Assembling the connection hoses – VACUUBRAND PC 301 User Manual

Page 34

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999147 / 17/06/2014

page 34 of 40

➨

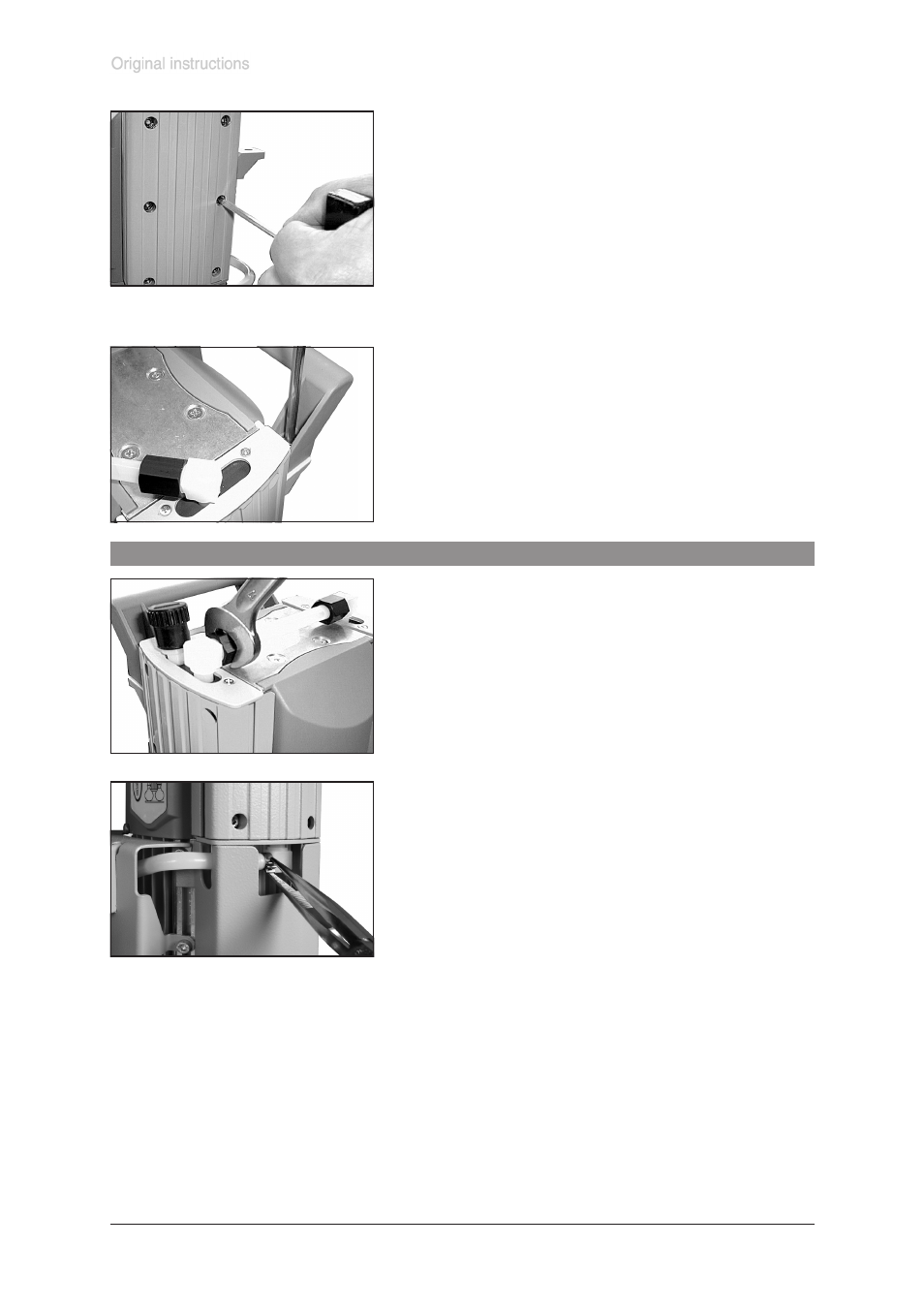

Use open ended wrench w/f 14 to reconnect hose to elbow

fitting.

➨

Tighten union nut first by hand and then tighten one full

turn using open ended wrench w/f 17.

Assembling the connection hoses

➨

Assemble handle.

➨

Position housing cover.

☞

Move housing cover slightly to make sure that the head

covers are correctly positioned.

➨

Screw in six socket head screws fixing housing cover

crosswise first slightly, then tighten.

☞

Do not tighten until head cover is in contact with housing,

max. torque 6 Nm.

Fix the connection tube to the inlet/outlet of the vacuum sys-

tem.

➨

Slip the connecting tube with hose clip onto the hose con-

nection below the housing cover.

➨

Close hose clip with flat pliers.

Replace diaphragms and valves similarly on the other side of the pump.

Fix the hose connection between the inlet and the vacuum

connection of the DVR 2.

➨

Push hose onto vacuum connection and fix with union

nut.

☞

Tighten union nut first by hand and then tighten one full

turn using open ended wrench w/f 17.

Checking the ultimate vacuum

➨

After any intervention at the equipment (e.g., repair / maintenance) the ultimate vacuum of the pump

has to be checked. Only if the pump achieves its specified ultimate vacuum, the pump’s leak rate is

low enough to ensure that no explosive atmospheres will occur in the interior of the equipment.

After any intervention at the vacuum sensor the leak rate of the equipment has to be checked.