Service kits available, Service, Servicing filter element – Wilkerson BB3 User Manual

Page 2: Servicing regulator

BB3 Brass Filter / Regulator Series

84-037-000

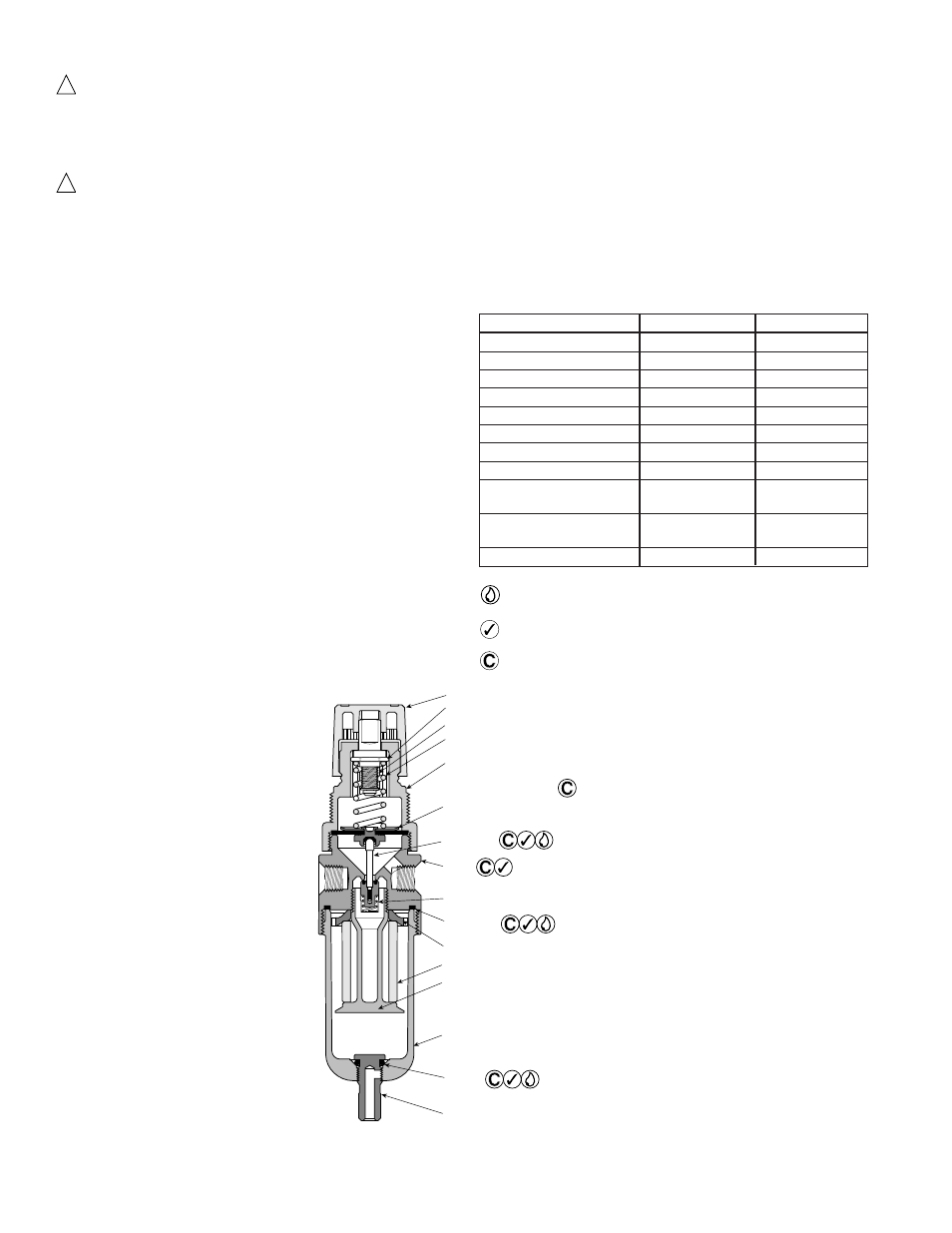

Figure 1

BB3 Filter / Regulator

Servicing Filter Element -

(Refer to Figure 1)

1. Unscrew and remove bowl.

2. Unscrew the filter holder from body and then remove element.

3. Clean all internal parts and bowl before reassembling.

4. Install new element. IMPORTANT: The Filter / Regulator will not

operate properly if the deflector is not installed properly. The deflector

must be installed between the filter stem and the filter body.

