A warning, D. pilot – Carrier 58DP User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

9. Units with motor capacitor, loosen screw in strap hold

ing capacitor to blower housing and slide capacitor

from under strap.

10. Mark blower wheel, motor, and motor support in rela

tion to blower housing before disassembly, to insure

proper reassembly.

11. Loosen setscrew holding blower wheel onto motor

shaft.

12. Remove bolts holding motor mount to blower housing

and slide motor and mount out of housing. Some

motors have a ground wire attached to blower housing;

disconnect it also.

13. Lubricate motor.

a. Remove dust caps or plugs from oU ports located at

each end of motor.

b. Use good grade of SAE 20 nondetergent motor oU

and put one teaspoon, 5cc, 3/16 oz., or 16 to 25

drops in each oil port.

c. Allow tune for total quantity of oil to be absorbed

by each bearing.

d. After oiling motor, be sure to wipe excess oil from

motor housing.

e. Replace dust caps or plugs on oil ports.

14. Remove blower wheel from housing.

a. Mark blower wheel orientation and cutoff location

to insure proper reassembly.

b. Remove screws holding cutoff plate and remove cut

off plate from housing.

c. Lift blower wheel from housing through opening.

15. Clean blower wheel and motor by using vacuum with

soft brush attachment. Care must be exercised not to

disturb balance weights (clips) on blower wheel vanes.

Also do not drop or bend wheel, as balance will be

affected.

16. Reassemble blower by reversing procedures 14a thru

14c. Be sure wheel is positioned for proper rotation.

17. Reassemble motor and blower by reversing procedures

8 thru 12. If motor has ground wire, be sure it is con

nected as before. Be sure the blower wheel setscrew is

on the flat of the motor shaft when tightening the

setscrew.

18. Reinstall blower assembly in furnace.

19. Reinstall vent enclosure back.

20. Reinstall vent pipe through opening in top plate, secure

to drafthood and connect remainder of vent pipe

assembly.

21. Reinstall vent enclosure front, and secure with screw.

22. Reinstall access panel.

C. Cleaning Heat Exchanger

If it becomes necessary to clean the heat exchanger because

of carbon deposits, soot, etc., proceed as follows:

1. Turn off gas and electrical supply to furnace.

2. Remove front access doors.

3. Remove vent pipe enclosure front and flue pipe.

4. Remove draft diverter. Screws are located inside draft

diverter opening.

5. Remove flue baffles from flue outlets of heat

exchanger.

A79080

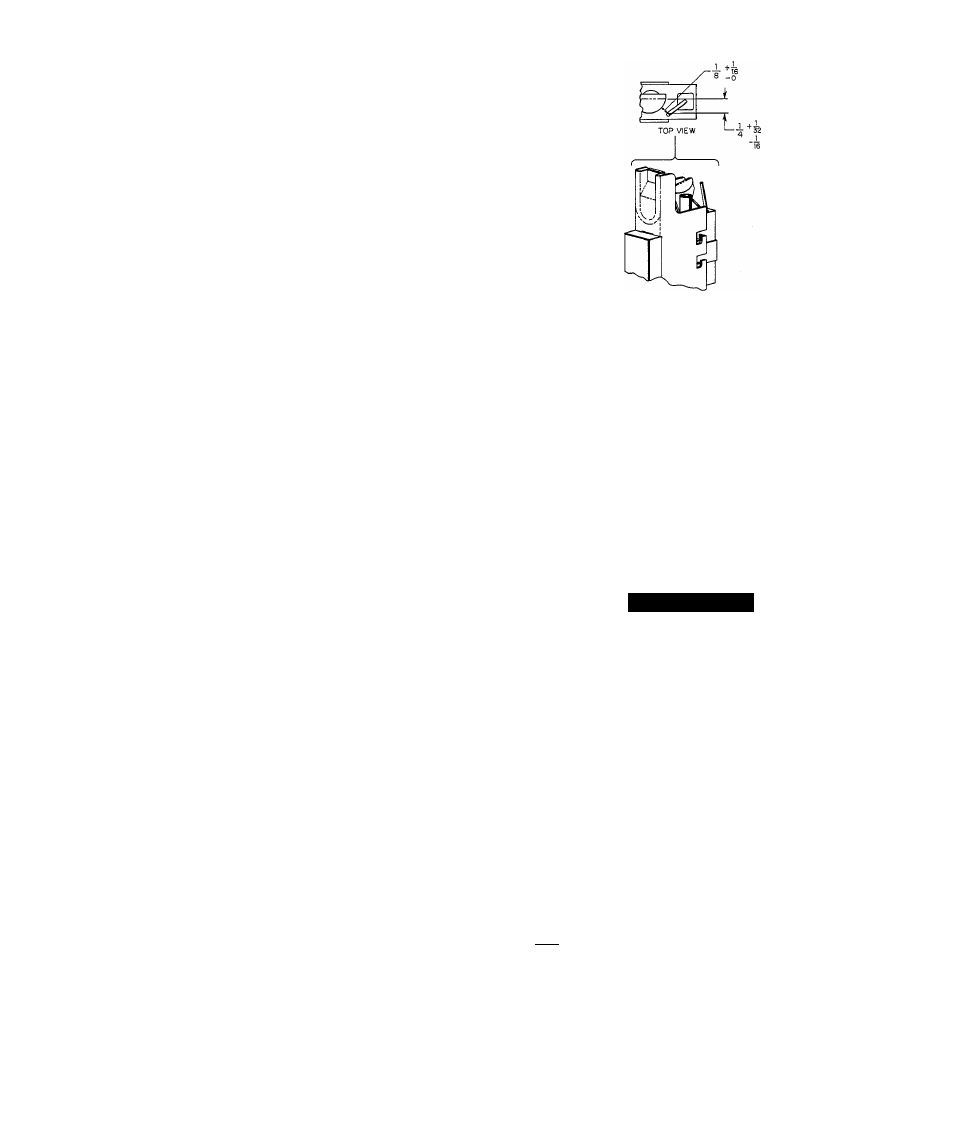

Fig. 16—Position of Electrode to Pilot

6. Remove secondary-air shield and burners. To remove

pilot burner, disconnect pilot supply tube (and thermo

couple on 100% shut-off models) at gas valve.

7. Clean flue ways writh brush and or vacuum. Check heat

exchanger for leaks and cracks. Replace if necessary.

8. Replace flue baffles. Be sure aU screws are in place emd

tight.

9. Replace draft diverter and vent connector. Be sure

screws are replaced and tight.

10. Using vacuum cleaner wdth soft brush attachment,

clean burners. After cleaning, replace burners and

secondary-air shield.

11. Turn on gas and electricity. Check for gas leaks.

A WARNING

Never use a match or other open flame to check for gas

leaks. Use a soap-and-water solution. A failure to

adhere to this warning can cause an explosion, fire, per

sonal injury, or death.

D. Pilot

Check the pilot and clean if necessary at the beginning of

each heating season. The pilot flame should be high enough

for proper inipingement of the safety element and to light

the burners. Remove the accvunulation of soot and carbon

from the thermocouple safety element or sensing probe.

E. Electrical Controls and Wiring

NOTE:

There may be more them one electrical supply to

unit.

With power disconnected to unit, check aU electrical connec

tions for tightness. Tighten any screws or electrical connec

tions. If any smoky or burned connections are noticed, dis

assemble the connection, clean all parts, and stripped wore,

and reassemble properly and securely. Electrical controls

are difficult to check without proper instrumentation; there

fore, reconnect electrical power to unit and observe unit

through one complete operating cycle. If there are any dis

crepancies in the operating cycle, contact your Dealer and

request service.

-

9

—