VACUUBRAND VNC 2 E User Manual

Page 35

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

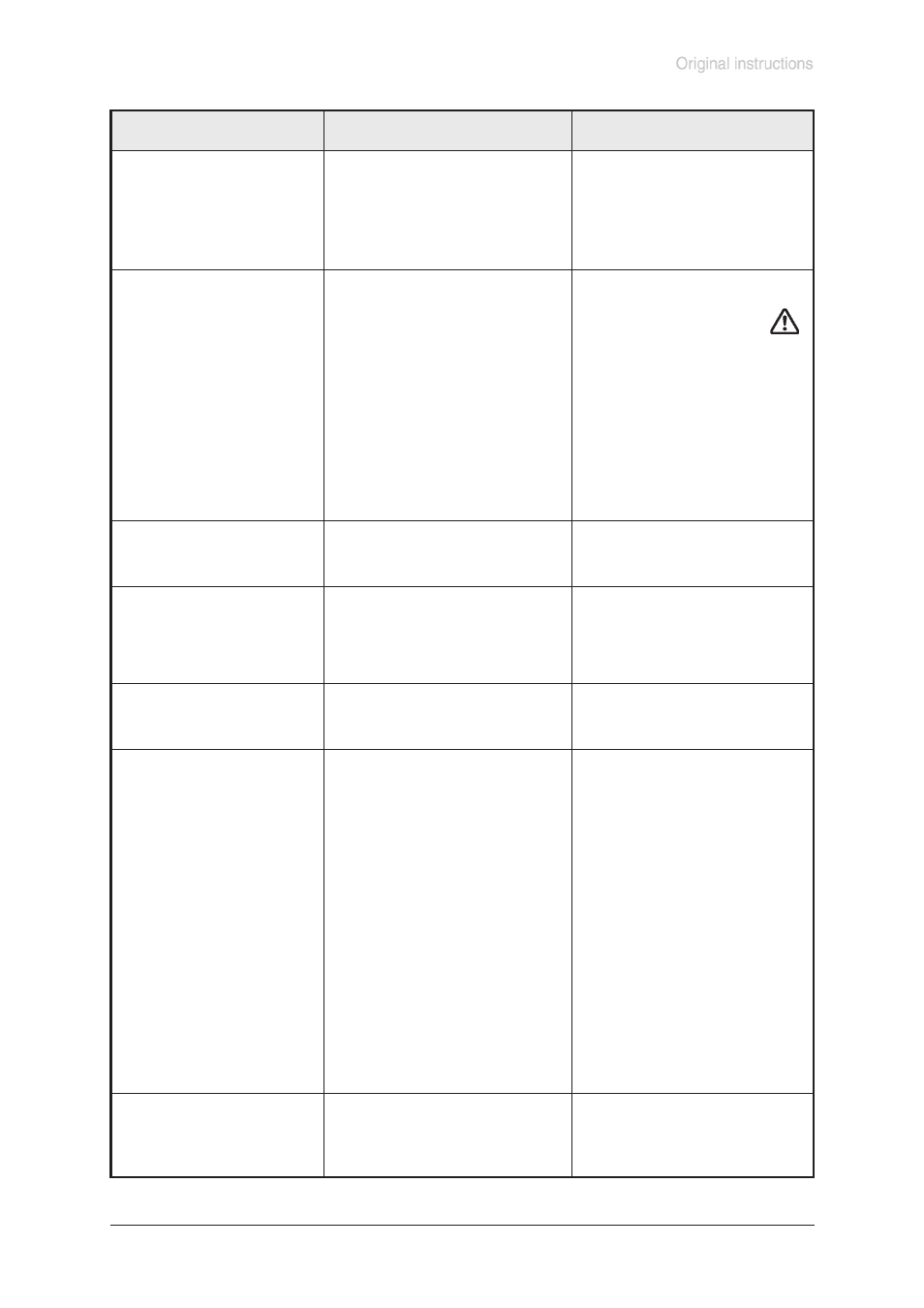

Fault

Possible cause

Remedy

❏ Error message

”ErrValve”, four beeps.

➨ Coolant valve removed or

defective?

✔ Connect or check coolant

valve. In case install a new

coolant valve or configure

controller without coolant

valve. Switch controller off/

on.

❏ Error message

”p Error”, five beeps.

➨ Overpressure at pressure

transducer, pressure >1060

mbar?

✔ Release pressure immedi-

ately! (Risk of bursting!)

➨ External pressure transducer

VSK 3000 removed or defec-

tive?

✔ Connect or check external

pressure transducer. In case

install a new external pres-

sure transducer or configure

controller without external

pressure sensor. Switch con-

troller off/on.

➨ Internal pressure transducer

defective?

✔ Contact local distributor.

❏ Error message

”p RC5-Er”, six peeps.

➨ HYBRID pump RC 5 or RC

6: increased pressure in oil

reservoir?

✔ See separate instructions for

use for RC 5 / RC 6 manage-

ment.

❏ Error message

”ErrTemp.”, seven

beeps.

➨ Excess temperature?

✔ Check configuration and pro-

cess parameters.

➨ Relay circuit defective?

✔ Contact local distributor.

❏ Error message

”CheckSys”, eight

beeps.

➨ Process time in mode

VACUULAN expired?

✔ Check system for leaks. Se-

lect suitable pressure valve.

❏ Error message

”ext. Err”, nine beeps.

➨ Level sensor has set off?

✔ Drain catchpots. Message

disappears. In case, restart

process.

➨ Level sensor has been re-

moved?

✔ Connect level sensor again

or reload a factory-set mode.

➨ External fault indicator has set

off?

✔ Eliminate external error.

➨ External fault indicator has

been removed.

✔ Connect external fault indica-

tor again or switch controller

off/on.

➨ Condenser EK Peltronic has

been removed?

✔ Connect EK Peltronic again

or switch controller off/on.

➨ Excess temperature at con-

denser EK Peltronic? Process

stopped?

✔ Allow condenser EK Peltro-

nic to cool down. In case,

restart process.

❏ Controller does not

respond when operating

any key. No change after

switch off/on.

✔ Contact local distributor.