Wilkerson L00 User Manual

Installation and maintenance sheet, Lubricator l00 with variations and accessories

WARNING

For information on materials harmful to plastic bowls, contact a Mobay Chemical or

General Electric office for information regarding materials that will

attack polycarbonate plastic.

CAUTION

Certain compressor oils, chemicals, household cleaners, solvents, paints and

fumes will attack plastic bowls and can cause bowl failure. Do not use near

these materials. When bowl becomes dirty replace bowl or wipe only with clean,

dry cloth. Reinstall bowl or buy and install a new bowl. Immediately replace any

crazed, cracked, damaged or deteriorated plastic bowls.

EXCEPT as otherwise specified by the manufacturer, this product is specifi-

cally designed for compressed air service, and use with any other fluid (liquid

or gas) is a misapplication. For example, use with or injection of certain haz-

ardous liquids or gases in the system (such as alcohol or liquid petroleum

gas) could be harmful to the unit or result in a combustible condition or haz-

ardous external leakage. Manufacturer's warranties are void in the event of

misapplication, and manufacturer assumes no responsibility for any resulting

loss. Before using with fluids other than air, or for nonindustrial applications,

or for life support systems consult manufacturer for written approval.

INSTALLATION

1.Refer to above warning.

2.Install as close as possible to the equipment requiring lubrication.

3.Install the unit with the air flowing through the body in the direction

indicated by the arrow.

4.Install a unit with the same pipe-size as the pipeline in use. Avoid

using fittings, couplings, etc., that restrict airflow.

5.The lubricator cannot be filled under pressure. Turn off air pressure,

remove and fill bowl. DO NOT turn the air on until the bowl is firmly in

position.

6.Use only clean, nondetergent oil, SAE 10, or lighter is usually best.

7.The rate of oil delivery may be controlled by turning the adjusting

screw counterclockwise for more and clockwise for less oil delivery.

This lubricator delivers all the oil downstream which passes through

the sight dome. The oil delivery rate will change automatically to deliv-

er more oil during higher airflows and less oil for airflows lower than

that at which the original setting was made.

8.Maximum pressure and operating temperature ratings are: 150 psig

(10,3 bar) and 125°F (52°C); metal bowls, 200 psig (14 bar) and

175°F(79,4°C).

9.Install unit in a vertical position.

MAINTENANCE

1.Given clean operating conditions, this unit will be trouble-free.

Contaminants from dirty oil may collect on the siphon tube inlet filter,

requiring the filter to be cleaned by tapping on a hard surface and

blowing off with an air blow gun.

2.IF THE OIL DELIVERY RATE DROPS, the lubricator should be

cleaned. Shut off the air supply and reduce the pressure in the unit to

zero. Remove the FLOW-GUIDE® orifice screw and clean its

air passage with a small wire. Check the bore that the screw fits into

for contaminant and clean if necessary. Be sure that the passageway

from the sight dome cavity into the FLOW-GUIDE® variable orifice

post is open. Remove the adjusting screw and clean the needle and

seat in the body. Remove and clean the valve seat and the valve

bracket.

3.Drain off any contaminants which collect in the bottom of the bowl.

4.When transparent plastic bowl becomes dirty replace bowl or wipe

only with a dry clean cloth. If plastic bowl shows signs of crazing,

cracking, damage, or other deterioration immediately replace with a

metal bowl or a new plastic bowl and metal bowl guard.

83-104-000 REV A 1/97

EN# 970017 Printed in the U.S.A.

