Wilkerson L34 User Manual

Installation and maintenance sheet, Atomist, Warning

INSTALLATION

1. Refer to caution above.

CAUTION! DEPRESSURIZE BEFORE SERVICING!

2. Install as close as possible to the equipment requiring lubrication.

3. Install the unit with the air flowing through the body in the direction indicated

by the arrow.

4. Install the same pipe-size unit as the pipeline in use.

5. CAUTION! L34 AtoMist

™

Style lubricators CANNOT be filled while unit is

under pressure. MAKE SURE UNIT IS TURNED OFF AND DEPRESSURIZED

BEFORE REMOVING FILL PLUG. Remove fill plug and fill unit. Use only

clean oil, SAE 10 or lighter is best. DO NOT REPRESSURIZE UNIT unless

fill plug, bowl, and bowl guard are in position and the bowl clamp ring is

securely locked in place.

6. The rate of oil delivery can be controlled by turning the adjusting screw

counterclockwise for more oil and clockwise for less oil delivered. To adjust

this type of lubricator, first reduce the airflow to the airflow to minimum

scfm requirement, then set the oil drip rate so the desired amount of oil is

delivered to the point of use. The more the airflow increases, the more oil

you will need, and the you will automatically receive. Ordinarily, adjust

lubricator so that, for every 33 scfm of air being used. one drop of oil per

minute passes through the sight dome; e.g., for 165 scfm, adjust for five

drops per minute; 330 scfm, 10 drops per minute, etc.

7. DO NOT OVERFILL BOWL; OIL LEVEL MUST REMAIN BELOW

CLASSIFIER; UNIT WILL NOT FUNCTION IF OVERFILLED.

8. Maximum pressure and temperature ratings are: 150 psig (10,3 bar) and

125°F (55°C) for units with transparent plastic bowls and 200 psig (13,8

bar) and 175°F (79°C) for units with metal bowls.

MAINTENANCE

1. The lubricator should remain trouble-free given clean operating conditions.

Contaminants from dirty oil can collect on bottom of bowl or on siphon tube

inlet filter. After tapping filter or bowl on a hard surface, use an air gun to blow

out residual dirt.

2. IF OIL DELIVERY RATE DROPS, clean lubricator. Shut off air supply and

reduce pressure inside lubricator to zero. Remove adjusting screw, clean

needle and seat in body. Inspect and clean passage from needle seat down

into siphon tube adapter.

3. OIL NOT SPRAYING ONTO RECLASSIFIER. Mist generator may be

plugged. Turn off air supply and remove fill plug to vent unit. Remove bowl,

bowl guard and clamp ring. Disassemble reclassifier and, using a screwdriver,

pry out misting nozzle and clean dirt from holes. Reassemble unit. DO NOT

PRESSURIZE UNIT until fill plug, bowl, and bowl guard are in position and

clamp ring is securely locked in place.

4. Drain off contaminants that collect in bottom of bowl.

83-298-000 9/97

Printed in U.S.A.

INSTALLATION AND

MAINTENANCE SHEET

AtoMist

™

Lubricator Model L34

with Variations and Accessories

DO NOT PLACE PLASTIC BOWL UNIT IN SERVICE

WITHOUT METAL BOWL GUARD INSTALLED.

Plastic bowl units are sold only with metal bowl guards. To minimize the danger of flying

fragments in the event of plastic bowl failure, the metal bowl guards should not be

removed. If the unit is in service without the metal bowl guard installed, manufacturer’s

warranties are void, and the manufacturer assumes no responsibility of, any resulting

loss.

IF UNIT HAS BEEN IN SERVICE AND DOES NOT HAVE A METAL BOWL GUARD,

ORDER ONE AND INSTALL BEFORE PLACING BACK IN SERVICE.

CAUTION

Certain compressor oils chemicals, household cleaners, solvents, paints and fumes will

attack plastic bowls and can cause bowl failure. Do not use near these materials. When

bowl becomes dirty replace bowl or wipe only with a clean, dry cloth. Reinstall metal

bowl guard or buy and install a metal bowl guard. Immediately replace any crazed,

cracked, damaged or deteriorated plastic bowl with a metal bowl or a new plastic bowl

and a metal bowl guard.

WE CANNOT POSSIBLY LIST ALL HARMFUL SUBSTANCES. SO CHECK WITH A

MOBAY CHEMICAL OR GENERAL ELECTRIC OFFICE FOR FURTHER INFORMA-

TION ON POLYCARBONATE PLASTIC.

Except as otherwise specified by the manufacturer, this product is specifically designed

for compressed air service, and used with any other fluid (liquid or gas) is a misapplica-

tion. For example, use with or injection of certain hazardous liquids or gases in the sys-

tem (such as alcohol or liquid petroleum gas) could be harmful to the unit or result in a

combustible condition or hazardous external leakage. Manufacturers warranties are void

in the event of misapplication, and manufacturer assumes no responsibility for any

resulting loss. Before using with fluids other than air, or for non-industrial applications, or

for life support systems consult manufacturer for written approval.

