VACUUBRAND MZ 2C NT VARIO without controller (o.C.) User Manual

Page 58

page 58 of 76

➨

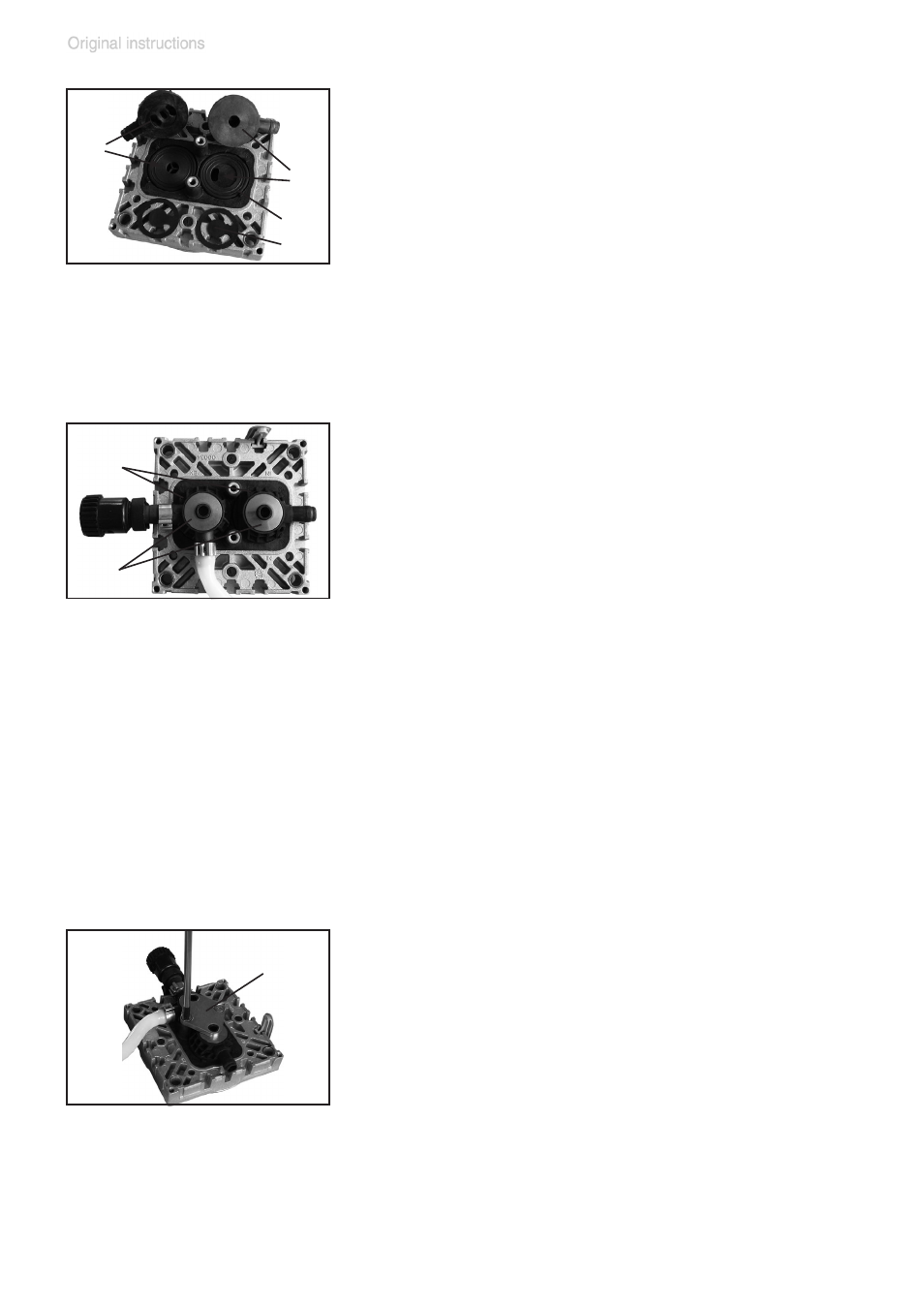

Insert O-rings (M) and valves (N). See fig-

ure for the correct position of the valves:

+

Inlet side (IN):

Marked ”IN” next to the valve seat. The

valve tongue points at the kidney-shaped

orifice in the valve seat.

+

Outlet side (EX):

Marked with ”EX” next to the valve seat. The

valve is oriented the same direction as the

valve at the inlet side.

EX

IN

➨

Position valve heads (O), with hose nozzle

(P), if applicable, connection tube or con-

nection fastener (Q), and disc springs (R)

on the valve seats. Position disc springs

with large opening downwards. Pay atten-

tion to the correct orientation of the valve

heads.

+

Center the valve head with respect to the

valve seat. The valve head must lie flat on

the valve seat.

M

N

O

R

➨

Position clamping bracket (S) with counter-

sunk bores facing upwards.

➨

Align the countersunk bores with the thread-

ed pegs.

➨

Loosely fasten the countersunk screws and

correct the alignment of the valve heads if

necessary.

➨

Tighten countersunk screws with Torx screwdriver T20.

+

Torque: 2.2 ft

.

lb

f

(3 Nm).

Valve head with gas ballast or hose nozzle connection:

➨

Insert square nut (K) in the groove of the head cover (J) or position

square nut in the groove and then screw on connection fastener.

+

Loosely fasten fillister head screw (L).

S

- MV 10C VARIO-B without controller (o.C.) ME 4C NT VARIO without controller (o.C.) MD 4C NT VARIO without controller (o.C.) MD 12C VARIO-B without controller (o.C.) PC 3012 VARIO without controller (o.C.) PC 3010 VARIO without controller (o.C.) PC 3004 VARIO without controller (o.C.) PC 3003 VARIO without controller (o.C.) PC 3002 VARIO without controller (o.C.)