Wilkerson V29 User Manual

Warning

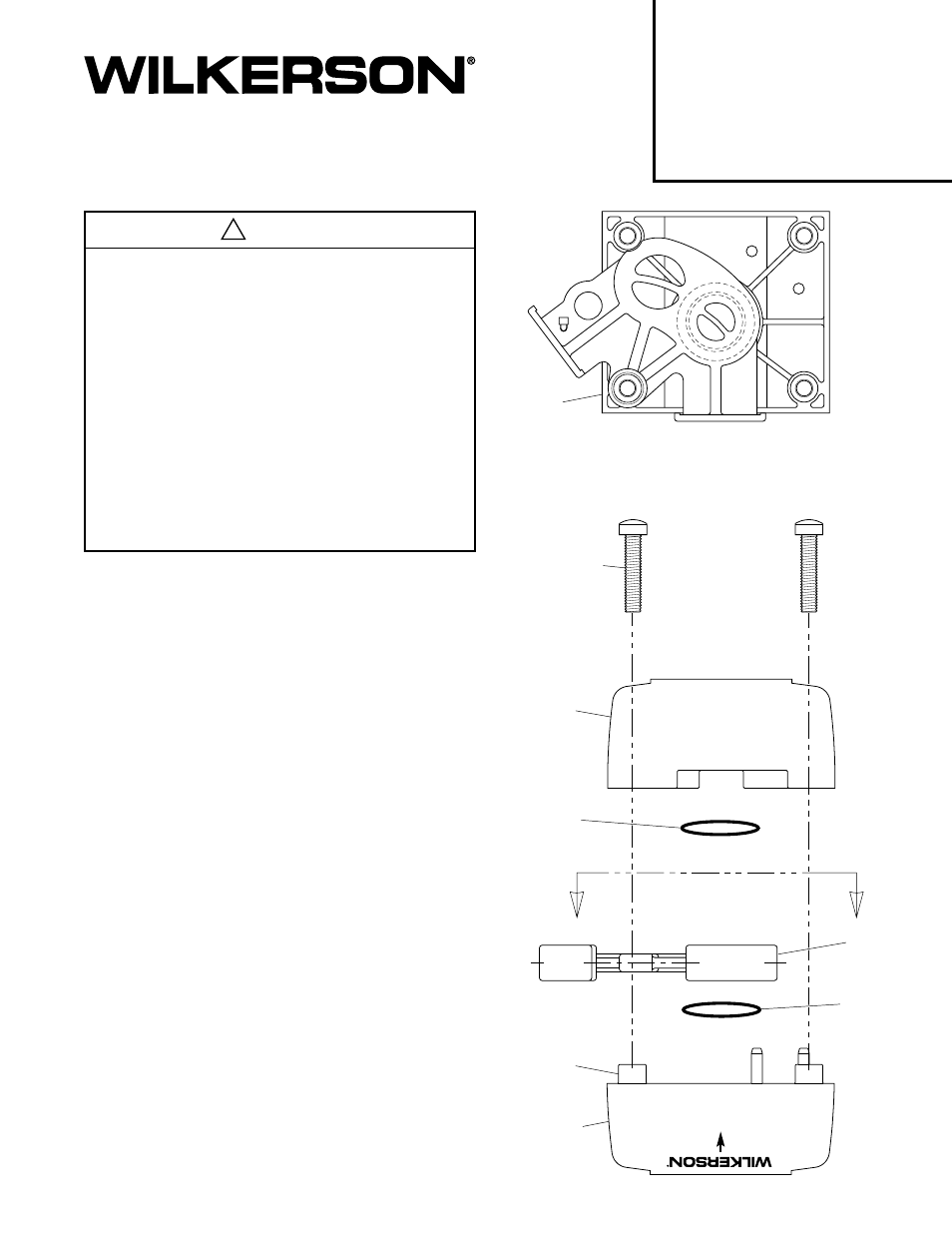

PUSH

TO

CLOSE

PUSH

TO

OPEN

OUTLET

DETAIL

OF PIVOT

PIN

SELF-TAPPING

SCREWS

INLET

BODY

PIVOT

PIN

OUTLET

BODY

O-RING

O-RING

SHUT

OFF

BLADE

INSTALLATION

1. Refer to Warnings prior to installation.

2. Install as close to the point of use as possible.

3. Unit must be installed with the flow in the direction of the flow arrow

on top of the body.

4. Avoid using reducing bushings, couplings, etc., whenever possible

to install this product. These devices restrict air flow and can affect

performance.

5. Maximum pressure rating is 150 psig (10.3 bar). Temperature

range is 32°F to 150°F (0°C to 65.5°C)

6. Unit can be locked in the closed position using a standard padlock.

MAINTENANCE

THE UNIT MUST BE REMOVED FROM THE COMPRESSED AIR LINE.

1. Remove retaining screws, and separate body halves.

2. Remove shut off blade.

3. Remove o-rings from body halves.

4. Lightly lubricate o-rings with Magnalube-G or equivalent and place

in grooves on body halves.

5. Align shut off blade on pivot pin located on outlet body half as shown.

6. Place body halves together and tighten screws to approximately

20 in/lbs.

Richland, MI 49083

Tel: (269) 629-5000

Installation & Service Instructions

83-543-000

Safety Lockout Valve

Models V19 and V29

ISSUED: February, 2005

Supersedes: August, 2002

Doc. #83-543-000, Rev. 2

WARNING

To avoid unpredictable system behavior that can cause personal injury

and property damage:

•

Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

•

Disconnect air supply and depressurize all air lines connected to

this product before installation, servicing, or conversion.

•

Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

•

Medium must be moisture-free if ambient temperature is below

freezing.

•

Service according to procedures listed in these instructions.

•

Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

•

After installation, servicing, or conversion, air and electrical supplies

(when necessary) should be connected and the product tested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

•

Warnings and specifications on the product should not be covered

by paint, etc. If masking is not possible, contact your local

representative for replacement labels.

!