Wilkerson P17 User Manual

Page 2

High Precision Regulator

IS-2R205

Operation

1. Before turning on the air supply, turn the adjusting knob

counterclockwise until compression is released from the control

spring. Then turn on air supply and adjust regulator to desired

secondary pressure by turning adjusting knob clockwise. This

permits pressure to build up slowly, preventing any unexpected

operation of the valve, cylinders, tools, etc., attached to the

line. Adjustment to desired secondary pressure can be made

only with primary pressure applied to the regulator.

2. To decrease regulator pressure setting, always reset from a

pressure lower than the final setting desired. For example,

lowering the secondary pressure from 5.5 to 4.1 bar (80 to

60 PSIG) is best accomplished by dropping the secondary

pressure to 3.5 kPa (50 PSIG), then adjusting upward to 4.1

bar (60 PSIG).

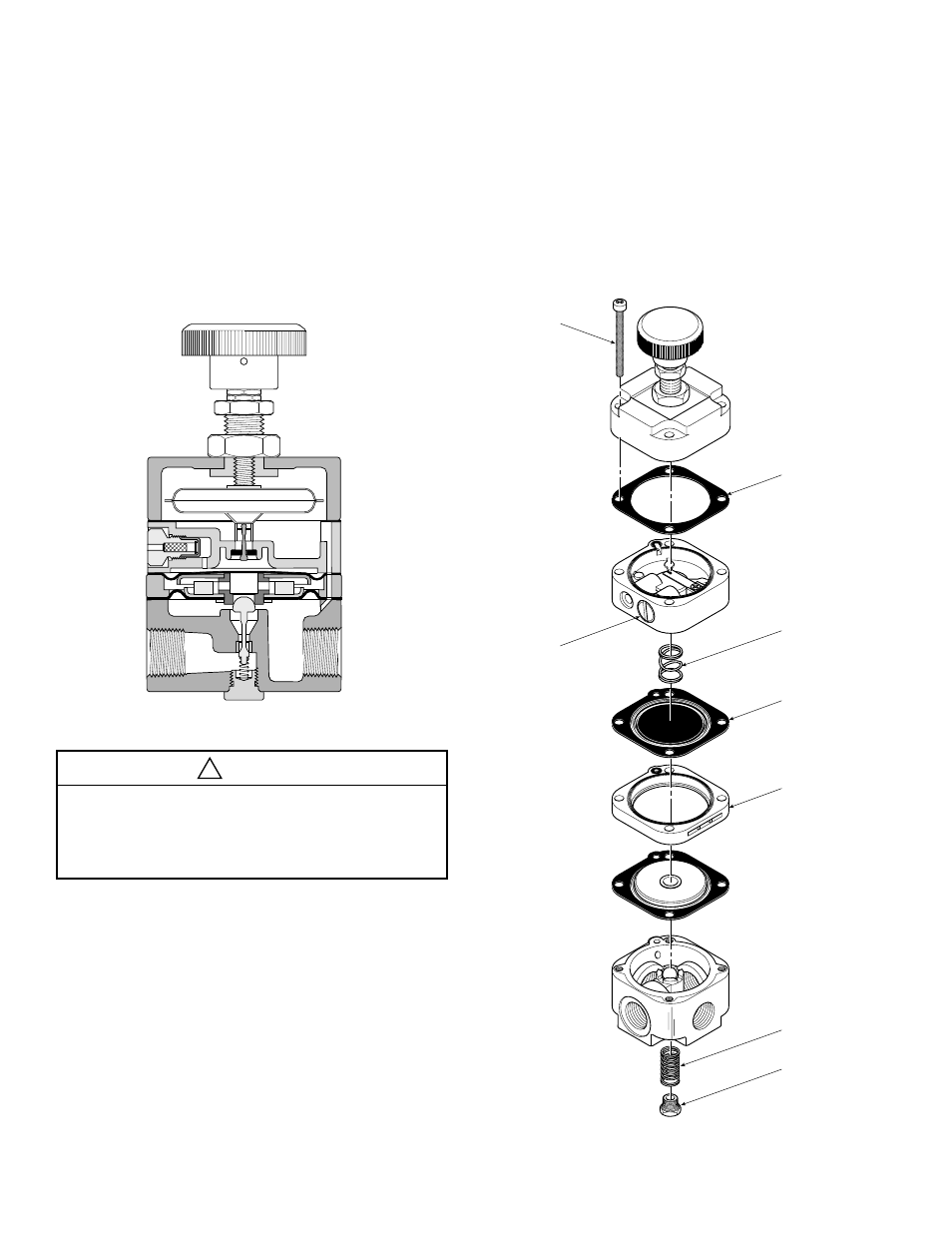

Figure 1

CAUTION

REGULATOR PRESSURE ADJUSTMENT - The working range of

the knob adjustment is designed to permit outlet pressures within

their full range. Pressure adjustment beyond this range is also

possible because the knob is not a limiting device. This is a

common characteristic of most industrial regulators, and limiting

devices may be obtained only by special design.

Service: (Always vent all air pressure

before servicing)

1. Turn the control knob (A) fully counterclockwise. Remove

upstream air supply.

2. Remove four screws (B) holding the bonnet (A) in place.

Remove bonnet assembly, gasket (C), balance control assembly

(D), spring (E), protector diaphragm (F), diaphragm housing

(G), and control diaphragm (H). Discard gasket (C), protector

diaphragm (F), and control diaphragm (H).

3. Remove bleed screw (M) and discard.

4. Remove spring retainer (L) and spring (K).

5. Clean all retained parts with mild soap and water.

6. Install spring (K) and spring retainer (L) into body making sure

that the spring is installed correctly, see Fig. 1. Tighten spring

retainer 2.6 to 3.1 Nm (23 to 27 in-lbs).

!

IN

OUT

A

C*

B

M*

D

E

F*

G

H*

J

L

K

}

}

}

}

* Parts in Service Kit

Figure 2

7. Place the new control diaphragm (H) onto the body (K). Put

diaphragm housing (G) on next followed by the new protector

diaphragm (F) and spring (E). Put balance control assembly

(D) on next then the new gasket (C) followed by bonnet

assembly (A) and reassemble the four screws (B). Tighten

screws 3.2 to 3.6 Nm (28 to 32 in-lbs) in progressive steps

using a crisscross pattern.

8. Install new bleed screw (M). Tighten screw 1.5 to 1.9 Nm (13

to 17 in-lbs) in progressive steps using a crisscross pattern.

9. Admit inlet pressure and turn the adjusting knob (A) to obtain

the desired pressure.

NOTE:A slight flow of air through the bonnet vent hole is necessary

for proper operation of the regulator.