И * й i [è, Table 3 — electrical data (60-hz) – Carrier 48EL User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

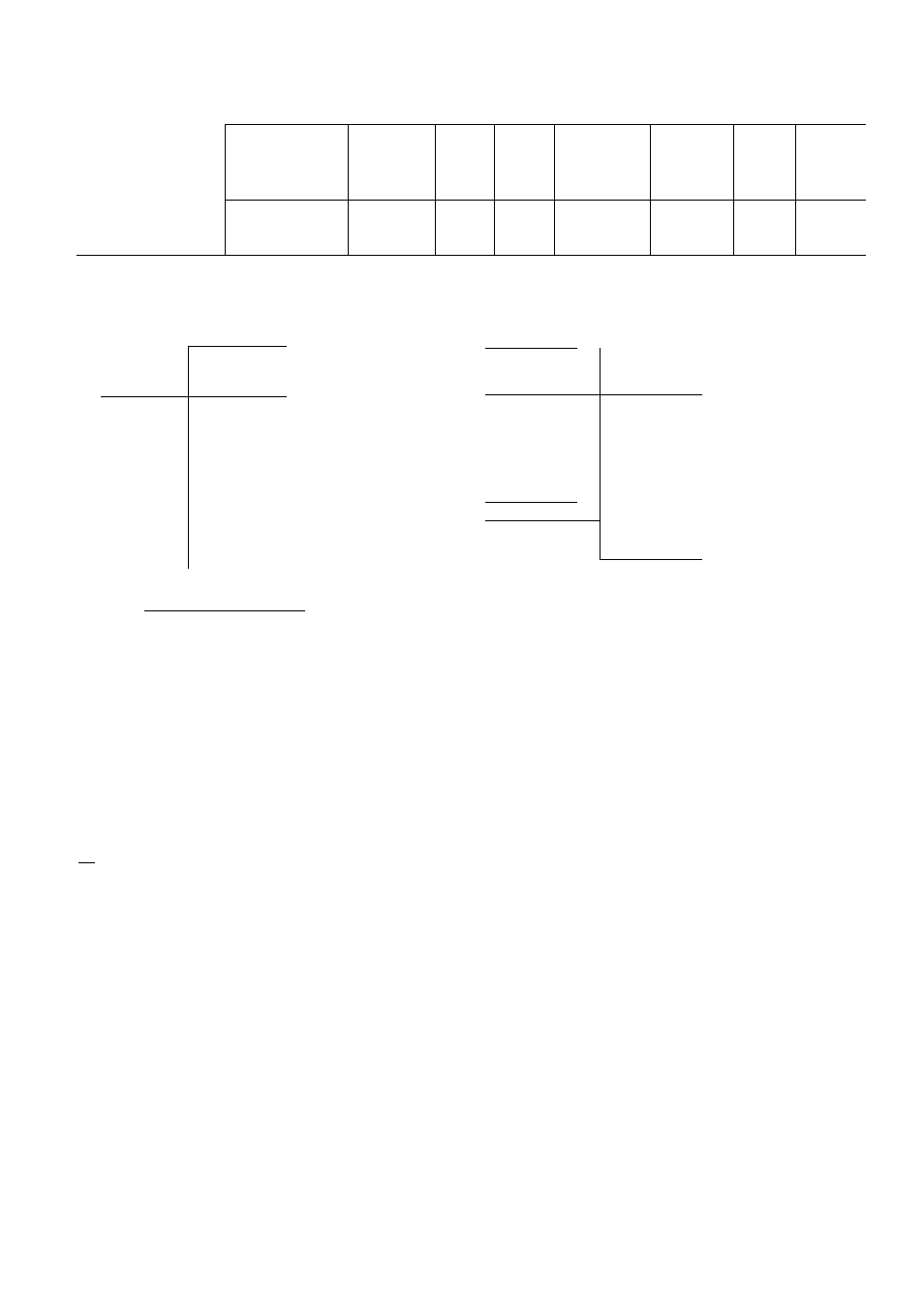

Table 3 — Electrical Data (60-Hz)

