Carrier 19CB User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

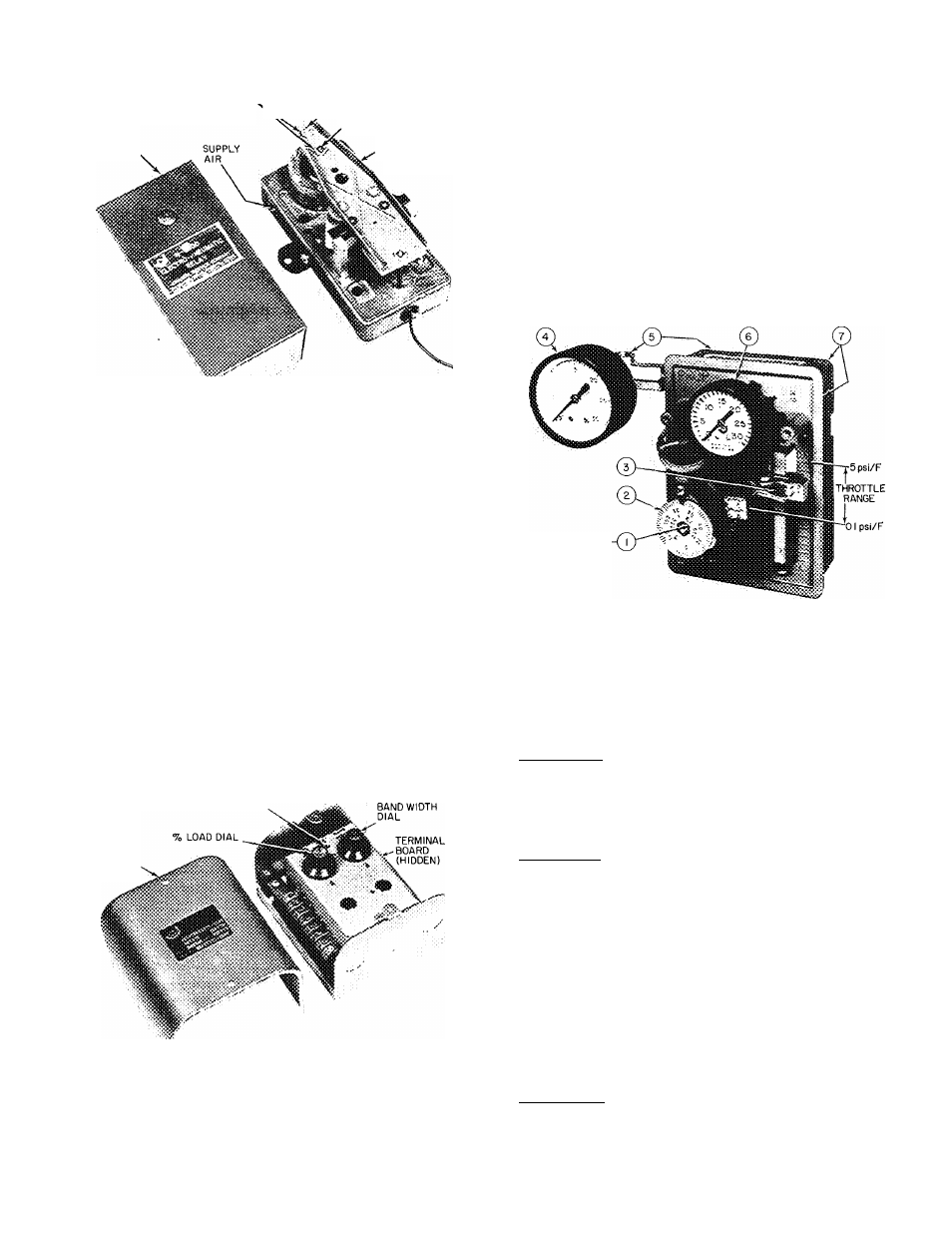

ELECTRO-PNEUMATIC RELAY

LOCKNUTS

SENSITIVITY SCREW

^SET POINT SCREW

COVER

CONTROL AIR

(OUTPUT)

This control is factory calibrated to provide a

linear output signal of 3 psi at 6 volts d-c to 18 psi

at 15 volts d-c. Field recaHbration should not be

necessary.

If calibration is required:

1. Establish 15 volt d-c input with 25 psi supply air.

2. Turn sensitivity screw to obtain 18 psi or higher

output.

3. Adjust setpoint screw, if required, to set output

at \ 8 ±V4 psi.

4. Reduce input to 6 volts. Output should be 3 ±

V4 psi. If low, turn sensitivity screw carefully

clockwise. If high, turn screw counterclockwise.

5. Recheck output at 15 volts. Repeat steps 3 and

4 if necessary.

DEMAND LIMIT CONTROL

CALIBRATION

ADJUSTMENT

COVER

1. Set percent load dial at 100%.

2. Set band width dial at 3.

3. Turn the cahbration adjustment screw fully

clockwise.

4. Run machine at 100% FLA by adjusting dial on

chilled water thermostat.

5.

Turn calibration adjustment screw counter

clockwise until guide vanes just begin to close.

6. If hunting occurs, increase bandwidth and re

peat steps 4 and 5.

7.

If control cannot be calibrated with above

procedure, check voltage signal from resistor in

starter. At 100% full load, voltage between

termmals 23 and 24 inside control center must

be 3.0 ± 0.1 volts. If not in this range, check siz

ing of resistor in starter.

CHILLED WATER THERMOSTAT (Pneumatic)

HIDDEN

ITEM

1

2

3

4

5

6

7

DESCRIPTION

SET POINT ADJUSTING SCREW

THERMOSTAT DIAL

SENSITIVITY SLIDER

SUPPLY AIR PRESSURE GAGE

SUPPLY AIR CONNECTIONS

CONTROL AIR PRESSURE GAGE

CONTROL AIR CONNECTIONS

Preparation:

1. Ensure 25 psi supply air to thermostat.

2. Loosen Allen setscrew in sensitivity slider and

move slider halfway between midpoint and DA.

Retighten screw.

Calibration:

1. Turn thermostat dial until control air registers

15 psi.

2. Operate machine to reach design chilled water

temperature at design load. Maintain 15 psi

control air during pulldown by adjusting ther

mostat dial as required.

3. On reaching design chilled water temperature,

turn dial until control air pressure holds

machine at design conditions.

4. Hold set-point adjusting screw stationary within

the dial post and set the thermostat dial at de

sign chilled water temperature.

Completion:

If vane hunting occurs, move sensitivity slider

away from DA. Throttle range may be narrowed or

widened by moving slider between the limits of 0.1

psi/F at midpoint to 5 psi/F at DA.

11