VACUUBRAND MZ 2C NT VARIO without controller (o.C.) User Manual

Page 38

page 38 of 76

+

Improves vacuum performance in applications with

condensable vapors.

PC 300x VARIO:

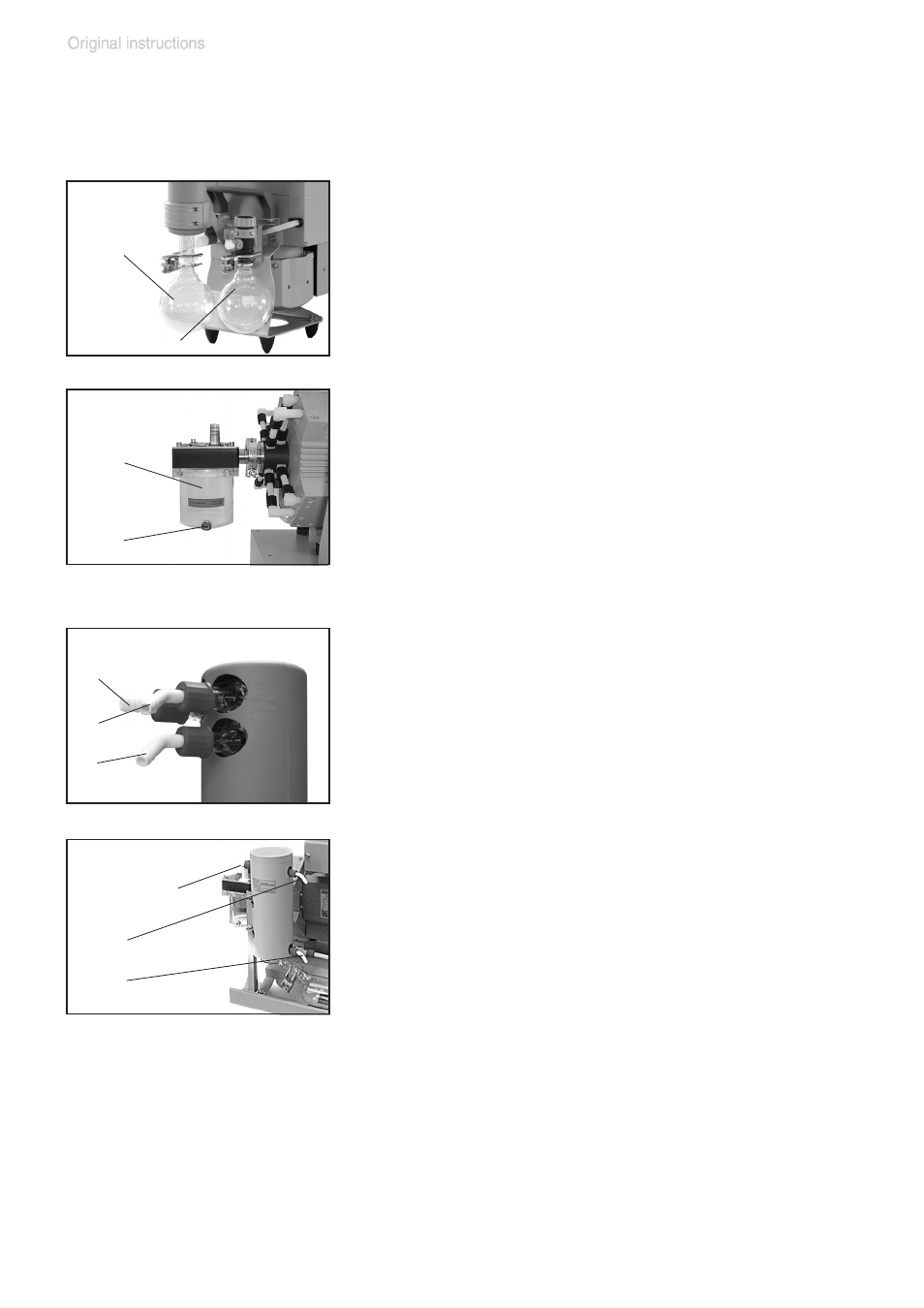

Both catchpots (14) are coated with a protec-

tive layer to protect against shattering in case

of breakage or implosion.

➨

Assemble the catchpots at the inlet and at

the outlet using joint clips.

PC 301x VARIO:

➨

Assemble the inlet catchpot (18) with cen-

tring ring and clamping ring at the inlet of

the pump.

➨

Assemble the collecting flask (20) at the

exhaust waste vapor condenser using the

joint clip.

Exhaust waste vapor condenser:

➨

Assemble the hose nozzles for coolant inlet

(15) and coolant outlet (16) tubing and for

the gas outlet (8) at the exhaust waste va-

por condenser.

The

exhaust waste vapor condenser en-

ables an efficient condensation of the pumped

vapors at the outlet.

+

No backflow of condensates.

+

Controlled recovery of condensates.

+

Close to 100% solvent recovery.

+

The isolation cover protects against glass

splinters in case of breakage, acts as ther-

mal isolation to avoid condensation of hu-

midity and is intended to absorb shocks.

➨

Attach the tubing of the coolant circuit to the respective

hose nozzles (hose nozzles for tubing I.D. 1/4”-5/16”

(6-8 mm), see image) at the waste vapor condenser.

catchpot at

outlet

catchpot at inlet

(18)

(19)

(15)

(16)

PC 300x VARIO

outlet (gas!) (8)

(15)

(16)

outlet (gas!) (8)

PC 301x VARIO

- MV 10C VARIO-B without controller (o.C.) ME 4C NT VARIO without controller (o.C.) MD 4C NT VARIO without controller (o.C.) MD 12C VARIO-B without controller (o.C.) PC 3012 VARIO without controller (o.C.) PC 3010 VARIO without controller (o.C.) PC 3004 VARIO without controller (o.C.) PC 3003 VARIO without controller (o.C.) PC 3002 VARIO without controller (o.C.)