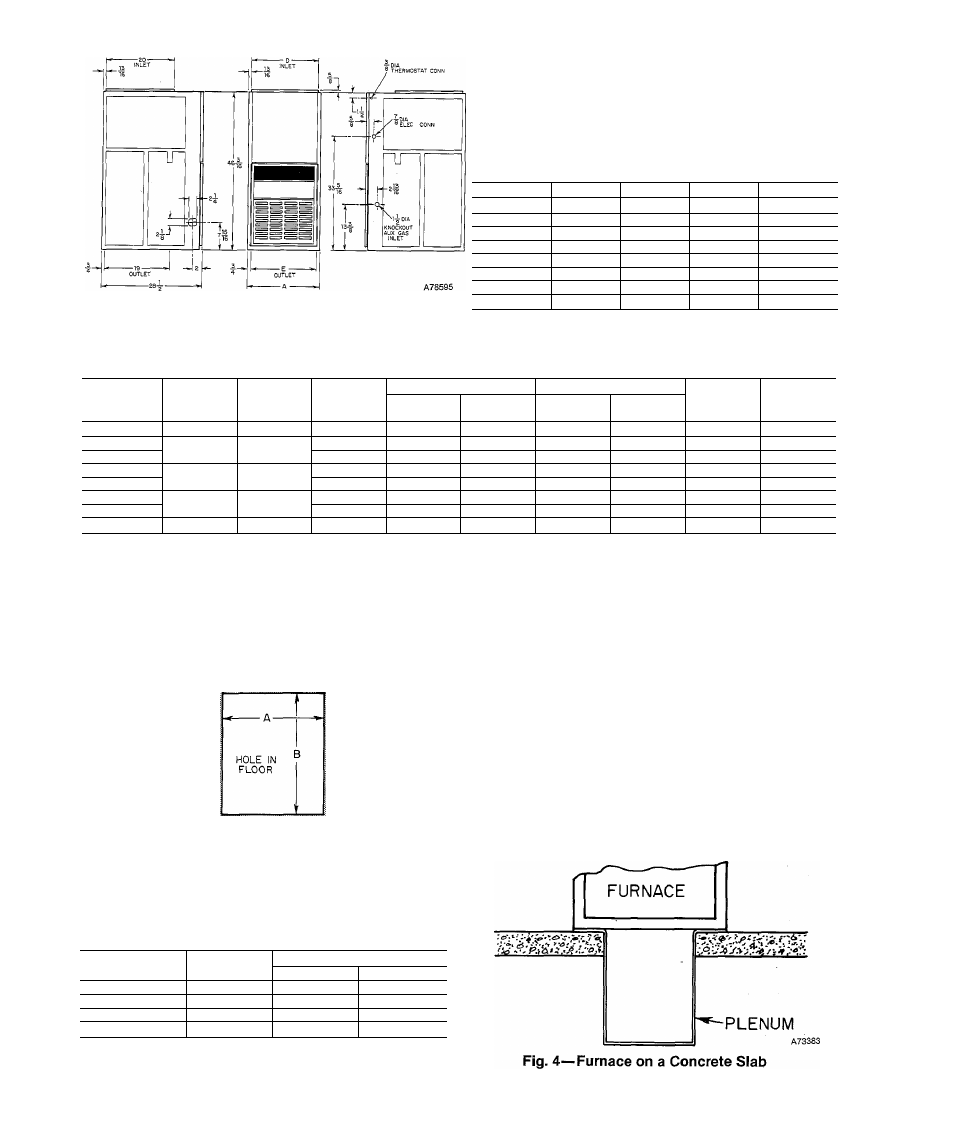

Fig. 2—dimensionai drawing – Carrier 58DP User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 2—Dimensions (in Inches)

Size

Vent

050-BA

14^16

12^,6

12-’-’/i6

4

075-AA

M'h

15%

16

4

075-BA

M'k

157s

16

4

100-AA

17’¿

15%

16

5

100-BA

177^

15%

16

5

125-AA

21

19%

19%

5

125-BA

21

19%

19%

5

150-BA

24’¿

22'%s

23

6

Fig. 2—Dimensionai Drawing

Table 3—Ratings and Performance*

Size

Input

Btuh

Capacity

Btuht

Temp

Rise

Range

Heating

Cooling

Motor

HP&

Type

Approx

Shipping

Weight

Ext Static

Pressure

CFM

Ext Static

Pressure

CFM

050-BA

50,000

39,000f

45—75

0.50

600

0.5

800

%-SP

129

075-AA

75,000

58,000

70—100

0.12

630

—

—

7io-SP

148

075-BA

45—75

0.50

895

0.5

1255

%-SP

157

100-AA

100,000

78,000t

70—100

0.20

850

—

%-SP

163

100-BA

60—90

0.50

960

0.5

1630

%-PSC

170

125-AA

125,000

97,000f

70—100

0.20

1050

—

—

'h-SP

187

125-AA

60—90

0.50

1195

0.5

1620

'k-PSC

187

150-BA

150,000

116,000f

55—85

0.50

1535

0.5

2075

%-PSC

227

*The above ratings are certified for aititudes to 2000 ft. For elevators above 2000 ft, reduce ratings 4% for each 1000 ft above sea level. Refer to'

National Fuel Gas Code Table F4.

fDetermined by U.S. Government tests.

ijrDeduct 1000 Btuh for Model 58DR.

2. Construct hole in floor per dimensions in Fig. 3 and

Table 4.

3. Place plenum and furnace as shown in Fig. 4.

B. Installation on a combustible floor

1. Read Installation Instructions packaged with acces

sory combustible floor base.

2. Cut and frame hole in floor per dimensions hsted in

Installation Instructions packaged with combustible

floor base. If this requires cutting of a floor joist, tie

ends of cut joist into adjacent joists so that proper

floor support win be maintained.

3. Assemble and install combustible floor base per

instructions packaged with base.

4. When completed, combustible floor base, plenum, and

furnace (or coü casing when used) should be installed as

shown in Fig. 6.

A73382

Fig. 3—Floor Opening for

Concrete Slab

Table 4—Opening Dimensions

Furnace Casing

A

B

Width

Heat-Only

Heat/Cool*

14%6

13%

19%

19%6

17%

16%6

19%

19%s

21

19%

19%

19%6

24%

23%6

19%

19%6

♦These dimensions apply when a Model 28RC or RD Evaporator Coil

casing is to be installed.

—

2

—