5. Attach filter holder and finger tighten firmly.

6. Replace bowl seal. Lightly lubricate new seal to assist with retaining

it in position.

7. Install bowl into body and tighten; hand tight, plus 1/4 turn.

Servicing Regulator -

(Refer to Figure 1)

1A. On BB3, disengage the adjusting knob by pulling upward. Turn

adjusting knob counterclockwise until the compression is released

from the pressure control spring.

1B. On BB3 with tamper resistant control, do not adjust setting.

2. Remove the bonnet and bowl assemblies by unscrewing the bonnet

and bowl from the body.

3. Remove diaphragm assembly from bonnet assembly.

4. Remove filter stem, filter element, poppet assembly, poppet return

spring.

Service Kits Available

Description

w/ Plastic Bowl

w/ Metal Bowl

Automatic Drain

GRP-96-813

GRP-96-813

Manual Drain

GRP-96-812

GRP-96-812

Element (5 Micron)

FRP-96-806

FRP-96-806

Bowl, Manual Drain

GRP-96-808

GRP-96-810

Bowl, Piston Drain

GRP-86-809

GRP-96-811

Gauge 0-160 PSI

GRP-95-227

GRP-95-227

Gauge 0-60 PSI

GRP-95-228

GRP-95-228

Tamper Resistant Kit

RRP-96-822

RRP-96-822

Regulator Repair Kit

(Relieving)

RRP-96-819

RRP-96-819

Regulator Repair Kit

(Non-Relieving)

RRP-96-820

RRP-96-820

Sight Glass

RRP-96-823

RRP-96-823

Service

Caution: Disconnect or shut off air supply and exhaust the

primary and secondary pressures before servicing unit.

Turning the adjusting knob counterclockwise does not vent

downstream pressure on non-relieving regulators.

Downstream pressure must be vented before servicing

regulator.

Caution: Do not use synthetic oils such as esters. Do not use

silicones.

Note: After servicing unit, turn on air supply and adjust regulator

to the desired downstream pressure. Check unit for leaks. If

leakage occurs, do not operate - conduct repairs and retest.

!

!

5. Clean and carefully inspect parts for wear or damage.

If replacement is necessary, use parts from service kits. Clean

bowl.

6. Lubricate o-rings with grease found in service kits.

7. Install poppet return spring, poppet assembly, and filter holder.

IMPORTANT: The Filter / Regulator will not operate properly if

the defector is not installed properly. The deflector must be

installed between the filter stem and filter body.

8. Install filter element and firmly tighten baffle onto the filter stem.

9. Install diaphragm assembly into body assembly. Assemble

bonnet assembly onto body and tighten per Figure 1.

10. Install bowl into body and tighten, hand tight, plus 1/4 turn.

Knob

Bonnet - Torque:

4.5 to 5.6 Nm (60 to 70 in.lb.)

Adjusting Screw

Drive Nut

Control Spring

Spring,

Poppet Return

Diaphragm Assembly

(Includes Upper Diaphragm Plate

& Lower Diaphragm Plate

Poppet

Assembly

Body

Filter Holder

(Hand Tighten)

Element

Deflector

O-Ring

Bowl Seal

Manual Drain

(Finger Tighten)

Bowl

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface imperfections. If present,

reduced service life is probable and future replacement should be

planned.

Clean with lint-free cloth.