Troubleshooting – VACUUBRAND VNC 2 E User Manual

Page 34

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999199 / 28/11/2012

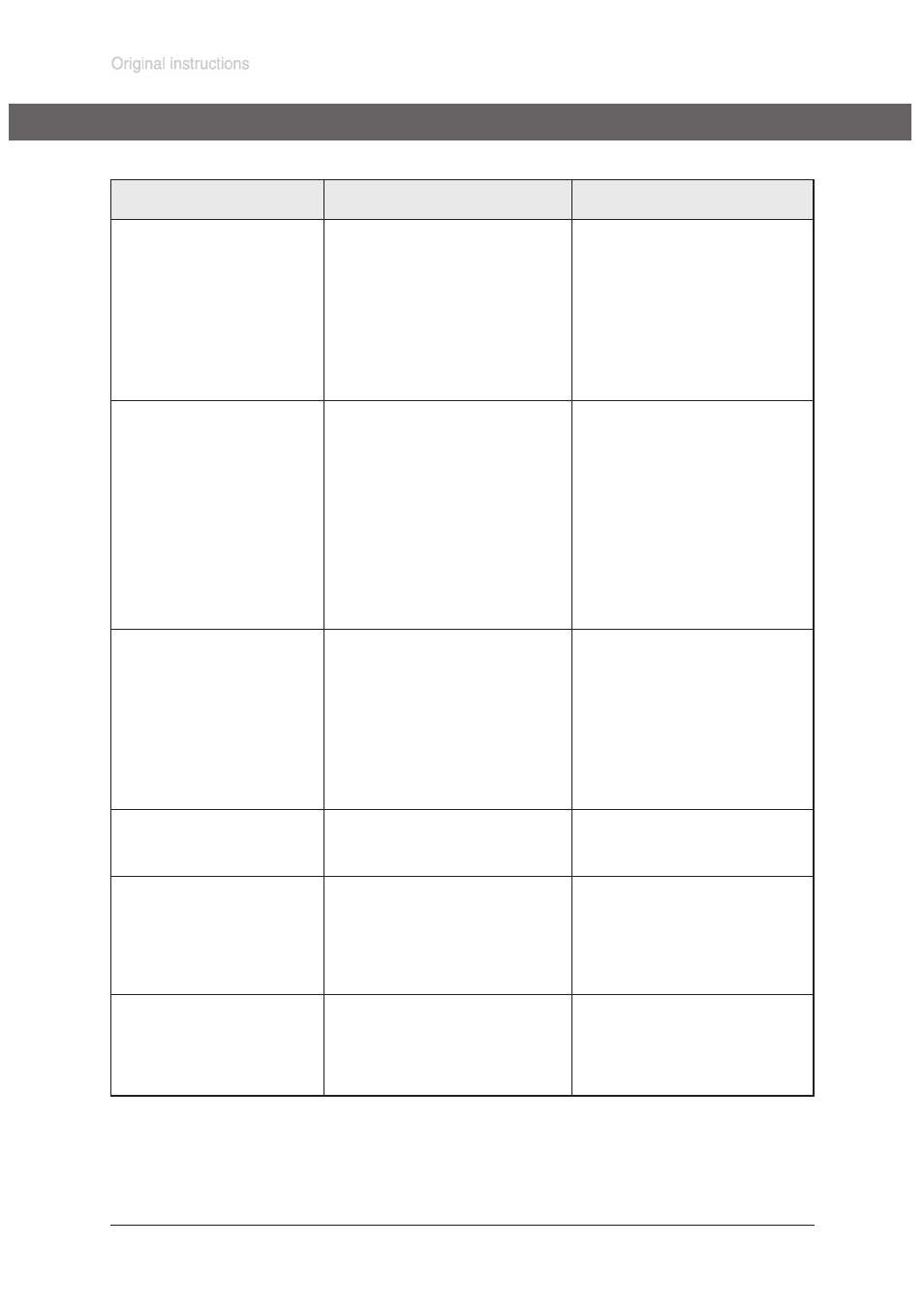

Troubleshooting

Fault

Possible cause

Remedy

❏ No display.

➨ Mains cable not plugged in or

device not switched on?

✔ Plug in mains cable. Switch

device on. Check fuse in

building.

➨ Fuse defective?

✔ Check fuse in building and

fuse at switch output of VNC

2, replace if necessary.

➨ Other causes (device defec-

tive)?

✔ Contact local distributor.

❏ Display disappears, inter-

nal overload protection

activated.

➨ Thermal overload at control-

ler, ambient temperature too

high?

✔ Ensure adequate ventilation.

➨ Short circuit at connected

valves?

✔ Replace valves.

➨ Thermal overload at control-

ler, overload?

✔ Check current draw of con-

nected devices (pumps,

valves).

➨ Other causes (device defec-

tive)?

✔ Contact local distributor.

❏ Pressure reading incor-

rect.

➨ Device not adjusted correctly? ✔ Readjust controller.

➨ Humidity in pressure trans-

ducer?

✔ Let pressure transducer

dry, e.g. by pumping down.

Readjust if necessary. Detect

and eliminate cause.

➨ Pressure transducer soiled?

✔ See „Cleaning the pressure

❏ Controller does not

respond when pressing

keys.

➨ Controller set to remote

mode, ”P“ is displayed?

✔ Control controller via inter-

face or switch off remote

mode.

❏ Error message

”ErrValve”, two beeps.

➨ External venting valve re-

moved or defective?

✔ Connect or check venting

valve. In case install a new

venting valve or configure

controller without venting

valve. Switch controller off/

on.

❏ Error message

”ErrValve”, three

beeps.

➨ In-line valve removed or

defective?

✔ Connect or check in-line

valve. In case install a new

in-line valve or configure con-

troller without in-line valve.

Switch controller off/on.