Comti^tes ainm 813.4 h not hy omor, Wsrrsniy – Carrier 38GK User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

4. Pressurize the system with refrigerant to 10 psig

and backseat (turn counterclockwise) both

service valves.

5. Remove the refrigerant cylinder. Replace the

valve stem and service port caps on both service

valves (be sure they are tight) if system is to be

left in purged condition.

ELECTRICAL DATA AND WIRING

Table 5 — Electrical Data

COND

UNIT

001

002

003

V/PH

208TÌ'

2

’

30

/i

208/1

230/1

208/1

230/1

OPER*

VOLTS

Max

229

253

229

253

229

Min

8/”

207

COMPR

L R A

60 0

51 0

1

T

2

'

11

0

FAN

BRANCH CIRCUIT

i rusei

Wire F

mo

X :

re

Si zet

F f t

FLA (AWG)iWire

Amps

1 9

174 0 115 5 1

8/

S0,b|15,? ,

!o I

0

113

.

6 I

20/'

72,0 14J I

1.94.0 1/0.5

Í 12

1 37

25

i 12

1 44

25

: in

1 /Iß

llili

'2

i 3d

1 12 1 37

30

liiii

A

33

■ 10

45

iiiii

253 1207

Electrical data for unit models with 06M compressor

FLA — Full Load Amps

LRA — Locked Rotor Amps

‘Permissible limits of the voltage range at which the units will oper

ate satisfactorily

/Copper wire sizes and lengths. Use latest National Electrical Code

(NEC) for aluminum wire sizes

/Maximum dual element fuse size

NOTES:

1 Control circuit voltage is 24 volts on all units

2 Aluminum field wiring may be used

Wiring

— Field wiring must comply with local and

national fire, safety and electrical codes. Voltage to

unit must be within ± 10% of voltage indicated on

nameplate. Contact local power company for

correction of improper line voltage. ^

of

tim t tm

litie voltaic

coMti^tes ainm 813.4 h not

hy Omor

Wsrrsniy,

See Table 5 for recommended wire and fuse

size. When making electrical connections, provide

clearance at unit for refrigerant piping connections.

INSTALL A BRANCH CIRCUIT FUSED DIS

CONNECT of adequate size to handle unit starting

current. Locate disconnect within sight of and

readily accessible to the unit, per section 440-14 of

National Electrical Code (NEC).

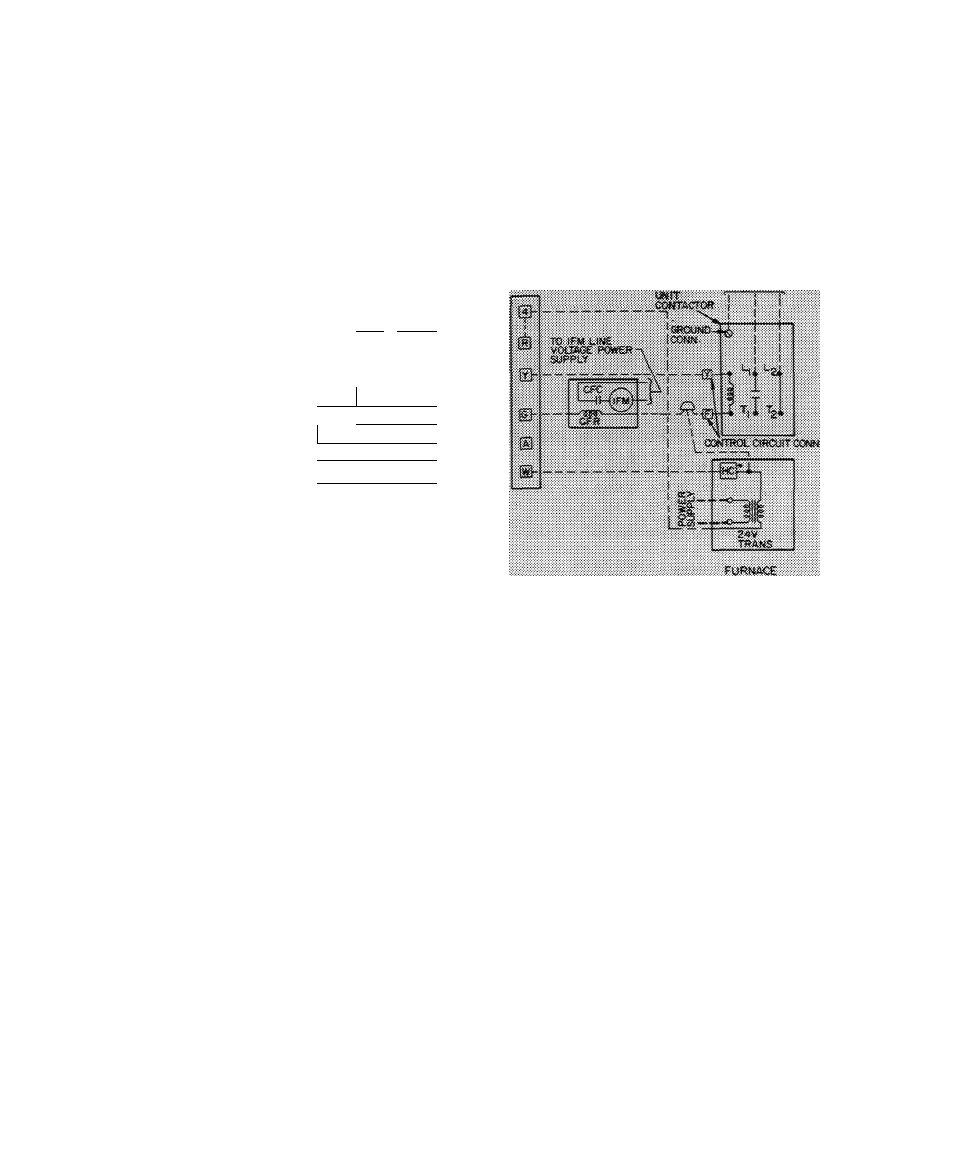

BRING LINE POWER LEADS INTO UNIT -

Extend leads from fused disconnect into unit thru

hole provided in service panel, Eig. 1 Connect

ground lead to ground lug in control box for

safety. Connect line power leads to contactor

screw terminals LI and L2. See Fig. 4. Contactor

terminals are approved for use with copper or

aluminum field wiring.

CONTROL POWER (24 v) — Use furnace or

fan-coil transformer as 24-v supply for system

Transformer must have a minimum capacity of 30

va. Bring control wiring thru hole in unit service

panel and connect to pigtails from unit contactor.

Contactor pigtails are labeled Y and F. Refer to

Fig. 4 for system control circuit connections.

CFC *- C/4

,f>i<

----------

r j - í V i C - . í

-

-i'-x

im

- ¡l’-i'-riiS r.íí '/(/"/>

<'''>».' w

w'......... . - w /

/,(. ■' ■' / !!'<■' I'.-i

''-i'

.

> Fig. 4 — Control Circuit Connections

^

START-UP

Energize crankcase heater (if so equipped) a

minimum of 24 hours before starting unit. To

energize heater only, turn the thermostat to “Off”

position and close electrical disconnect to con

densing unit.

Start Procedure

1. Backseat (open) liquid and suction line service

valves.

2. Set thermostat selector switch at “Off.”

3. Set room thermostat to desired temperature.

4.

Close electrical disconnects energizing entire

system.

5. Set room thermostat at “Cool” and fan switch

as desired (“Ean”) (“Auto.”). Operate unit for

15 minutes, then check system refrigerant

charge. See Refrigerant Charging.

r