Wilkerson M37 User Manual

Page 2

greater than 50 psid (3,4 bar). To avoid high surges which can either

ruin the element or momentarily allow downstream contamination,

use a slow-opening type valve.

MAINTENANCE

1. The element operates effectively when it is saturated. The element’s

useful life will end only when the DP2 Differential Pressure Indicator

is completely red. The element cannot be cleaned or reused and must

be replaced at the end of its useful life.

2. IF THE UNIT HAS A MANUAL DRAIN, DRAIN THE UNIT ONCE

EVERY 8 HOURS MINIMUM. If the unit is equipped with an automatic

drain clean the screen around the drain. Clean screen by blowing off

with air gun.

3. When bowl becomes dirty, clean with a clean, dry cloth.

4. Before placing the unit in service, make sure that the bowl is

properly reinstalled, and securely bolted in place per noted torque

specification.

REPAIR KITS AND REPLACEMENT PARTS

Filter Element Kit (kit includes filter element, element o-ring, and retainer

o-ring).

Element Types

Type B1

(1 micron)

Type C

(0.01 micron)

Type D

(oil vapor, adsorption)

M35

MSP-95-502

MTP-95-502

MXP-95-502

M36

MSP-95-503

MTP-95-503

MXP-95-503

M37

MSP-95-504

MTP-95-504

MXP-95-504

Drain Plate Kit:

Drain Plate:

(Use with internal automatic

mechanical float drain no. GRP-95-981 ...........................GRP-95-391

Drain Plate (1/2 NPT) ......................................................GRP-95-393

Drain Plate (RC1/2) .........................................................GRP-95-395

Bowl O-ring Kit .....................................................................GRP-95-291

Differential Pressure Indicator (Standard) ........................... DP2-01-001

Differential Pressure Indicator Removal Cap Kit:

(for 300 psig appl.) ...........................................................GRP-95-022

Internal Drains:

Automatic Mechanical Drain:

(Fluorocarbon seals w/ 1/8 NPTstem) .............................GRP-95-981

Automatic Mechanical Drain:

(Fluorocarbon seals w/ R1/8 stem)..................................GRP-96-300

Manual Override for Auto Drain:

(GRP-95-981) NPT Body Threads...................................GRP-96-001

(GRP-96-981) BSPP-G Body Threads ............................GRP-96-101

External Drains:

External Automatic Mechanical Drain ............................... X01-04-000

External Automatic Mechanical Drain ...............................X02-04-F00

External Automatic Mechanical Drain ...............................XB3-04-000

AUTOMATIC ELECTRIC DRAIN VALVE

Model

Number Kit

Port

Size

Orifice

Size

Electrical

Operating

Pressure

Min.

Max.

X20-02-EE00 1/4" NPT 7/16"

115 VAC/1Ph/50-60Hz 2 psig 300 psig

X20-02-ED00 1/4" NPT 7/16" 230 VAC/1PH/50-60Hz 2 psig 300 psig

X20-02-EC00 1/4" NPT 7/16"

24 VDC

5 psig 300 psig

X20-04-EE00 1/2" NPT 7/16"

115 VAC/1Ph/50-60Hz 2 psig 300 psig

X20-04-ED00 1/2" NPT 7/16" 230 VAC/1PH/50-60Hz 2 psig 300 psig

X20-04-EC00 1/2" NPT 7/16"