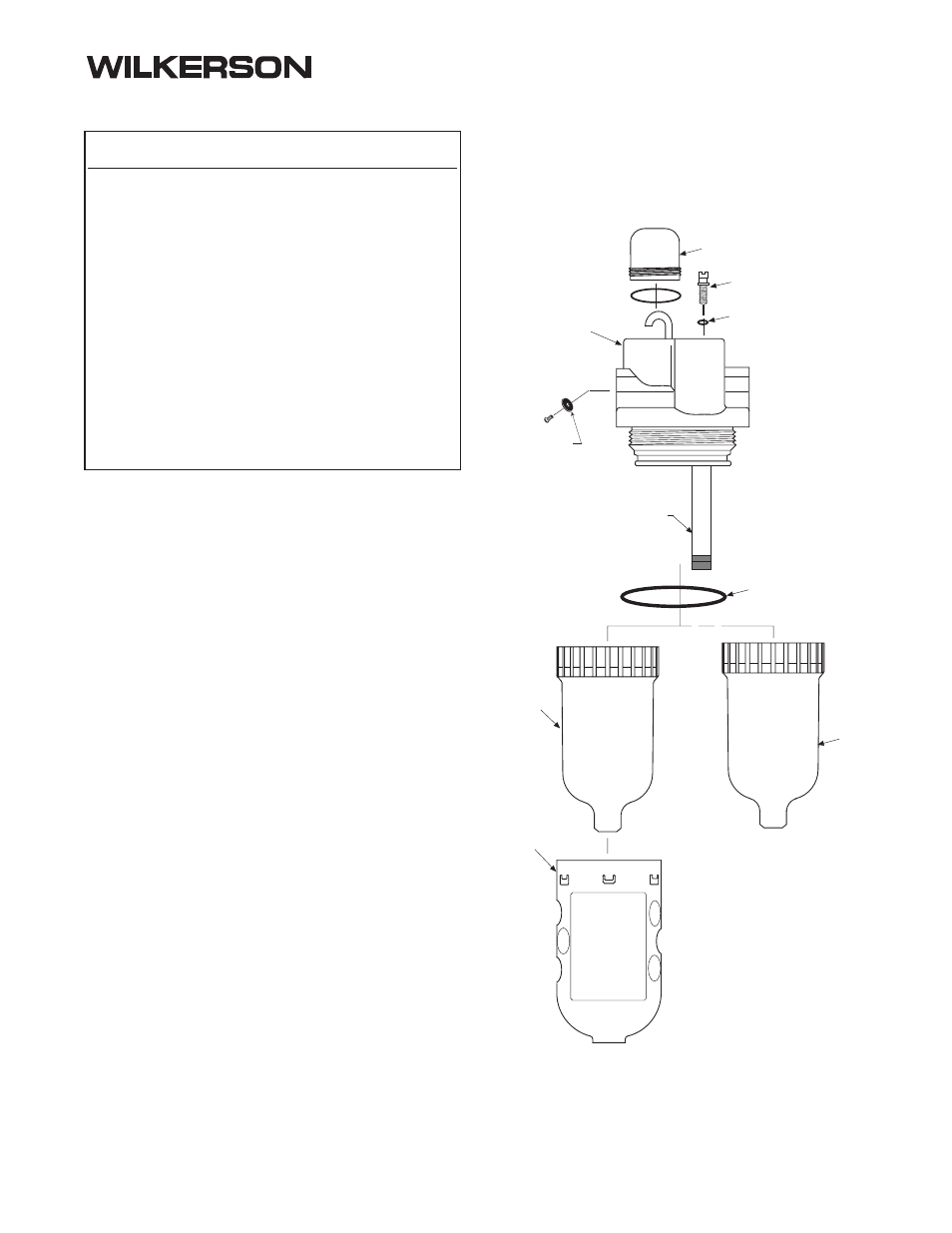

METAL BOWL

GUARD

(Optional)

TRANSPARENT

PLASTIC BOWL

(Includes Bowl

O-Ring)

METAL BOWL

(Includes Bowl

O-Ring)

BODY

NNR

SIPHON

TUBE

SIGHT DOME

KIT

ADJUSTING

SCREW

O-RING KIT

FLOW-GUIDE®

VARIABLE

ORIFICE

O-RING

REPAIR KITS AND REPLACEMENT PARTS

Sight Dome Kit with O-Ring ................................................LRP-95-239

Metal Bowl w/Check Valve .................................................GRP-96-506

Plastic Bowl ........................................................................GRP-95-857

Siphon Tube Assembly .......................................................LRP-95-125

Bowl Guard .........................................................................GRP-96-309

Bowl O-Ring Kit ..................................................................GRP-95-264

ACCESSORIES

Pipe-Mounting Bracket ......................................................GRP-95-734

NNR=NOT NORMALLY REPLACED

INSTALLATION AND

MAINTENANCE SHEET

Lubricator L00 With

Variations and Accessories

®

OPERATIONS