Service, Table 5 — gas rate (cfm) – Carrier 48EL User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Automatic changeover type thermostat is required.

Continuous Fan Operation — With power supplied

to unit and fan switch at ON position, indoor fan

remains on at all times.

Complete Shutdown or Change from Heating to

Cooling

1. Turn thermostat selector switch to OFF.

2. Remove heating section access panel.

3. Turn manual shutoff valve (Fig. 6) to PILOT.

Then depress valve and turn to OFF.

4. Turn off power. Replace access panel.

SERVICE

Adjusting Main Burner Gas Input (Refer to Fig. 4

and 6 and to Table 4 and 5) -- Need for adjustment

is determined by comparing measured gas input

(flow rate or manifold pressure) against the rated

input of a gas with a specific heating value. Check

local gas supplier for correct heating value (BTU’s

per cu ft). Before measuring, shut down all other

gas appliances.

Flow rate (cfm), the most accurate method, is

measured by gas meter and stop watch. Check

measured flow against rated flow in Table 5.

^

Table 5 — Gas Rate (cfm)

UNIT

48EL006

48EM006

Natural 1000

1 83

2 50

Natural 1050

1 74

2 38

Natural 1100

1 66

2 27

Butane 3200

57

78

Propane 2500

73

1 00

2

.

3.

4.

5.

6

.

Manifold pressure (in. wg) is measured as

follows:

1. Remove heating section access panel.

Shut down unit and close gas supply line valve

(Fig. 4).

Remove pressure tap plug from main gas valve

(Fig. 6) and install pressure tap.

Attach U-tube water gage manometer to pres

sure tap and open gas supply line valve.

Start-iip heating system.

Measure gas pressure (in. wg) and compare with

rated pressure in Table 4.

To adjust pressure or flow rate:

1. Remove pressure regulator adjusting screw cap

on main gas valve (Fig. 6).

Turn screw slowly, clockwise to increase pres

sure (flow), and counterclockwise to decrease.

Replace adjusting screw cap.

Shut down heating system.

Close gas supply line valve, remove manometer

and replace pressure tap plug.

Open gas supply line valve and replace heating

section access panel.

2

.

3.

4.

5.

6

.

Refrigerant Charging — Standard 1/4-in. Schrader

service connections are provided on the high and

low sides of the refrigerant system for charging and

evacuation.

Amount of refrigerant charge is listed on unit

nameplate (also refer to Table 1). Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

Refrigerants.

Unit panels must be in place when unit is

operating during charging procedure.

NO CHARGE — Use standard evacuating tech

niques. After evacuating system, weigh in the

specified amount of refrigerant.

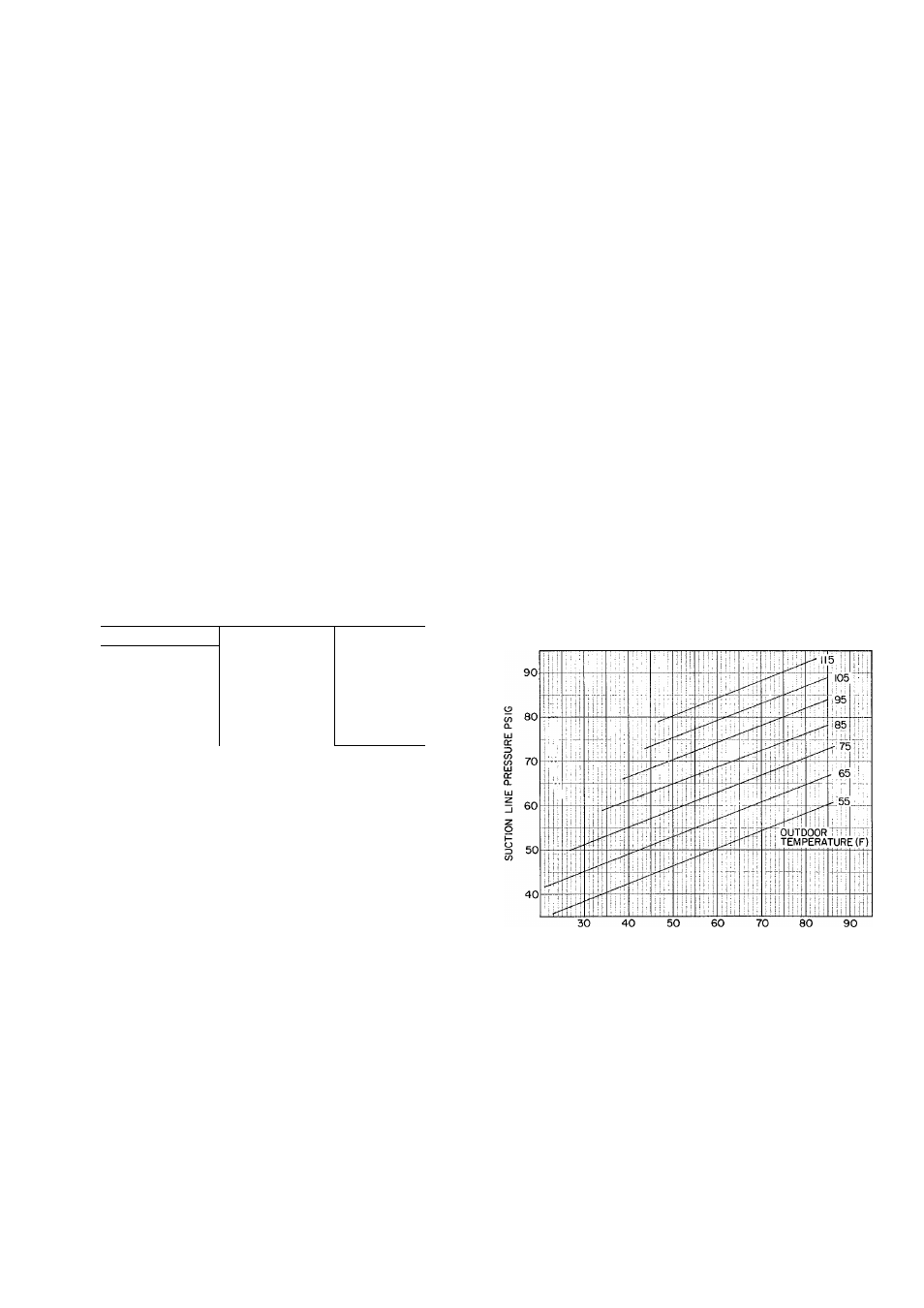

LOW CHARGE — Using charging chart (Fig. 8),

add refrigerant until the conditions of the chart

are met. Charts are based on charging the units to

the correct superheat for the various operating

conditions. An accurate pressure gage and tem

perature sensing device are required. Connect the

pressure gage to the service port on the suction

line. Mount the temperature sensing device on the

suction line and insulate it so that outdoor

ambient temperature does not affect the reading.

Indoor air cfm must be within the normal

operating range of the unit.

SUCTION LINE TEMPF

Fig. 8 — Charging Chart — 48EL,EM006

TO USE CHARGING CHART - Take the outdoor

ambient temperature and read the suction pressure

gage. Refer to chart to determine what the suction

temperature should be. If the suction temperature

is high, add refrigerant. If the suction temperature

is low, carefully blow some of the charge. Recheck

the suction pressure as charge is adjusted.

If Chargemaster® charging device is used, tem

perature and pressure readings must be accom

plished using charging chart. Fig. 8.