Replacing the diaphragm, Replacing the valves and assembling the pump heads – VACUUBRAND PC 301 User Manual

Page 32

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999147 / 17/06/2014

page 32 of 40

☞

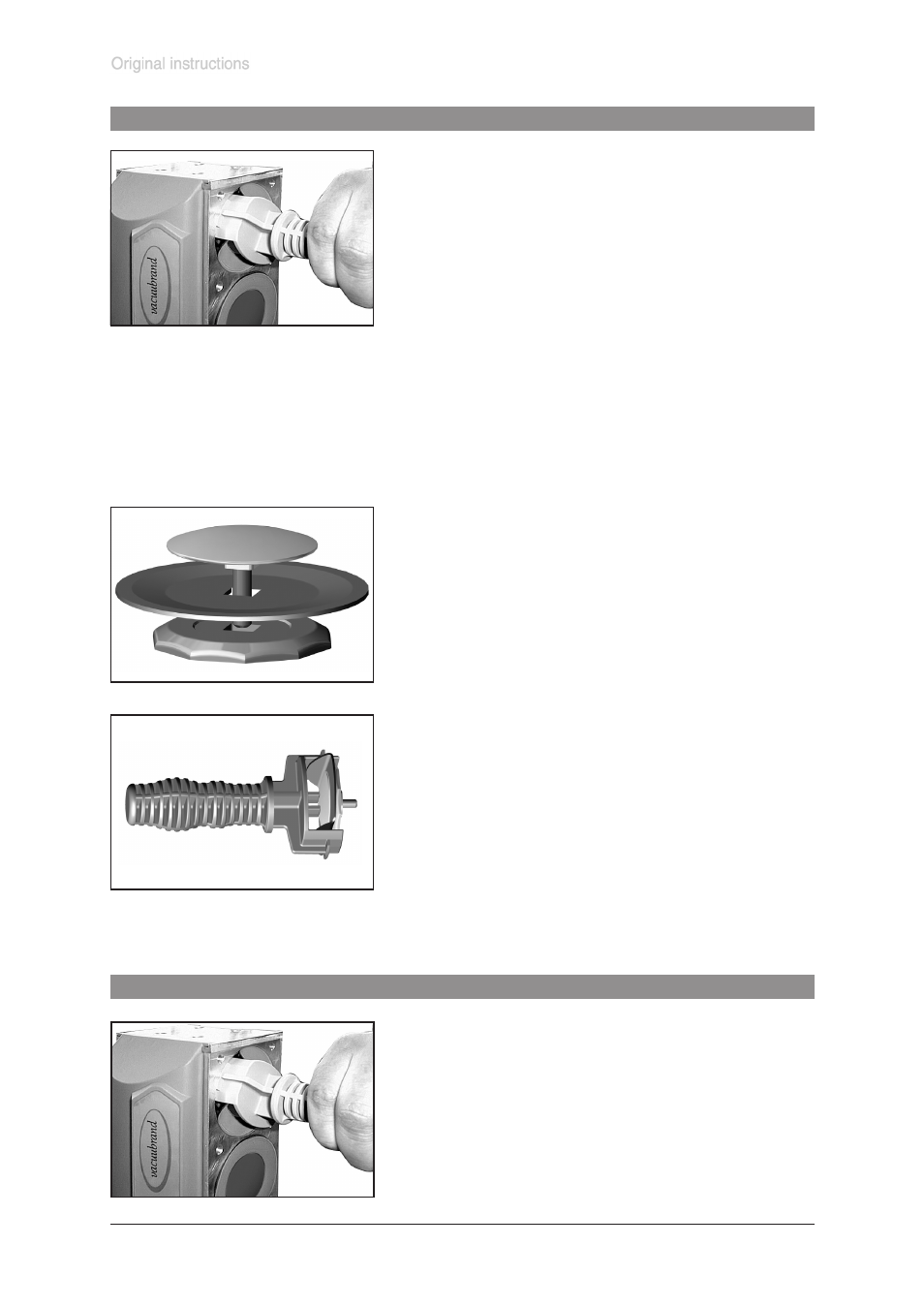

Make sure that the square head screw of the diaphragm

clamping disc is correctly seated in the guide hole of the

diaphragm support disc.

➨

Assemble diaphragm clamping disc, diaphragm and dia-

phragm support disc to connecting rod.

☞

Position washers between diaphragm support disc and

rod.

➨

Lift diaphragm at the side and position carefully together

with diaphragm clamping disc and diaphragm support disc

in the diaphragm key.

☞

Avoid damage of the diaphragm: Do not crack diaphragm

in a way that white lines at the diaphragm upper side oc-

cur.

➨

Check for washers under clamping disc. Do not mix the

washers from the different heads. Make sure that the origi-

nal number is reassembled at the individual pump head.

☞

Smaller number of washers: The pump will not attain final

vacuum. More washers: Clamping disc will hit head cover;

noise or even blockage of the pump.

➨

Position new diaphragm between diaphragm clamping

disc with square head screw and diaphragm support disc.

☞

Note: Position diaphragm with light PTFE side to dia-

phragm clamping disc (to pump chamber).

Replacing the valves and assembling the pump heads

➨

Lift diaphragm carefully.

➨

Apply pressure to the clamping disc beside the diaphragm

to bring connecting rod into upper turning point position if

necessary.

☞

Never use a spiky or sharp-edged tool to lift the dia-

phragm.

➨

Use diaphragm key to grip under the diaphragm to the dia-

phragm support disc.

➨

Apply pressure to the diaphragm clamping disc to bring

the diaphragm into lower turning point position. Press dia-

phragm key against diaphragm clamping disc and unscrew

diaphragm support disc with diaphragm.

☞

If the old diaphragm is difficult to separate from the support

disc, immerse assembly in naphtha or petroleum ether. Do

not inhale!

☞

Check for washers under clamping disc. Do not mix the

washers from the different heads. Make sure that the origi-

nal number is reassembled at the individual pump head.

Replacing the diaphragm