Carrier 48EL User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5.

7.

Pitch all horizontal pipe runs towards the unit

1 /4-in. per 15 ft to prevent trapping condensed

moisture.

Support piping to maintain proper pitch,

prevent strain on unit controls, and prevent

accidental movement of piping.

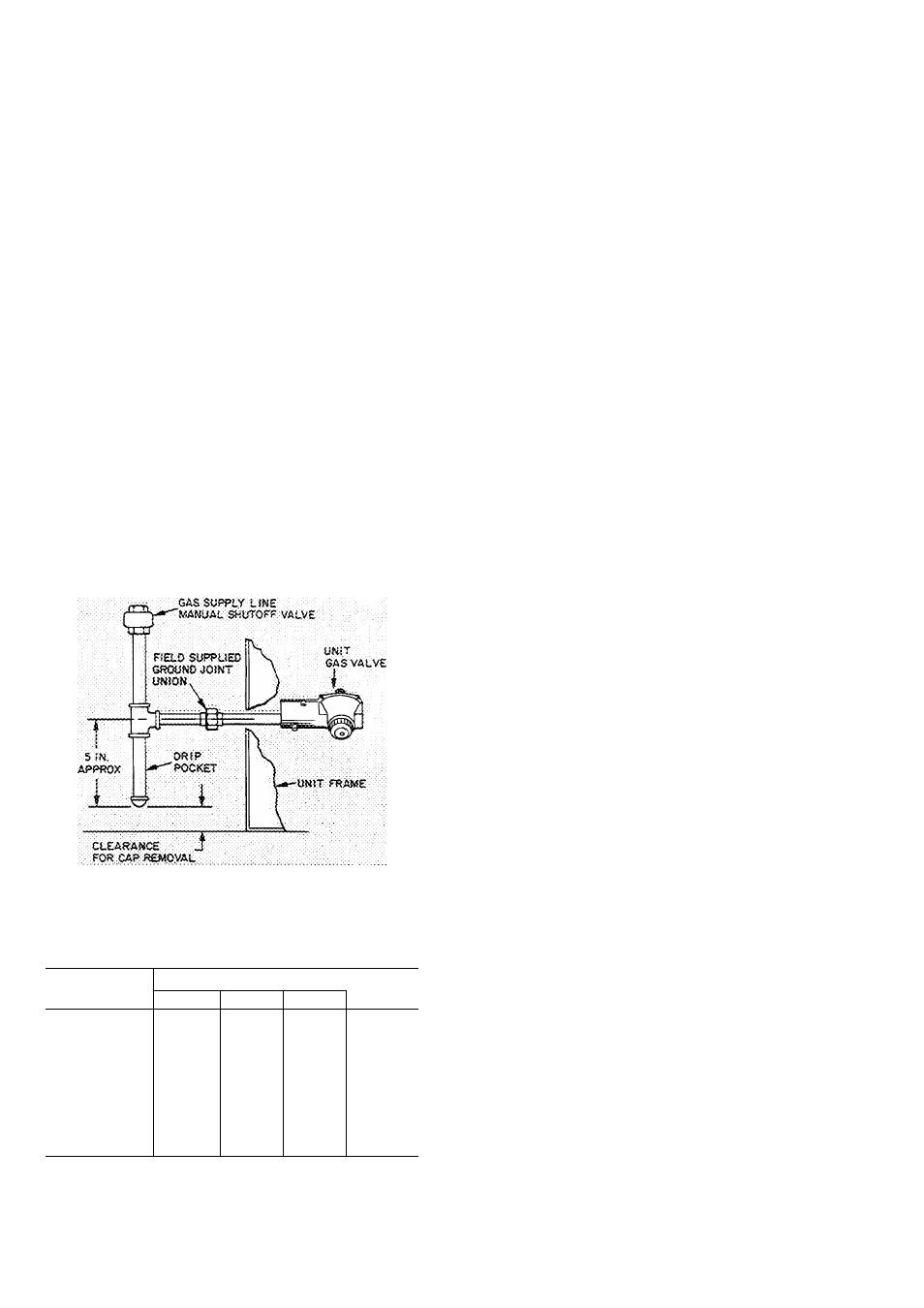

Install a tee for attachment of a dirt and

moisture drip pocket (Fig. 4). Tee should be at

same level or below gas valve connection. Drip

pocket must be protected against freeze-up

Install manual shutoff valve on gas piping per

local codes.

