Notice – VACUUBRAND PC 301 User Manual

Page 22

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999147 / 17/06/2014

page 22 of 40

In case of overload, the motor is shut down by a

self-hold thermal circuit breaker

in the winding.

Note: Only a manual reset is possible. Switch off the pump and disconnect the elec-

trical power cord. Identify and eliminate the cause of failure. Wait approximately five

minutes before restarting the pump.

•

Note: In case of supply voltage below 100V, the lock of the breaker may not

latch and the pump might restart on its own after sufficient cooling. Take appro-

priate precautions, if an automatic restart of the pump may lead to a dangerous

situation.

A warm up period (approximately 15 min.) is required to ensure that the rated ulti-

mate vacuum and pumping speed are attained. Avoid overheating (e.g., due to hot

process gases).

Attention: Important notes regarding the use of gas ballast

➨

Air and pumped media might react inside the pump or at the outlet of the pump

and form hazardous or explosive mixtures, when you use air rather than inert gas

for the gas ballast. This constitutes a risk of significant damage to equipment and/

or facilities, a risk of personal injury or even loss of life.

☞

Make sure that air/gas intake through the gas ballast valve can never lead to

hazardous, explosive or otherwise dangerous mixtures. If in doubt, use inert gas.

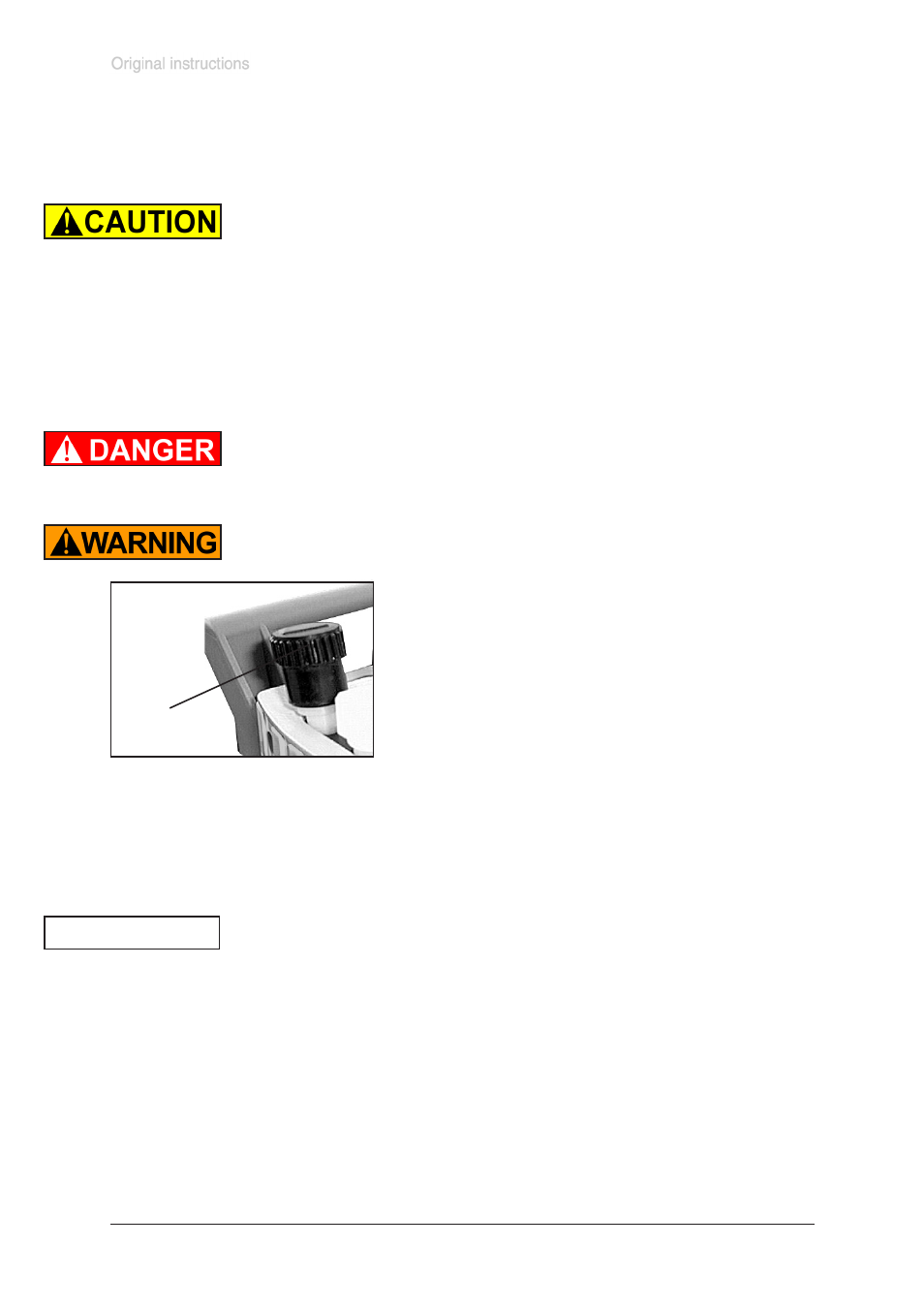

For

condensable vapours (water vapour, solvents, ...):

- Do not pump condensable vapours before the pump has

reached its operating temperature. Do not pump conden-

sable vapours with a closed gas ballast valve.

- Open gas ballast valve. Start pumping vapours only once

the pump has reached its operating temperature.

- The gas ballast valve is open, if the arrow on the gas bal-

last cap points towards the pump.

- With gas ballast valve open, the ultimate vacuum will be

reduced.

- Use inert gas for gas ballast to avoid the formation of ex-

plosive mixtures.

Attention: maximum supply pressure of

inert gas: 1.2 bar absolute.

- Close the gas ballast valve by turning the cap 180°.

In case of low boiling solvents (when the formation of condensate is unlikely), the

use of gas ballast might be unnecessary.

In case of

condensation: Check the liquid level in both catchpots during opera-

tion. Check the liquid level in both catchpots regularly. Do not allow the catchpots to

overfill. Drain catchpots in time to avoid overflow. Install a level sensor (see „Acces-

sories“) for monitoring, if necessary (VACUUBRAND controller CVC 3000 or VNC 2

is required).

The maximum liquid level is at approximately 80% of the total filling level to avoid

problems when removing the catchpots.

Removing the catchpots:

Catchpot at outlet:

Remove joint clip. Remove catchpot and drain condensate.

gas

ballast

NOTICE