Paratoie^ wilii oiergemsstier valve open – Carrier 38GK User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Motors and controls operate satisfactorily in a

range from 10% above to 10% below nominal unit

voltage (Table 5).

Do not connect charging hoses during initial

start procedure. (Loss of charge from this pro

cedure may result in capacity reduction.) If

necessary to add manifold gages for servicing, refer

to Carrier Standard Service Techniques Manual,

Chapter 1, page 1-5, Fig. 8, for bypass method of

returning charge to system.

REFRIGERANT CHARGING

38GK

condensing

units

contain

operating

charge for complete system when connected to

Carrier evaporators using 25 ft of accessory tubing.

Charge adjustment may be required on other

systems.

Checking Charge

1. Remove the valve stem caps from both service

valves and check the valve stems for the

backseat position (counterclockwise).

2. Remove the service port cap from both service

valves and attach a gage manifold. Purge the

gage manifold and hoses.

3.

Start the unit and allow it to run until

operating conditions stabilize and pressures

level out. To obtain pressure readings, the

service valve stems need only be turned clock

wise approximately one turn from the backseat

position.

4. Evaluate the system performance and the refrig

erant

charge

level as

in Chargemaster®

Operation section.

5. When the correct refrigerant charge level is

obtained, turn both service valves counter

clockwise. Remove the gage manifold.

6. Replace the valve stem and service port caps.

CHARGEMASTER OPERATION - Operate unit

10 minutes before using Chargemaster (Carrier Part

No. 38GC680004).

1. Tape Chargemaster feeler bulb to suction line

close to condensing unit. Insulate bulb. Ensure

suction line is clean for good contact with bulb.

2. Connect refrigerant drum to Chargemaster inlet

port with dmm in position for vapor charging.

3.

Connect Chargemaster outlet port to unit

suction valve service port.

4. Crack valves on refrigerant drum and Charge-

master to purge lines from drum to suction

valve. After purging lines, close valve on Charge-

master only.

5. Measure outdoor air dry-bulb temperature.

6. Crack unit suction valve and read evaporator

temperature at red needle position on Charge-

master temperature gage and suction line tem

perature at black needle position.

CACTIION: Do ooi read eva|)Oiaior

Um~

paratoie^ wilii Oiergemsstier valve open.

7. Enter Suction Line Temperature, Table 6, at

outdoor

air

temperature

(Step

5)

and

evaporator temperature (step 6). Find the

suction line temperature required for correct

system charge. If actual suction line tempera

ture (step 6) is higher than table value, the

system is undercharged. If suction line tempera

ture is lower than table value, the system is

overcharged.

Example-. At outdoor air temperature of 84 F

and evaporator temperature of 40 F, the system

will be correctly charged at 66 F (± 2 F)

suction line temperature.

