Viii. filter arrangement, A warning, A caution – Carrier 58DP User Manual

Page 8: B. automatic gas control valve, X. care and maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

remain open until the thermostat is satisfied.

When the thermostat is satisfied, it will deenergize the main

gas valve and stop the gas flow. The vent damper motor will

energize and close the damper. When the vent damper

reaches the full-closed position, the damper motor is

deenergized and will remain so until the next “call for heat”

by the thermostat.

C. Cooling (Cooling Models Only)

When the thermostat “calls for cooHng,” power from trans

former TRAN energizes the condensing unit contactor, cool

ing relay coil CFR, closing its contacts and energizing

blower motor MTR on its cooling speed. It continues to

operate until the thermostat is satisfied.

When the thermostat is satisfied, the circuit to terminal Gc

is broken, deenergizing cooling relay coil CFR which, in

turn, opens its contacts, stopping blower motor MTR.

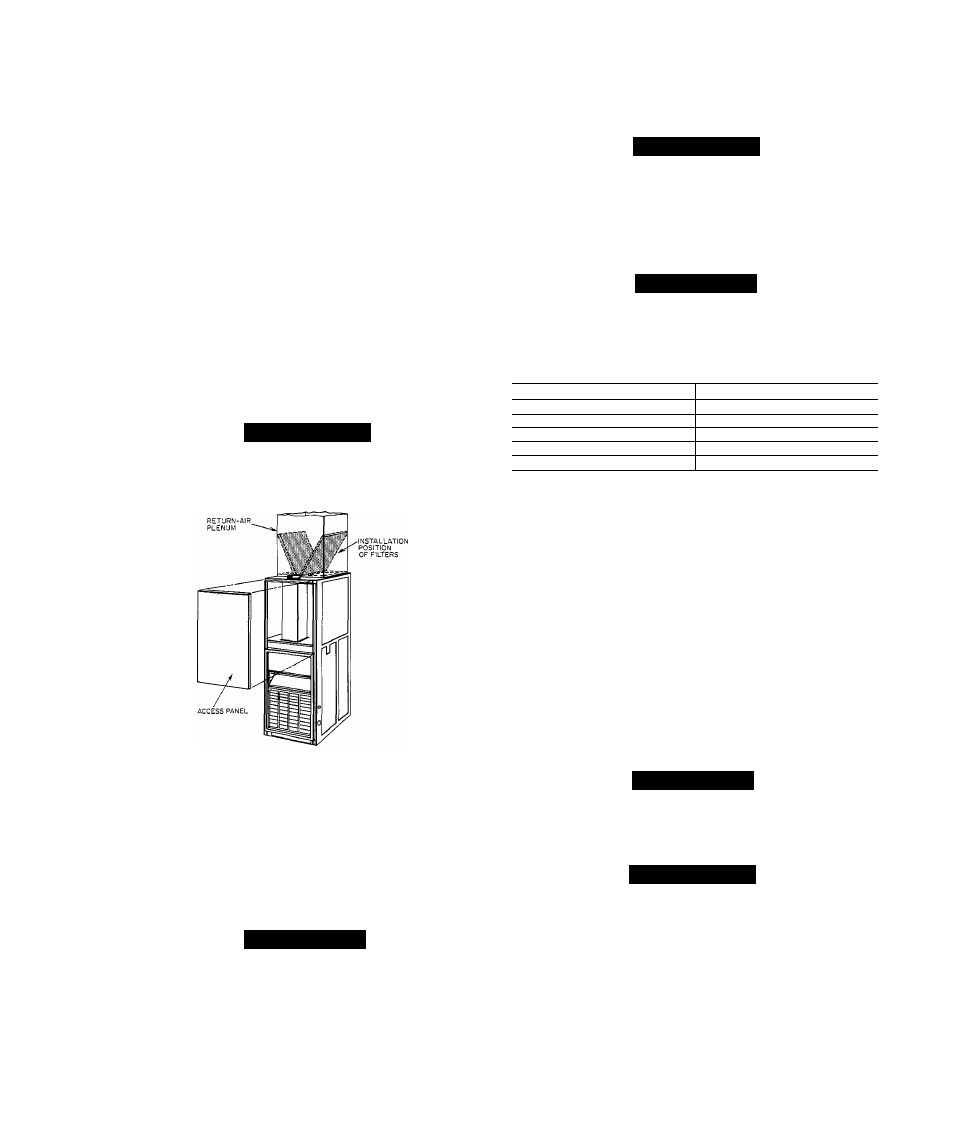

VIII. FILTER ARRANGEMENT

The two factory-supplied filters are shipped in the blower

compartment. After the return-air duct has been connected

to the furnace, install the filters in a V-formation inside the

retum-air plenum. See Fig. 12.

A WARNING

Never operate the unit without a filter or with the filter

access door removed. A failure to adhere to this warn

ing can cause a fire, physical injury, or death.

A78654

Fig. 12—Position of Filters

IX. STARTUP AND ADJUSTMENT

In addition to the following information, refer to “Proce

dures for Natural-Draft Gas-Fired Furnaces” packaged with

the unit.

NOTE:

There is a switch located in the blower compartment

that breaks the electrical power supply when the blower

access door is removed. Be sure the blower access door is

properly installed.

A CAUTION

This furnace is equipped with a fusible link in the vesti

bule area that wQl melt if an overheating condition

caused by an inadequate combustion-air supply or

improper venting practices develops. Do not jumper

this fuse. Correct the condition and replace the fuse

with an identical part.

NOTE:

The gas valve regulator has been nominally-set at

3.5 in. wc for natural gas. Refer to “Procedures for Natural-