8. Provide a ground joint union in the gas supply

line near the unit gas valve.

9. Protect gas piping from freezing temperatures

Gas stoppage can result from failure to insulate

pipe against wide or sudden temperature

changes.

10. When piping is completed, check entire gas

assembly and field piping with soap and water

solution.

Never use an open flame for leak testing.

NOTE Connection to unit gas valve is 1/2 in FPT

Fig. 4 — Gas Piping Details

Table 2 — Maximum Pipe Cap. (cfh)*

PIPE

LENGTH (ft)

NOMINAL PIPE SIZE (in.)

1/2

3/4

1

1-1/4

10

132

278

520

1050

20

92

190

350

730

30

73

152

285

590

40

63

130

245

500

50

56

115

215

440

60

—

105

195

400

70

—

96

180

370

80

—

90

170

350

90

—

84

160

320

100

—

79

150

305

*Cfh — Cu ft/hr based on 0 3 in wg pressure drop and 0.6

gas specific gravity

NOTE: Correction is not necessary for normal number of

fittings nor for 0.7 gas specific gravity unless specified

Drain Piping — The condensate drain connection

(3/4-in. MPT) is on service access face of unit

(Fig. 1). Since drain is on the suction side of the

indoor (evaporator) fan, it must be trapped to

prevent leakage back into the unit. Trap should be

at least 3 in. deep and should be formed of flexible

material or in such a manner as to resist freeze-up

damage.

Wiring — The design center voltage for each unit is

stamped on the unit nameplate. The supply voltage

at the unit must be within maximum and minimum

limits shown on nameplate and in Tabled. Phase

unbalance on 3-phase units must be within 2%.

Contact local power company if correction is

necessary. Operation of the unit on improper line

voltage or with excessive phase unbalance is con

sidered abuse and is not covered by Carrier warranty.

Provide a branch circuit fused disconnect of

adequate size to handle unit starting current

(Table 3). Disconnect must be within sight of and

readily accessible from the unit in accordance with

Section 440-14 of the National Electrical Code

(NEC). Provision for locking switch at open (off)

position is advisable to prevent power from being

turned on while unit is being serviced.

Use only UL approved copper or copper-clad

aluminum power wires.

UNIT CONNECTION

1. Attach field power conduit to 1-1/8 in. hole at

front of high voltage (line wiring) junction box

(Fig. 1).

2.

Run conduit so that access panels can be

readily removed.

3. Splice field power wires to the pigtail leads in

the junction box. Wire nuts are provided for

either copper or aluminum wire. These must be

field insulated.

4. Route the control-voltage field wiring thru the

7/8-in.

hole

in

low-voltage

junction

box

(Fig. 1). If conduit is not used, protect wires by

inserting diaphragm grommet into the hole.

Make all connections to pigtail leads, but do

not use aluminum control wire for splice

connection to the copper pigtails.

Accessory Installation and Wiring

REMOTE CONTROL CENTER - The installation

instructions for this combination heating-cooling

thermostat and subbase are included with the

accessory.

Locate the thermostat on an inside wall or

column where it is affected only by the average

temperature of the room. The subbase has slots for

direct mounting on wall or on vertical outlet box.

Run the thermostat cable or equivalent single

leads of no. 18 colored wire from subbase ter

minals to 7/8-in. diameter hole in access side of

unit (Fig. 1) and attach to low voltage (control

wiring) terminals in junction box (Fig. 5).