Wilkerson L50 User Manual

Page 2

INSTALLATION

1.Refer to the warning on front page.

2.Install as close as possible to the equipment requiring lubrication.

3.Install the unit with the air moving through the body in the direction indi-

cated by the arrow.

4.Install a unit with the same pipe size as the line in use. Avoid using

fittings, couplings, etc., that restrict the airflow or baffle the oil out of the

air at the lubricator outlet.

5.The unit may be filled under pressure by removing the fill plug and

pouring the oil through the fill port. The bowl may be taken off after the fill

plug is removed if a more rapid fill is required.

DO NOT

replace the fill

plug until the bowl and bowl guard are in position and the clamp ring is

locked in place.

N O T E :

As the fill plug is removed, the air pressure in

the bowl will be released.

6.Use only clean nondetergent oil. SAE 10 or lighter is usually best.

7.The rate of oil delivery may be controlled by turning the adjusting screw

counterclockwise for more and clockwise for less oil delivery. This

lubricator delivers all the oil downstream which passes through the sight

dome. The oil delivery rate will change automatically to deliver more oil

during higher airflows and less oil for airflows lower than that at which

the original setting was made.

8.Maximum pressure and temperature ratings for transparent plastic bowls

are 150 psig (10,3 bar) and 125°F (52°C), and for metal bowls, 200 psig

(14 bar) and 175°F (79.4°C).

MAINTENANCE

1. Given clean opera ting condition s, t his un it w ill be troub le- fr ee .

Contaminants from dirty oil may collect on the siphon tube inlet filter,

requiring the filter to be cleaned by tapping on a hard surface and

blowing off with an air blow gun.

2. If the oil delivery rate drops, the lubricator should be cleaned. Shut off air

supply and reduce pressure in unit to zero. Remove the Flow-Guide®

variable orifice screw and clean its air passage with a small wire. Check

the bore that the screw fits into for contaminants and clean, if necessary.

Be sure that the passageway from the sight dome cavity into the Flow-

Guide® variable orifice post is open. Remove the adjusting screw and

clean the needle and the seat in the body. Inspect and clean the

passage from the needle seat down into the adapter.

3. Drain off any contaminants which collect in the bottom of the bowl.

4. Lubricate o-rings with Parker O-Lube before assembly.

5. Clean plastic bowl with a clean, dry cloth only.

KITS AND REPLACEMENT PARTS

Repair Kit - O-Rings...............................................................LRP-95-060

Bowl O-Ring Kit .....................................................................GRP-95-256

Sight Dome Kit ......................................................................LRP-95-249

Siphon Tube Assembly Kit.....................................................LRP-96-182

Fill Plug Kit .............................................................................LRP-95-250

Flow-Guide® Variable Orifice Kit ...........................................LRP-95-252

Bowl Assembly Kit (No Guard) ..............................................LRP-96-160

Bowl Guard ...........................................................................GRP-95-808

Plastic Bowl w/Plastic Petcock

and Bowl Guard ...................................................................LRP-95-830

Plastic Petcock Kit .................................................................LRP-95-181

Metal Gauge Bowl w/Petcock ...............................................GRP-95-676

Check Ball and O-Ring Kit .....................................................LRP-95-310

ACCESSORIES

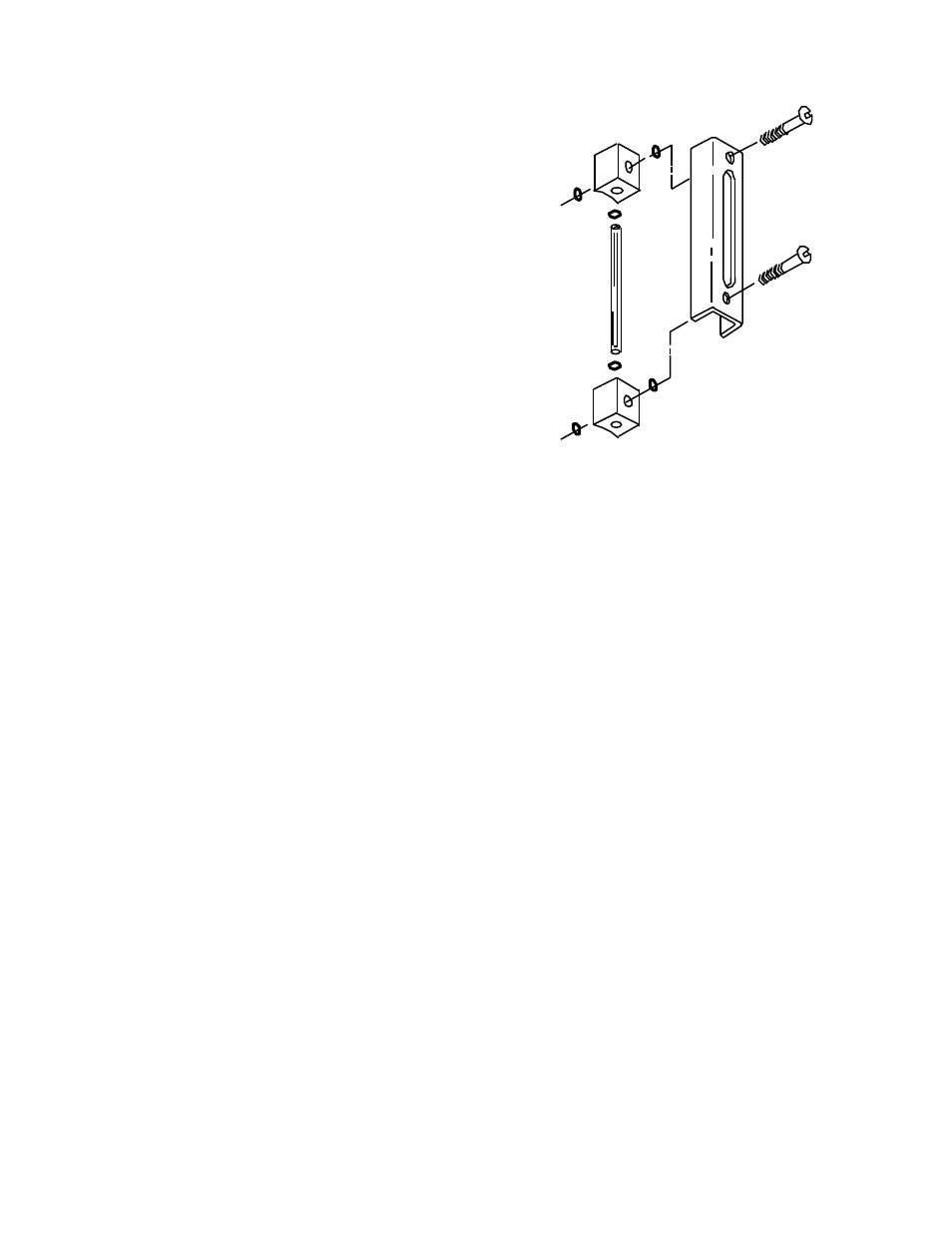

Sight Gauge Kit .....................................................................LRP-95-771

Tamper Resistant Kit ...........................................................LRP-95-587

Force Fill Adapter..................................................................LRP-96-420

SIGHT GAUGE KIT