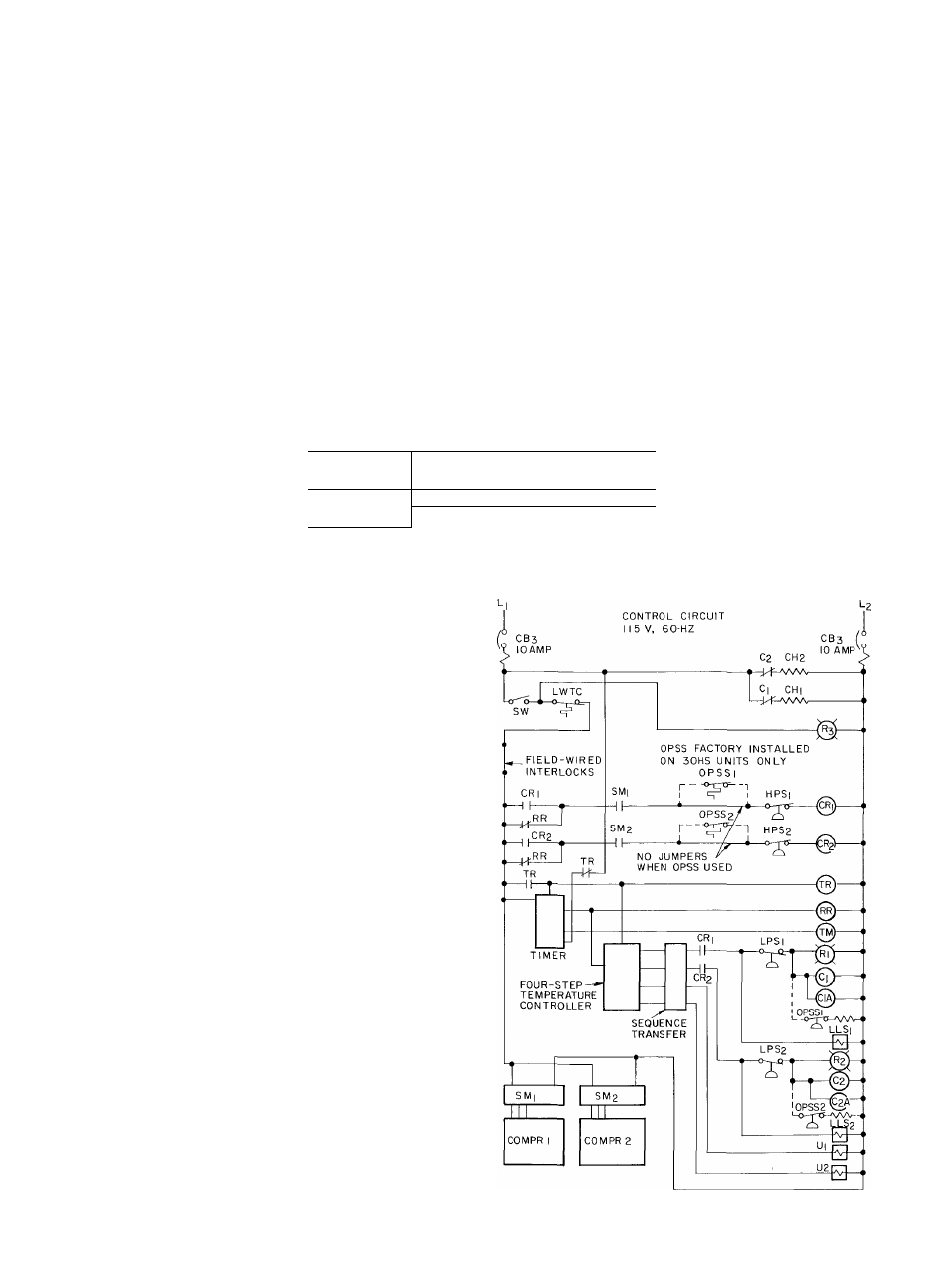

WIRING DIAGRAM, 30HR,HS040,050,060

LEGEND

C

— Compressor Contactor

CA

— Second Contactor

CB

— Circuit Breaker

CH

— Crankcase Heater

COMPR

—

Compressor

CR

— Control Relay

HPS

— High Pressure Switch

LLS

— Liquid Line Solenoid Valve

LPS

— Low Pressure Switch

LWTC

— Low Water Temperature Cutout

OPSS

— Oil Pressure Safety Switch

RR

— Recycle Relay

SM

— Sensor Module

(solid state compressor motor protection)

SW

— Switch (start-stop)

TM

— Timer Motor

TR

— Timer Relay

U

— Unloader (compressor)

_______ Factory Wiring

_______ Factory Wiring, 30HS only

0

Coil

Tl

Contacts Normally

Closed

1

I

Contacts Normally

Open

z®;

Light (Red)

17