Refrigerant charge – Carrier 19CB User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

r.

Refrigerant Charge

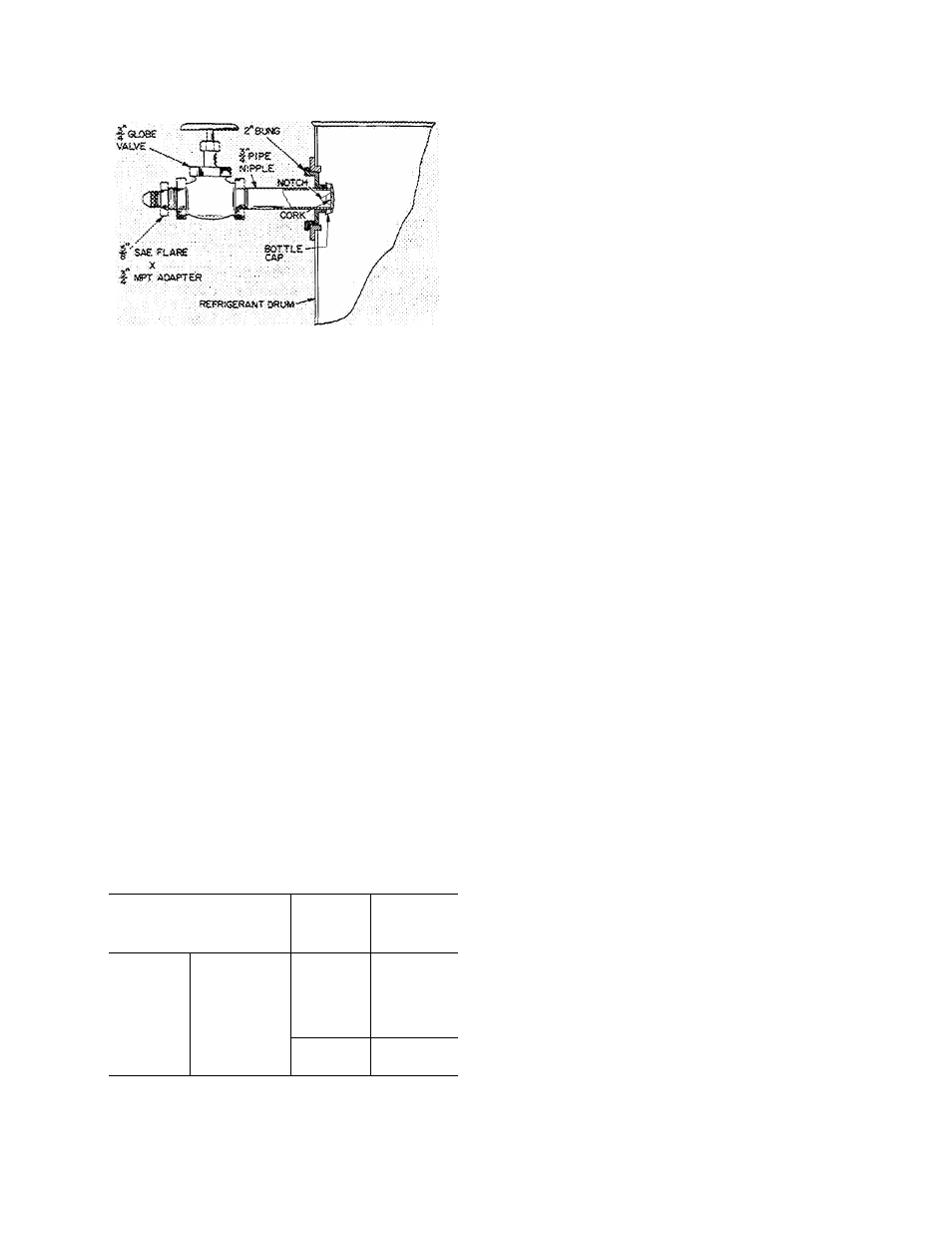

1. Install a charging valve in the 3/4-in. drum

opening as shown in Fig. 5.

