Replacing diaphragms and valves, Notice – VACUUBRAND PC 301 User Manual

Page 29

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999147 / 17/06/2014

page 29 of 40

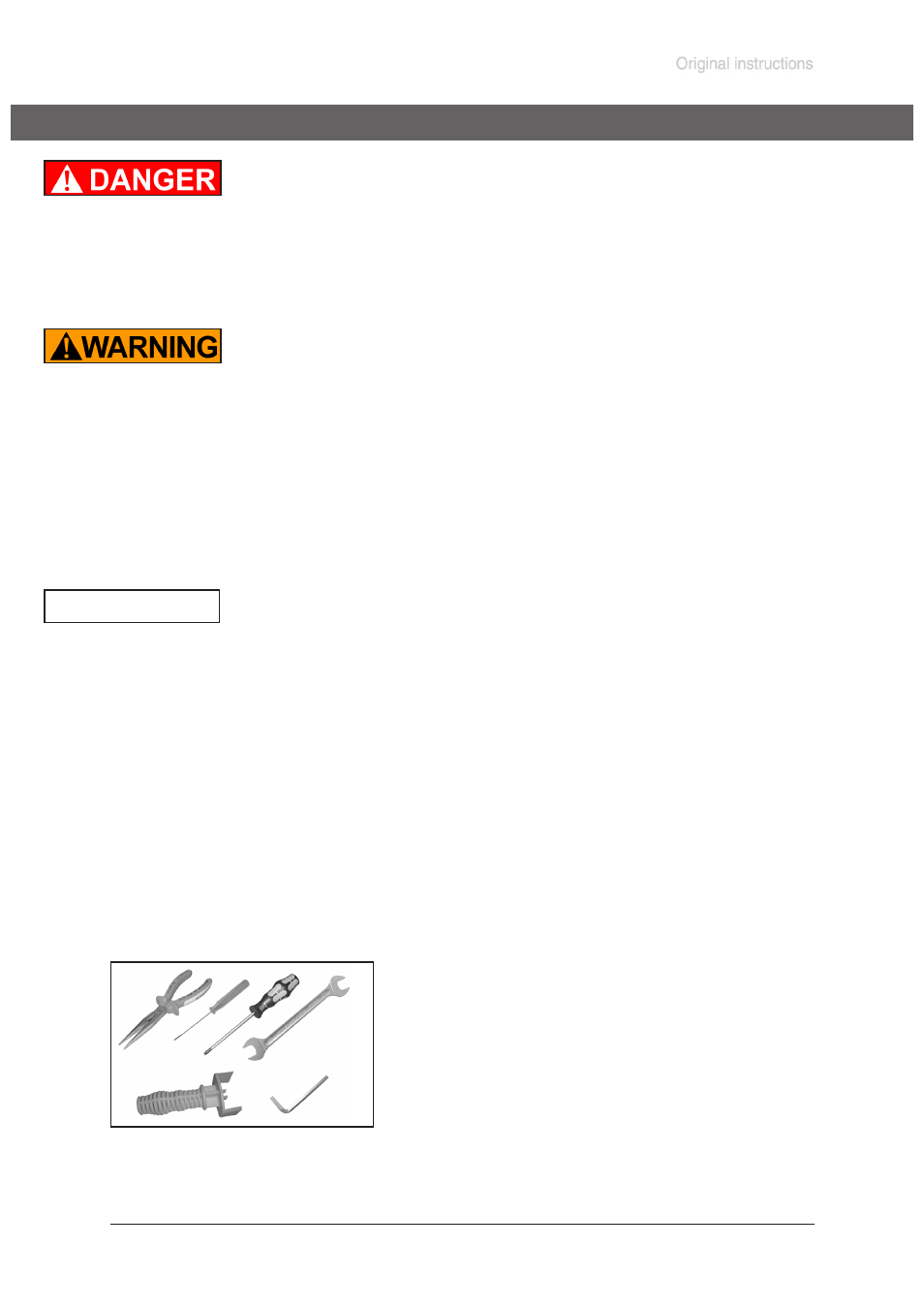

Tools required (metric):

- Diaphragm key w/f 46 (included in set of seals)

- Open-ended wrench w/f 14 / 17

- Hex key size 4 / 5

- Flat-bladed screw driver 2.5 mm

- Flat pliers

☞

Please read section ”Replacing diaphragms and valves” completely before

starting maintenance.

Partially the pictures show pumps in other versions. This doesn’t influence replacing diaphragms and

valves of the pump.

Set of seals (4 diaphragms, 8 valves, diaphragm key) ...........................................................696828

Replacing diaphragms and valves

➨

Never operate the pump if covers or other parts of the pump are disassem-

bled. Ensure that the pump cannot be operated accidentally.

➨

Before starting maintenance,

disconnect the electrical power cord. Wait five

seconds after isolating the equipment from AC power to allow the capacitors to

discharge.

➨

Note: The pump might be contaminated with the process chemicals that have

been pumped during operation. Ensure that the pump is decontaminated before

maintenance. Avoid the release of pollutants.

☞

Never operate a defective or damaged pump.

☞

Take adequate precautions to protect people from the effects of dangerous sub-

stances that may have contaminated the pump and may be released upon disas-

sembly. Ensure that the maintenance technician is familiar with the safety proce-

dures which relate to the products processed by the pumping system.

Use appropriate protective clothing, safety goggles and protective gloves.

☞

Check every motor capacitor regularly by measuring its capacity and estimating

its service life. Replace old capacitors early enough to prevent a failure. The ca-

pacitors must be replaced by a trained electrician.

☞

Allow sufficient cooling of the pump before starting maintenance.

☞

Vent the pump and isolate it from the vacuum system before you start main-

tenance.

Ensure that maintenance is done only by suitably trained and supervised

technicians.

The valves and diaphragms as well as the motor capacitors are wear parts. If the

rated ultimate vacuum is no longer achieved or in case of increased noise level, the

pump interior, the diaphragms and the valves must be cleaned and the diaphragms

and valves must be checked for cracks or other damage.

All bearings are encapsulated and are filled with long-life lubricant. Under normal

operating conditions, the drive system is maintenance free.

In demanding circumstances, it may be efficient to check and clean the pump heads

on a regular basis. In normal use, the lifetime of the diaphragms and valves is typi-

cally 15,000 operating hours.

- Prevent internal condensation, transfer of liquids or dust. The diaphragms and

valves will be damaged if liquid is pumped in significant amount.

- Carry out maintenance frequently if the pump is exposed to corrosive media or in

case of deposits.

- Regular maintenance will improve the lifetime of the pump and also protect both

users and the environment.

NOTICE