Filter installation (field-supplied), Assemble wind cap and combustion-air inlet box, Assemble (fig. 2) – Carrier 48EL User Manual

Page 3: Piping and wiring

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Ductwork Installation — For air duct system design

information, refer to Carrier System Design

Manual, Part 2. System airflow must be within the

range of temperature rise and external static

pressure shown on the unit A.G.A. rating plate.

Bolt or screw ductwork to unit supply and

return air duct flanges and seal joints with sheet

metal flashing. Flange location and dimensions are

given in Fig. 1. Use flexible connectors between

ductwork and unit to dampen vibration. If a single

split duct is connected to the unit, use a gasket to

prevent air bypass between supply and return sides.

Insulate and weatherproof all external duct

work. Secure ducts to building structure and

weatherproof all duct openings in wall or roof.

Ducts passing thru unconditioned spaces must be

insulated and provided with a vapor barrier.

Filter Installation (Field-Supplied)

1. Locate filter in return air system. Convenient

location for filter is inside building behind

return air grille. Size and number of required

filters is given in Table 1.

2.

Attach filter manufacturer’s instructions to

filter rack.

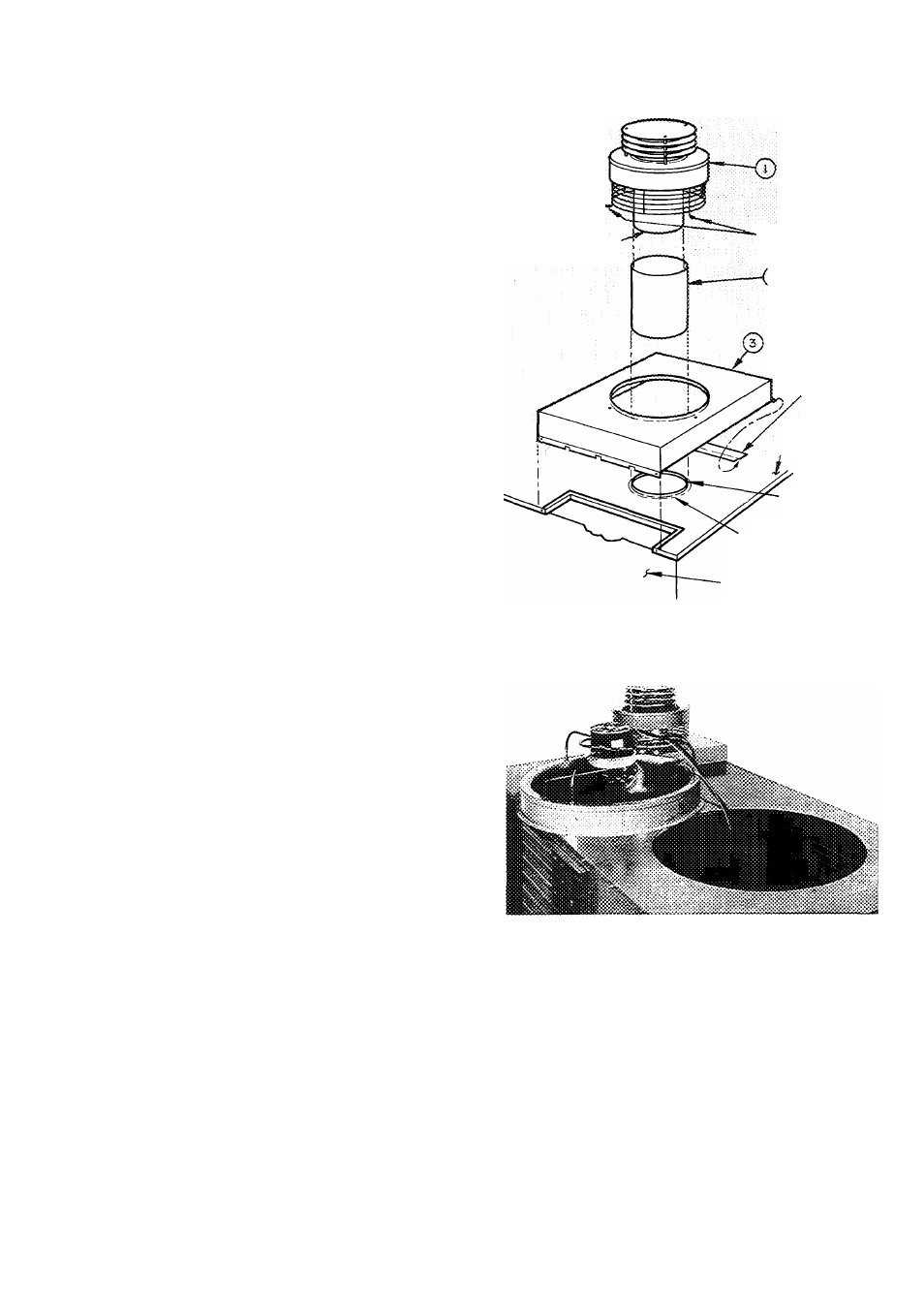

ASSEMBLE WIND CAP AND

COMBUSTION-AIR INLET BOX

Locate — The wind cap assembly, heat-shield collar

and combustion-air inlet box (items 1, 2 and 3 of

Fig. 2) are shipped within the condenser section

except 460 volt units.

On 460 volt units, only the combustion-air inlet

box is shipped within the condenser section. The

heat-shield collar and wind cap assembly are

shipped in a separate package.

Remove 6 sheet metal screws and lift condenser

fan, grille and orifice from the top of the con

denser section (Fig. 3). Remove and discard metal

banding securing the wind cap and/or inlet box and

remove the item(s) from the condenser section.

Before replacing the condenser fan, grille and

orifice, remove any shipping tape from the con

denser fan.

Assemble (Fig. 2)

1. Mount the combustion-air inlet box (item 3) by

sliding the horizontal box flange under the

retaining clip on the unit top cover. Fasten the

inlet box with sheet metal screws provided.

2. Place end of heat-shield collar and secure wind

cap assembly (item 1 ) with 3 sheet metal screws

thru wire cage eyelets.

PIPING AND WIRING

Gas Piping — Install piping per national and local

codes and ANSIZ223.1 entitled “National Fuel

Gas Code,” (published by American Gas Asso-

auEPiPc

(PARTOF WiNOCAP

ASS£M8LY)

WIND CAP

ASSSMSi-Y

EY£L£TS(3)

« yHSATrSHfEXP

‘^^COLtAR

COMBUSTfON

AiR

inlet

BOX

RETAININS

CUP

TOP

COVER

OF UNIT

!

TCP COVER

EXTRUSION

FLUE BOX

EXTRUSION

HEATING

SECTION

ACCESS PANEL

Fig. 2 — Wind Cap and Air Inlet Box Assembly

Fig. 3 — Removing Condenser Fan

and Orifice Assembly

ciation, 1515 Wilson Blvd., Arlington (Rosslyn),

VA 22209).

1. Furnish the gas line from the main gas supply

to the unit gas valve (Fig. 4). Connection at gas

valve is 1 /2 in. FPT.

2. Size the supply pipe for 0.3-in. wg maximum

pressure drop and for the volume of gas

required (Tables 2, 4 and 5). Pipe size must

equal or exceed size of gas connection at unit.

3. Use pipe dope approved for use with liquefied

petroleum (LP) gases.