Draft Gas Furnace Installation” for readjusting when

checking input.

A. Adjustment of Blower Speed

A WARNING

Disconnect the electrical power before changing the

speed tap. A failure to adhere to this warning can cause

personal injury.

To change motor speed taps, remove the motor tap lead (See

Table 5.) and relocate it on the desired terminal on the plug

in terminal block/speed selector located on the blower.

A CAUTION

When adjusting the blower speed, make certain that

the temperature rise across the heat exchanger does not

exceed that specified on the rating plate.

Table 5—Speed Selector

Speed

Tap No.*t

Common

C

Hi

1

Med-Hi

2

Med-Low

3

Low

4

♦Furnaces without a cooling fan relay are equipped with a 3-speed

motor.

fWhite wire from control box to common; black wire from control box

to cooling speed selection (when used); red wire from control box to

heating speed selection.

B. Automatic Gas Control Valve

These units are equipped with an automatic gas control

valve. If not already checked when lighting the main

burner, check the proper operation of this valve by moving

the room thermostat pointer above and below room temper

ature and observing that the meiin burners light on “call for

heat” and go off when the pointer is moved below room tem

perature setting.

NOTE:

For ease of adjusting the pilot flame, disconnect ter

minal No. 1 at the gas valve. This will prevent main burner

ignition and allow time to adjust the pilot. Reconnect the

power lead after adjustment.

X. CARE AND MAINTENANCE

A CAUTION

Because of possible damage to the equipment or per

sonal- injury, maintenance should be performed by qual

ified persons only.

The gas service pressure must not exceed 0.5 psig (14

in. wc).

A WARNING

Never store anything on, or in contact with, the fur

nace, such as:

1. Spray or aerosol cans, rags, brooms, dust mops,

vacuum cleaners, or other cleaning tools.

2. Soap powders, bleaches, weixes or other cleaning

compounds, plastic or plastic containers, gasoline,

kerosene, cigarette lighter fluid, dry cleaning fluids,

or other volatile fluids.

3. Paint thinners and other painting compounds,

paper bags or other paper products.

A failure to adhere to this warning can cause corrosion

of the heat exchanger and vent system, fire, personal

injmy, or death.

-

7

—