Operation and service – Wilkerson SL2 User Manual

Page 2

SL2 Mist Lubricators

83-950-000

By counting the number of drops per minute in the sight dome,

you can adjust to your requirements.

Every drop visible in the sight dome goes downstream.

Generally, one drop per minute downstream for every

10 - 15 SCFM flow is satisfactory.

25 drops per minute equals one (1) ounce per hour - volume

of oil passing through the sight dome.

NOTE: This is a constant density type lubricator which

delivers a constant ratio of oil to air flow. Therefore, if air

flow increases or decreases, oil delivery will be

adjusted propor tionately. ONLY IF A DIFFERENT

RATIO IS DESIRED SHOULD YOUR ADJUSTMENT KNOB

SETTING BE CHANGED AFTER YOUR INITIAL SETTING.

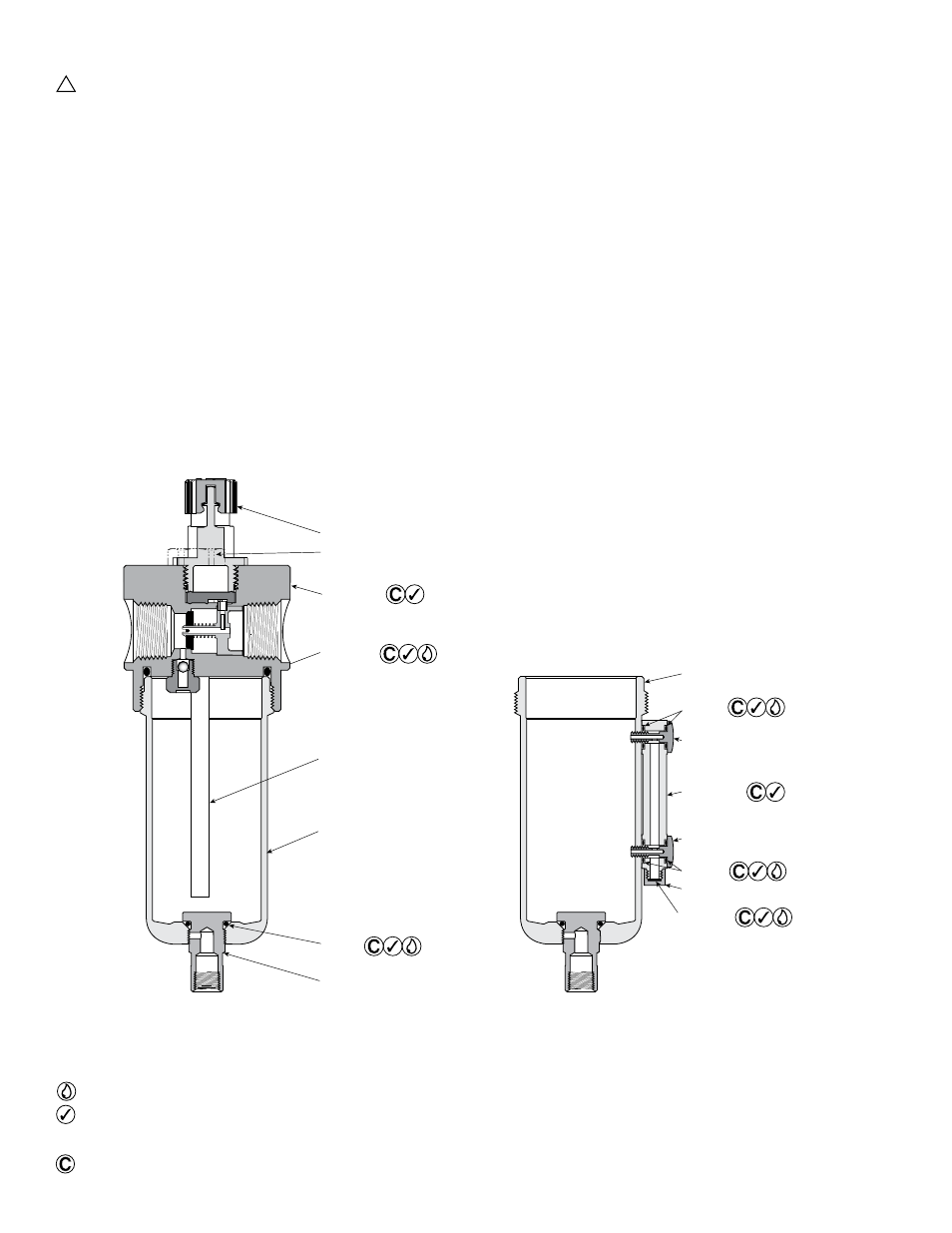

4. To replace fill plug, drip control, & service lubricator:

A. Turn off air supply and depressurize the unit.

B. Refer to pictorial for servicing and torque values.

C. Turn on air supply and check lubricator for leakage. If

leakage occurs,

DO NOT OPERATE — conduct repairs

again.

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface imperfections.

If present, reduced service life is probable and future replacement

should be planned.

Clean with lint-free cloth.

Fill Tube

O-Ring

Bowl Seal

Manual Drain

(Finger Tighten)

Bowl

(Hand Tighten)

Lubricator

Body

Drip Control

Fill Plug

Torque: 1.2 to 1.7 Nm

(11 to 15 in. lb.)

}

O-Rings

Bowl

Hand Tight

O-Rings

Seal Cap

Finger Tight

Cap Seal

Screw

Torque .56 to 1.13 Nm

(5 to 10 in. lb.)

Screw

Torque .56 to 1.13 Nm

(5 to 10 in. lb.)

Sight Glass

SL2 Metal Bowl

with Sight Gauge

Operation and Service

Caution: Shut off air supply and exhaust the pressure

trapped within the lubricator before filling unit.

1. Remove the fill plug and fill the lubricator with the suggested

lubricant.

Suggested lubricant: F442

Petroleum based oil of 100 to 200 SSU viscosity at 100°F and

an aniline point greater than 200°F. (Mobil DTE24 and Sun

Company Sunvis 932 are good examples). Do not use oils

with adhesives, compound oils containing solvents, graphite,

detergents or synthetic oils.

2. Replace the fill plug (by turning clockwise) and seat firmly.

Excessive torque is not required. If leakage occurs,

DO NOT

OPERATE — check to make sure the fill plug is installed

properly. The lubricator is now ready for setting.

3. Oil delivery adjustment — To adjust oil delivery, turn adjustment

knob on top of the lubricator.

Leaner — Clockwise

Richer — Counterclockwise

!