Checking the ultimate vacuum – VACUUBRAND PC 620 NT plastic housing User Manual

Page 104

page 104 of 113

➨

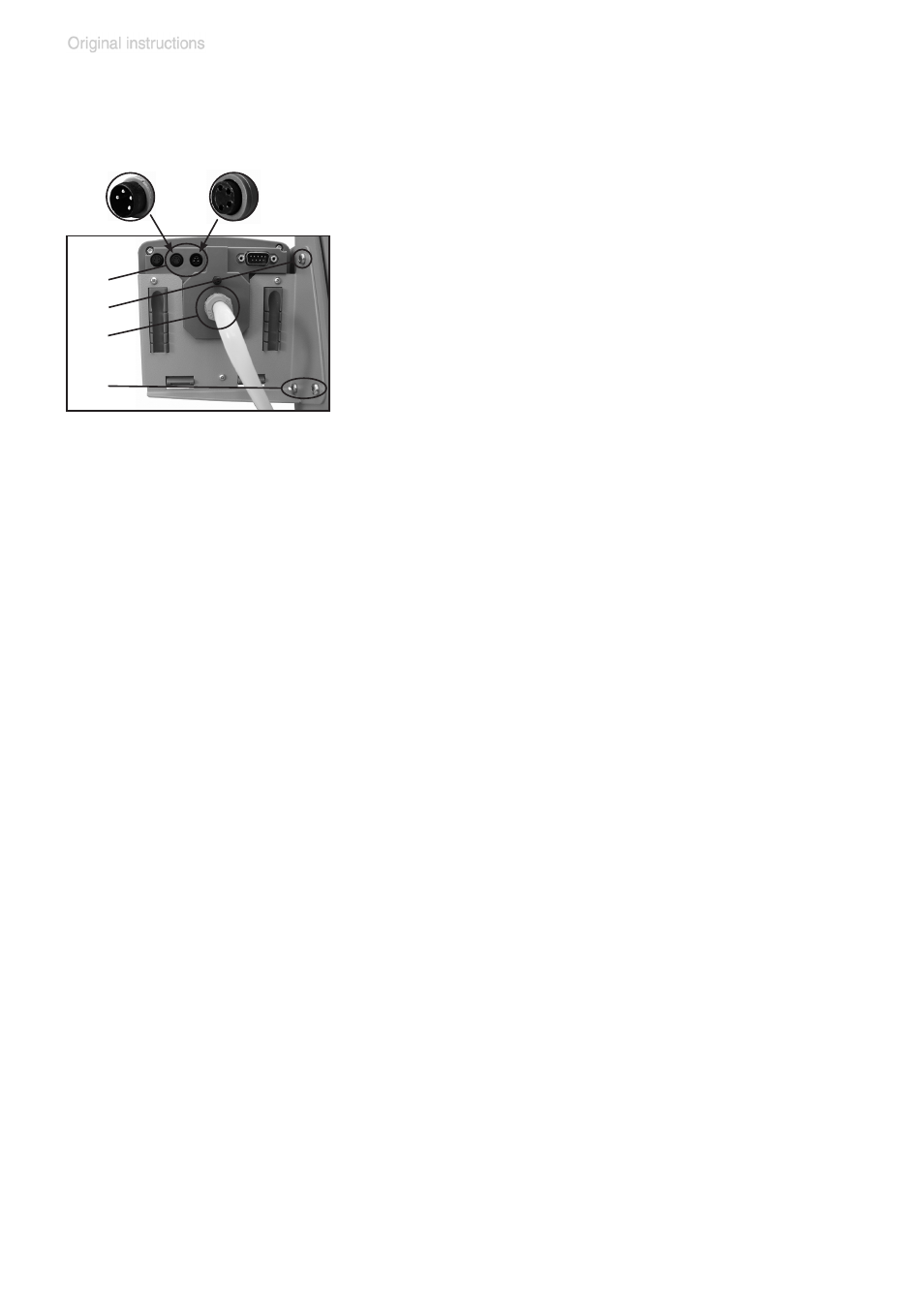

Affix the controller with its holding plate to

the pumping unit (three Allen screws (f), 2.5

mm wide Allen key). Install the washers and

screw the holding plate into position.

➨

Slip the loose end of the PTFE hose onto

the vacuum connection (c) of the CVC 3000

and fasten with union nut.

➨

Plug in the VACUU•BUS lines at the rear of

the controller (b): Power supply line of the

controller (d) and control line of the in-line

valve (e).

Attention: Do not apply off-axis forces when

assembling or removing plug connections!

Observe correct orientation of the plug.

(b)

(f)

(c)

(f)

(d)

(e)

Assembling the second CVC 3000 controller

(only PC 520 NT / PC 620 NT):

If the pump does not achieve the ultimate vacuum:

- Whenever the diaphragms and valves have been replaced, a break-in

period of several hours is required before the pump achieves its ulti-

mate vacuum.

- In case of an unusual noise, switch off pump immediately and check

clamping disc positions.

If the specified ultimate vacuum is not achieved, and if this does not

change after the break-in period:

Check hose connectors at pump heads for leaks. If necessary recheck

valve seats and pump chambers.

Checking the ultimate vacuum

➨

After any intervention at the equipment (e.g., repair / maintenance)

the ultimate vacuum of the pump has to be checked. Only if the pump

achieves its specified ultimate vacuum, the pump’s leak rate is low

enough to ensure that no explosive atmospheres will occur in the inte-

rior of the equipment.

After any intervention at the vacuum sensor the leak rate of the equip-

ment has to be checked.