UNIT MODEL

VOLTA

Norn V/Ph/Hz

GE

Min-Max

CO

RLA

Ml PR

LRA

OUTDOOR

FAN

MOTOR

FLA

INDOOR

FAN

MOTOR

FLA

POWIEI

Min

Ckt

Amp

3 SUPPLY

Max

Fuse

Amps

48EL,EM006300,310

230/1/60

207-264

35 3

175

2.8

6 9

55

70

48EL,EM006500,510

208-230/3/60

187-253

22 7

132

28

6 9

40

50

49EL,EM006600,610

460/3/60

414-528

10.4

66

28

6 9

20

25

FLA — Full Load Amps

LRA — Locked Rotor Amps

RLA — Rated Load Amps

Table 4 — Gas Data — 48EL,EM006

TYPE

BTU

OF

PER

GAS

CU FT

1000

Natural

1050

1100

Butane

3200

Propane

2500

Propane

2500

SPECIFIC

GRAVITY

60

65

60

60

_65^

2

00

1 53

1 53

MANIFOLD

MAIN

PRESSURE

BURNER

(in. wg)

ORIFICE

3.3

3.5

30

3.2

#41 Drill

27

2.9

12.2

#54 Drill

_

108

#53 Drill

PILOT

ORIFICE

.023 in

009 in

.009 in

THERM O STAT CO M BINATIO NS FO R ALL UNITS

1

HH07AT074 AND SUBBASE HH93AZ076

2

HH0IAD042 AND SUBBASE HH93AZ042

3

HH0IAD040 AND SUBBASE HH93AZ040

I I I I I

I

BRN

I

BLK

I

RED BLU O RN

BLU

—

— BLK -

-YEL^

I 1

I I I I I

И * й I [È '

^

^ FIELD PO W ER

FIELD

CO NTRO L

W IRES

W IRES

Field Power Wiring

Field Control Wiring

Factory Wiring

I I

Thermostat Connections------------------

_$^Splice Connection

----------

*Not connected when single-phase power input is used.

Fig. 5 — Remote Control Wiring

for Thermostat Combinations

When thermostat wiring is complete, mount

thermostat to subbase per instructions included

with the control. Do not turn on unit power at this

time; refer to Start-Up section of this publication.

Thermostat heat anticipator setting is 0.6 amps.

REMOVE SHIPPING TAPE on condenser fan, if

not previously removed.

CHECK COMPRESSOR HOLD-DOWN BOLTS -

Compressor is internally spring-mounted. Do not

loosen or remove hold-down bolts.

SET HEAT ANTICIPATOR on thermostat at 0.6

amps.

OPEN GAS SUPPLY LINE VALVE and purge line

by loosening ground joint union (Fig. 4). Tighten

union when gas odor is detected.

ADJUST BLOWER SPEED, if required, to main

tain heat temperature rise limits given in Table 1.

CHECK MAIN BURNERS

1. Measure and adjust main burner gas input as

described in Service section.

2. Turn main gas valve to ON position and operate

unit for at least 15 minutes with all access

panels in place.

3.

With unit operating, remove heating section

access panel. Check burner flames. Flames

should be clear, almost transparent blue. If

flames appear yellow, a change to factory set

primary air adjustment has occurred. Refer to

Fig. 7 and readjust primary air as follows:

Loosen primary air spoiler locking screw.

Rotate

adjustment

tab

counterclockwise

(slightly) until flame becomes blue. If flames

lift off burner ports, turn adjustment tab

clockwise. Retighten locking screw.

FINAL HEATING SYSTEM CHECKOUT - Move

thermostat dial above and below room temperature

setting several times, pausing at least 5 minutes

between cycles. Check pilot flame, main burner

ignition, flame characteristics and indoor (evap

orator) fan motor time delay relay operation.

Replace heating section access panel.

COOLING SYSTEM CHECKOUT

1. Turn power on.