®

OPERATIONS

REPAIR KITS AND REPLACEMENT PARTS

O-Ring Repair Kit................................................................................LRP-95-058

Bowl Assembly — no guard ...............................................................LRP-96-160

Siphon Tube Assembly Kit..................................................................LRP-96-182

Flow Guide® Variable Orifice Kit (3/4" models)..................................LRP-95-244

Flow Guide® Variable Orifice Kit (1 " models)....................................LRP-95-245

Sight Dome Kit ....................................................................................LRP-95-249

Fill Plug Kit ..........................................................................................LRP-95-253

O-Ring Kit for Adjusting Screw...........................................................GRP-95-255

Bowl O-Ring Kit ..................................................................................GRP-95-256

Force-fill Adapter ................................................................................GRP-96-394

Clamp Ring Assembly........................................................................GRP-96-404

Tamper-resistant Kit ...........................................................................LRP-95-587

AtoMist® Lubricator Generator Assembly ..........................................LRP-95-675

Metal Gauge Bowl with Petcock ........................................................GRP-95-676

Sight Gauge Kit...................................................................................LRP-95-771

Bowl Guard.........................................................................................GRP-95-808

Plastic Bowl with Plastic Petcock and Bowl Guard ............................LRP-95-830

Plastic Bowl — no drain......................................................................LRP-96-940

Check Ball and O-Ring Kit ..................................................................LRP-95-310

WARNING

!

!

!

!

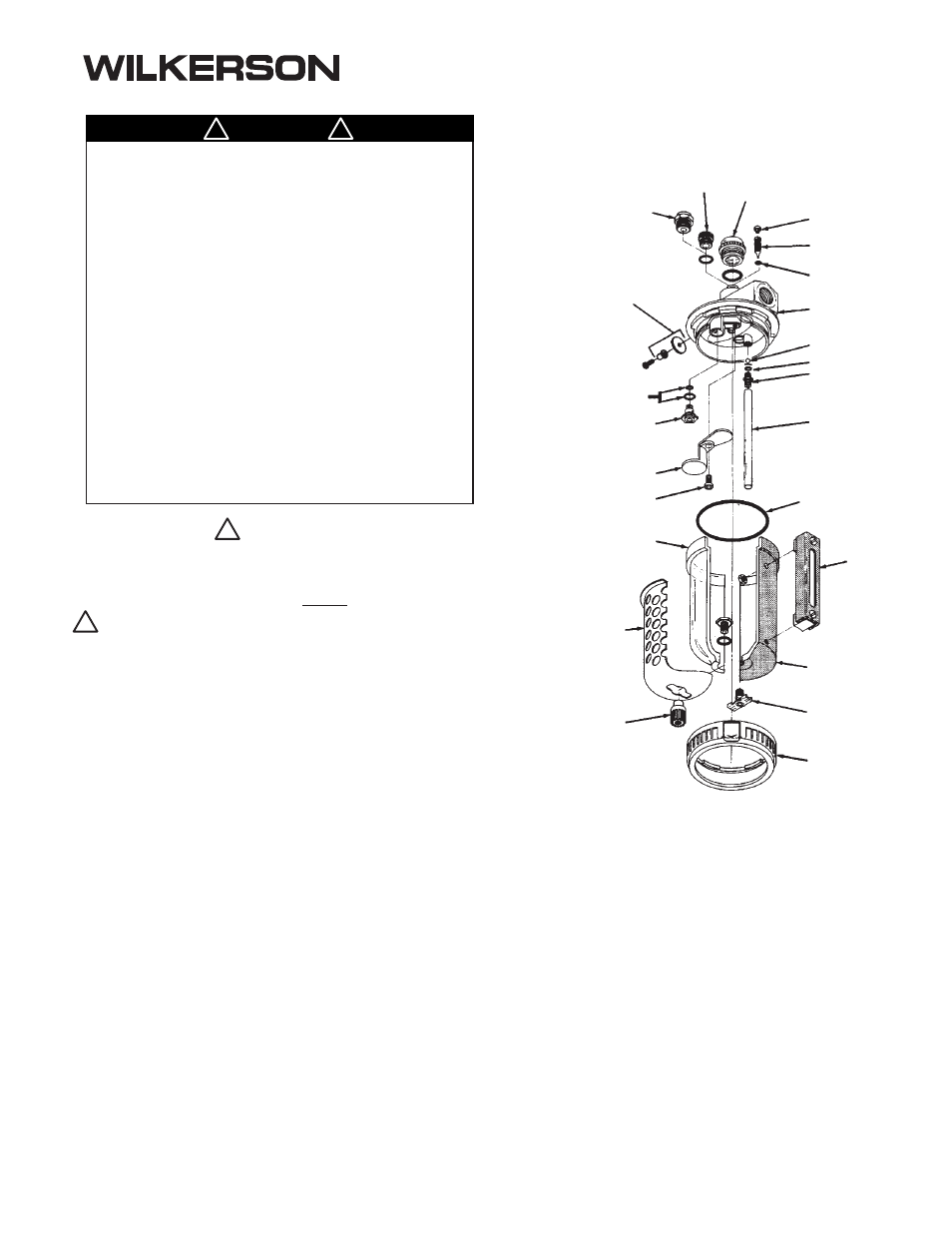

TAMPER-RESISTANT

ADJUSTING

SCREW

O-RING

O-RING

ADAPTER

SIPHON TUBE

BOWL O-RING

BODY NNR

*

BALL

SIGHT GUAGE

METAL BOWL

PETCOCK (for metal

bowl only)

PLASTIC

PETCOCK

NNR

*

(optical with

plastic bowl)

BOWL GUARD

PLASTIC BOWL

SCREW

ATOMIST® ASSEMBLY

O-RING

FLOW-GUIDE®

VARIABLE ORIFICE KIT

(includes screw and

spacer tube)

FORCE-FILL

ADAPTER

FILL PLUG

SIGHT DOME

RECLASSIFIER

NNR

*

CLAMP RING

NNR

*

*

NNR = not normally replaced