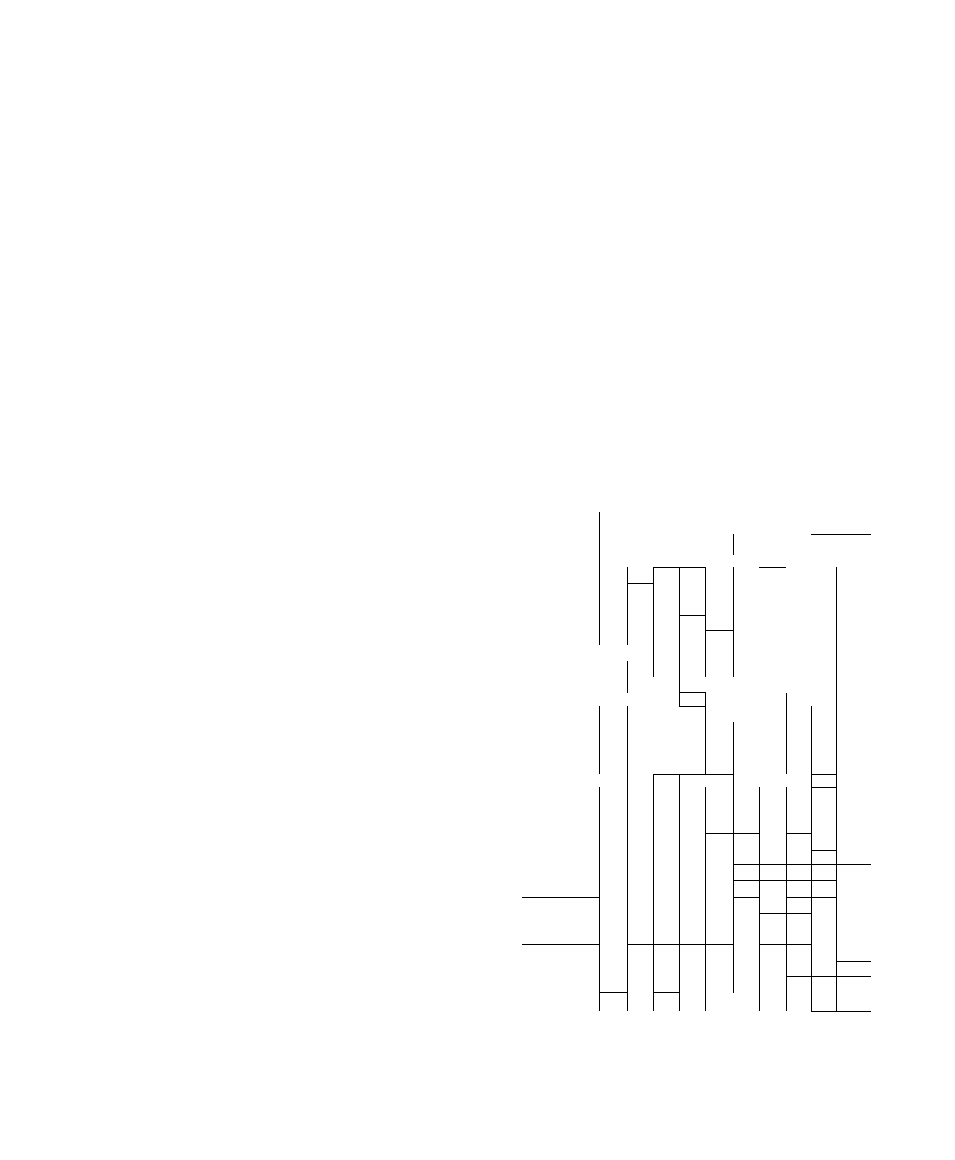

Table

6

— 38GK Chargemaster Charging Chart

(Capillary Tube or AccuRater Systems)

OUTDOOR

TEMP (F)

EVAPORATOR TEMP (F)*

^iJ

jj

I

m

J 7

. 4 3

4 5 L 4 8 _

Suction Line

1 emperature

6 0

32

4G

..

6 2

30 . 38 „49

6 4

28

37

47

60

_

6 6

27

35

45

57

If

6 8

34

43 1 54

67

,

7 0

32

41

52

64

7 2

1

31

39

50

61 j 72

7 4

30

37

48

58

69

7 6

29

36

46

56

ÓÓ

7 8

'"27

35

44

54 1 63

ill

8 0

8 2

_2%

illi

T3j

4^

321 40

52

50 "

61

”

59

"

a/

'W

.i

~80

—

- —

» 6

29

37

46

55

63

73

85

8 8

35

44

53

61

70

81

9 0

34

42

51

59

68

7S„ 90

9 2

33

41

49

57

65

75

86

9 4

39

47

55

63

72

83

9 6

38

45

53

61

70

80

9 8

36

44

51

59

67

77

1 0 0

42

49

57

65

75

1 0 2

41

48

55

63

73

1 0 4

39

46

53

61

70

1 0 6

45

51

59

68

1 0 8

43

49

65

n o

41

47

55

63

1 1 2

46

53

61

1 1 4

._ !..

50

59

Example

“Saturated evaporator temperature which is tlie equivalent tem

perature of pressure taken at the condensing unit suction service

valve