24 VDC

5 psig 300 psig

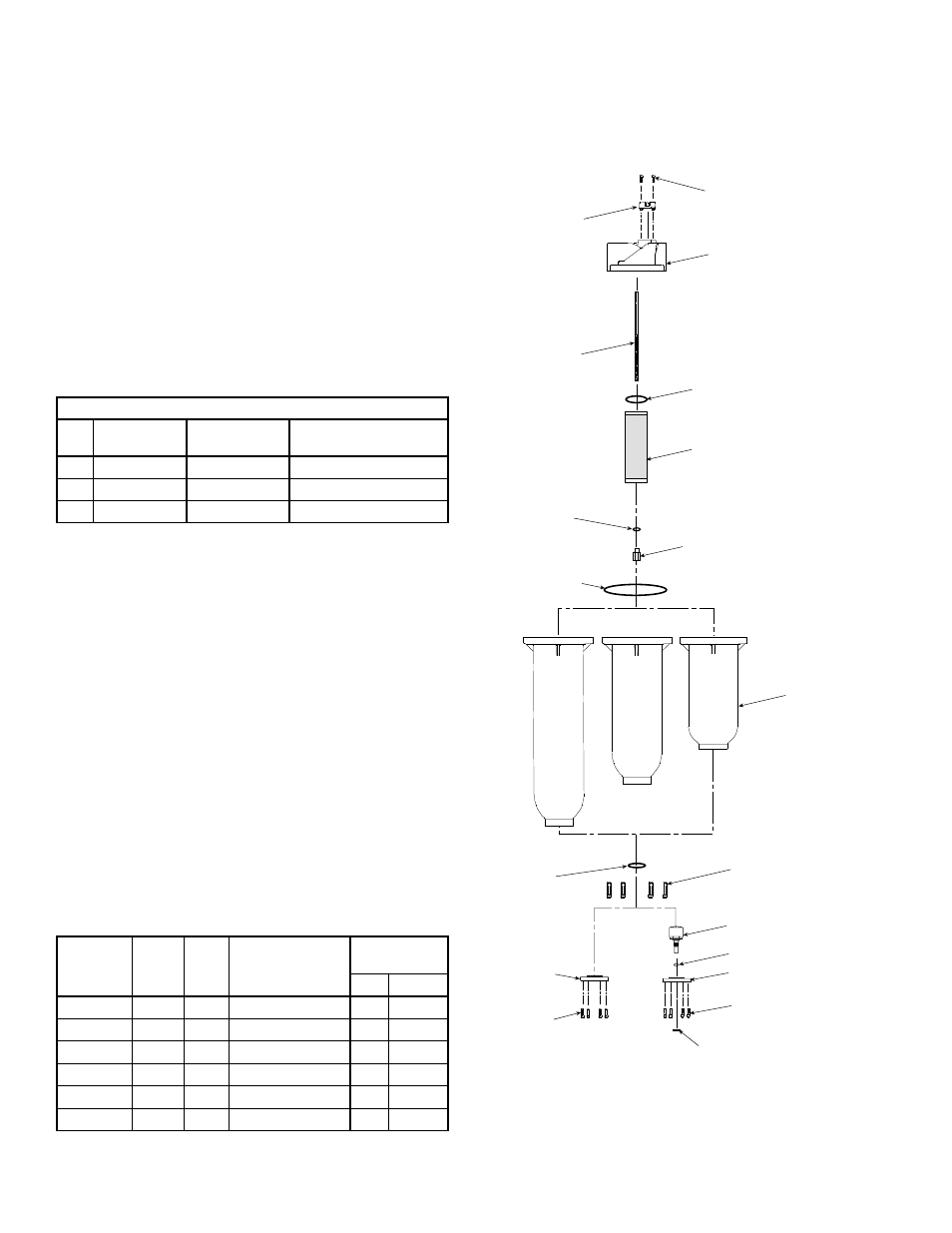

Differential

Pressure

Indicator

Stud

Element

O-ring

O-ring

Cover

O-ring

Screw

(2 Required)

O-ring

Nut

(Torque 8 ± 1 FT.-LB.)

Coalescing

Element

B1,C or

Adsorption Element

D (0.1 vapor removal)

Metal

Bowl

(1 Required)

Screws

(8 Required)

(Torque 54 ± 2 FT.-LB.)

Screws

(6 Required)

Automatic

Mechanical

Drain (Optional)

O-ring

Drain Plate

Drain Plate

Screws

(Torque

16± 2 FT.-LB.)

(6 Required)

Nut