Carrier 38GK User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

8 Add charge by slowly opening Chargemaster®

valve. If necessary, reduce charge by bleeding at

liquid line service valve. Check outdoor air and

evaporator temperature during procedure. If

they change, refer back to Suction Line Tem

perature table for new value.

Correct use of Chargemaster ensures an opti

mum refrigerant charge will be in system when

conditions and system components are normal.

However, the Chargemaster does not solve or fix

system abnormalities. It indicates correct charge

for condition of system. It will not make correc

tions for dirty filters, slow fans, excessively long or

short suction lines or other abnonnal conditions.

This charging device ensures that a correct relation

ship exists between outdoor temperature, evapora

tor temperature, and suction line temperature on a

specific system.

Charging By Weight

— Remove any refrigerant

remaining in the system before recharging. A

Dial-a-Charge cylinder may be used to recharge the

system with reference to nameplate for correct

system charge.

SERVICE

Access to all controls and unit components is

thru rear access panel.

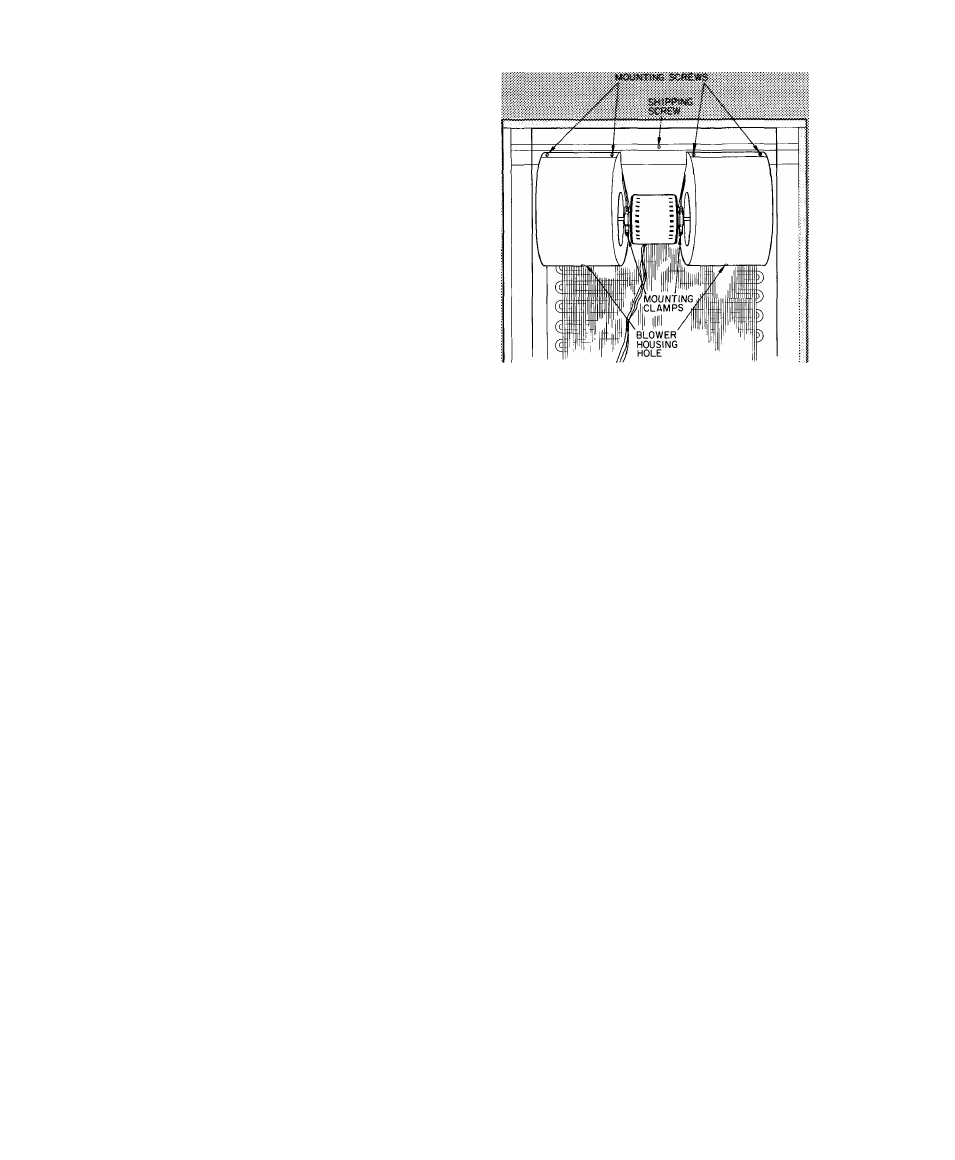

Blower Wheel and Motor Removal

— The blower

assembly may easily be removed thm the rear

access panel in the following manner’

1. Shut off all power to the unit.

2. Loosen and remove 3 screws holding the rear

access panel in place and remove the rear

access panel from the unit. See Fig. 5.

3. Disconnect the 2 electrical leads from the

blower motor to the compressor contactor.

4. Remove the 2 screws from the motor mount

ing clamps, the 4 mounting screws from the

blower housings and remove both housings

from the rear flange.

5. Insert a 3/8 x 9 in. long Allen wrench into the

hole at bottom of the blower housing.

6. Loosen and remove the setscrews on both

blower wheels and remove the wheels from the

shaft.

7 Lift out motor. Motor may be replaced at this

time, if necessary.

8. Place both wheels into each housing, and insert

motor shaft of motor thru housing and blower

wheel for proper wheel positioning.

9. Place blower housing onto the rear flange.

10. Start the 4 mounting screws of the blower

housing and align the blower motor between

the mounting brackets.

Fig. 5 — Rear Access Panel Removed

11. Place a brace between the blower motor and

the compressor to support the motor.

12. Attach the rear clamp, first, then the front

clamp to the motor mounting brackets before

tightening the clamp screws.

13. Rotate the blower wheel until the bottom

holes of the blower housing, the large hole in

the blower wheel, and the Allen setscrews are

aligned.

14. Adjust and tighten the blower wheels in

position on the motor shaft, using the Allen

wrench.

15. Tighten the 4 mounting screws of the blower

housing.

16. Connect the 2 electrical leads from the blower

to the compressor contactor. Make sure both

speed taps of the motor are not energized at

the same time.

17. Replace the rear access panel and tighten the 3

screws.

18. Turn on power to unit.

38GK Unit Single-Phase Compressors

of the split

capacitor (PSC) type require an equalized system

pressure to start. (Equalization takes approxi

mately 3 minutes.) When supply voltage is within

permissible limits and compressor does not start,

give compressor a temporary capacitance boost.

See Carrier Standard Service Techniques Manual,

Chapter 2, for details. Use a 130 mfd start

capacitor. Run compressor for 10 minutes, then

shut off and allow system pressure to equalize. Try

restarting without boost capacitor. If after 2

attempts (without boost capacitor) the compressor

does not start, add an accessory start capacitor

relay package.