3.

4.

Fig. 5 — Drum Charging Valve

Connect a short length of plastic hose or copper

tubing from drum valve to cooler charging

valve.

Circulate chilled water during the charging

process.

At a pressure less than that indicated in Table

2, liquid refrigerant will flash into gas and may

cause tube freeze-up. Keep refrigerant drum

upright and admit refrigerant as a gas until

cooler pressure is greater (smaller value of in. of

mercury vacuum) than that listed in Table 2.

Table 2 — Pressures Corresponding to 32 F

Saturation Temperature

REFRIGERANT

R-11

R-114

PRESSURE - INCHES

OF MERCURY VACUUM

18 05

3 85

5 The refrigerant supplied with the machine is in

excess of the amount required for initial charg

ing. Charge the amount shown in Table 3, less

200 pounds

6. After the machine has been started, it may be

necessary to adjust the charge for optimum

machine performance. For this adjustment, see

Trimming Refrigerant Charge.

Table 3 — Refrigerant Shipping Charges

MACHINE SIZE

Model Heat Exch

No.

^

Combn*

REFRIG

SHIPPING

CHARGE

19CB1200

19CB33-36

R-11

3200

19CB1300

19CB33-36

R-11

3200

19CB1400

19CB43-46

R-11

3750

19CB1500

19CB53-56

R-11

3750

19CB1600

19CB64-66

R-11

4000

19CB1800

19CB77-78

R-114

5400

19CB2000

19CB87-88

R-114

5400

*First 6 digits of 1 0-digit Machine Model code

Inspect Piping

Refer to piping diagrams provided in Job Data

and inspect piping to cooler, condenser and oil

cooler.

Chilled water should enter the lower nozzle of

the cooler and leave at the upper nozzle. Chilled

water temperature probe should be installed in

leaving chilled water hue.

Condenser water should enter the upper con

denser nozzle and leave at the lower.

Insure that pipes are vented and properly

suspended, with no stress on nozzles or on water

box covers.

Check to see that water flow agrees with design

flow. Pressure drop measurements across cooler

and condenser or across the pumps will indicate

approximate flow rate.

Oil cooler water must be clean, with 85 F

maximum temperature and 200 psi maximum inlet

pressure. Refer to tag attached to the inlet line for

pressure drop and velocity limits.

Field Wiring

WARNING: Do not attempt to check high

voltage supply without proper equipment.

Serious personal injury' cajr result.

Refer to Job Data wiring diagrams and check

field wiring as follows:

1. Connect voltmeter across incoming power wires

to compressor motor starter. Compare the

reading with voltage ratings on compressor and

starter nameplates.

2. Check that amperage rating on starter name

plate matches full load amperage rating on

compressor motor nameplate.

3. Ensure that voltage to oil pump starter agrees

with oil pump nameplate value.

4. Ensure that pumpout compressor voltage ^sup

ply agrees with motor nameplate.

5. Check that electrical supply to purge pump

(R-11) is 120 volts.

6. Test compressor motor and motor power lead

insulation resistance with a 500 volt insulation

tester such as a megohmmeter.

a Open starter nmin disconnect switch.

b. With tester connected to the motor side of

the starter contactor in the starter, take

60-second and 10-second megohm readings

as follows’

Six lead motor — Tie all 6 terminals together

and test between terminal group and ground.

Next, tie terminals in pairs, 1 and 4, 2 and 5,

3 and 6. Test between each pair while

grounding the third pair.

Three lead motor — Tie terminals 1,2 and 3

together. Test between terminal group and

ground.

c. Divide the 60-second resistance reading by

the 10-second reading. This ratio, or polar

ization index, must be 1.15:1 or higher.

Both the 10-second and 60-second reading

must be at least 5.0 megohms. If the

readings are unsatisfactory, repeat the test

at the motor terminals with power leads

disconnected. Satisfactory readings in this

second test indicate that the fault is in the

motor leads.